The compression in the internal combustion (IC) engine cylinders takes place,

When air and gas get mixed. The process is necessary for the car to move and function. If there’s low compression in one cylinder,

You will face many problems including misfiring at the time of starting the car or weak engine performance. How to stop this from happening? Well, before you know how to fix low compression in one cylinder,

You should have basic ideas about the reasons that cause the problem.

Top 5 Causes of Low Compression in One Cylinder

Understanding the causes of the problem will help you to identify the source of troubles and repair it. Learning these problems will give an insight on how to fix,

Low compression in one cylinder.

Cracked Cylinder Wall

It will trigger poor compression, leading to poor engine performance.

To spot the complication,

Crank the engine with the radiator cap open and,

Watch out if air bubbles coming out. These bubbles are gases from the combustion chamber;

That leak into the cooling system through the cracked wall.

Read More:

Gasket Issues

Worn out or misaligned gasket could also be the reason for poor compression. You can use a pressure tester to pinpoint the trouble in this case. It measures the compression level in the cylinder. If the readings are different,

You should check the gasket to locate the problematic spot.

Read More:

- Detecting Head Gasket Issues And The Solution

- Symptoms Of A Blown Head Gasket? How To Prevent And Fix It

Decrepit Timing Belt

It is the bridge between the camshaft and crankshaft. The camshaft cannot function when the belt breaks or fails. As a result, the intake valve won’t close and the exhaust valve gets sealed. The chain reaction will lead to trapping of the gases inside;

The combustion chamber and cause low compression.

Read More:

- Timing Belt vs Timing Chain

- Easy Ways To Replace Timing Belt At Home

- What Happens When a Timing Chain Breaks While Driving

- The Different Types Of Car Belts And Their Functions

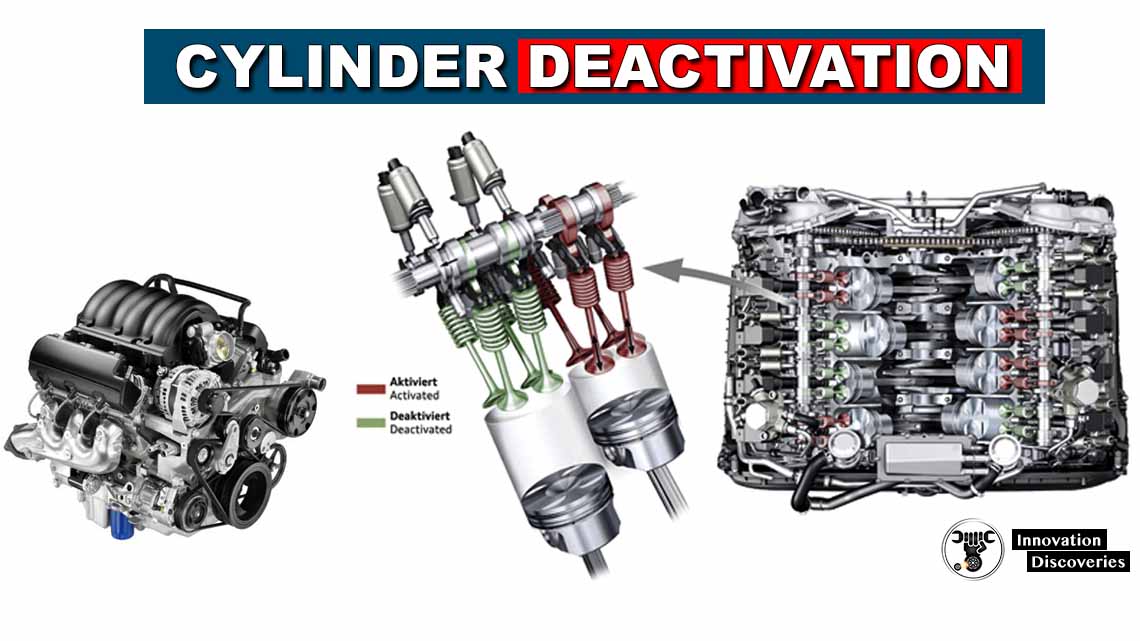

Valve Problems

Crank the engine with a compression tester in the place of the spark plug to

Identify any issues with the valve. Watch out for gas leakage from either the air inlet manifold,

Or the exhaust pipe. Leakage sound from any of them will confirm,

That the valve attached to that respective system is faulty.

Read More:

- Symptoms of a Bad EGR Valve (and Replacement Cost)

- Idle Air Control Valve Symptoms – A Full Technical Guidance

- Automatic Transmission Valve Body Functions And Failure Symptoms

Worn Pistons or Piston Rings

When these parts are worn out,

The gases from the cylinder get into the engine’s crankcase through them.

One way of testing the issue is to pour viscous oil to the spark plug hole;

So, that it reaches the combustion cylinder. If the compression increases,

The problem is with the piston or piston rings.

Read More:

How to Fix Low Compression in One Cylinder

The first step to repair is to be sure that the compression in,

One of the engine cylinders is low.

Use a compression gauge to check the measurement.

In case you don’t have one,

Take the car to an auto servicing shop.

So, a mechanic can do the testing.

If you find low compression, the next step is to check the cylinder,

Valves, gasket,

And piston as you already knows the problem could originate from these areas.

If you can detect any crack, damage, or slit,

Be ready for a costly and lengthy engine repair or replacement job.

Also, read:

- Common Rail Diesel Engine: Working Principle, Pros and Cons

- What is an engine block?

- How do gasoline engines differ from diesel engines?

- Homogeneous Charge Compression Ignition (HCCI) engine

One Comment