Introduction:

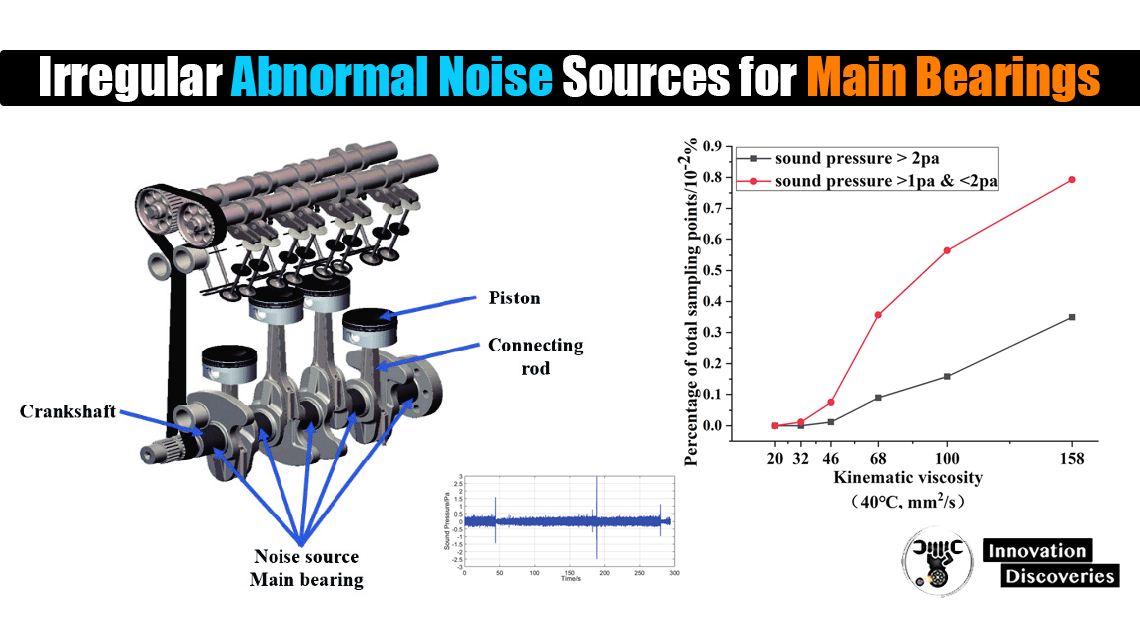

Main bearings are vital components within engines, supporting the crankshaft and ensuring smooth operation.

However, when irregular abnormal noises emanate from these bearings, it can be indicative of underlying issues that require prompt attention.

In this article, we delve into the various causes behind irregular abnormal noise sources for main bearings, exploring the potential implications and solutions.

Understanding Main Bearings:

Before delving into irregular abnormal noises, it’s crucial to grasp the significance of main bearings.

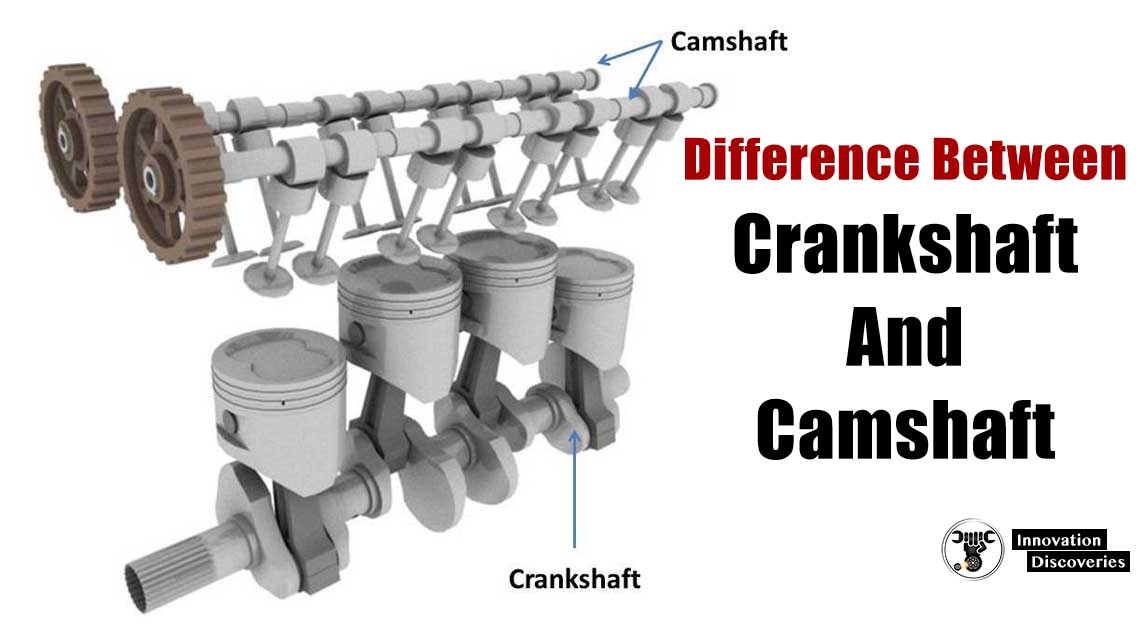

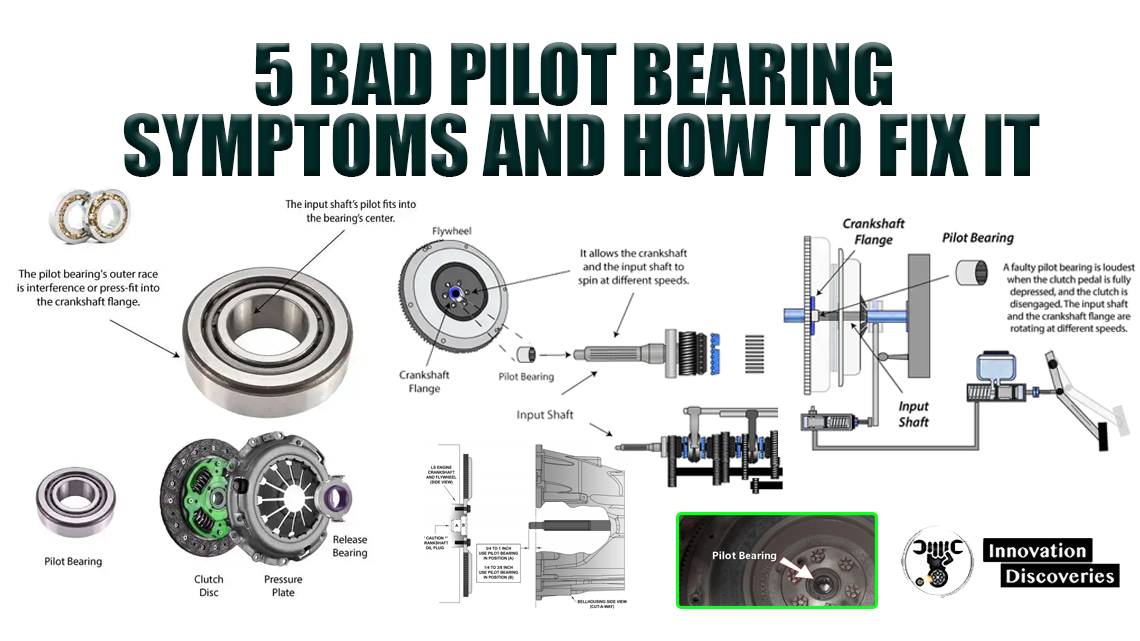

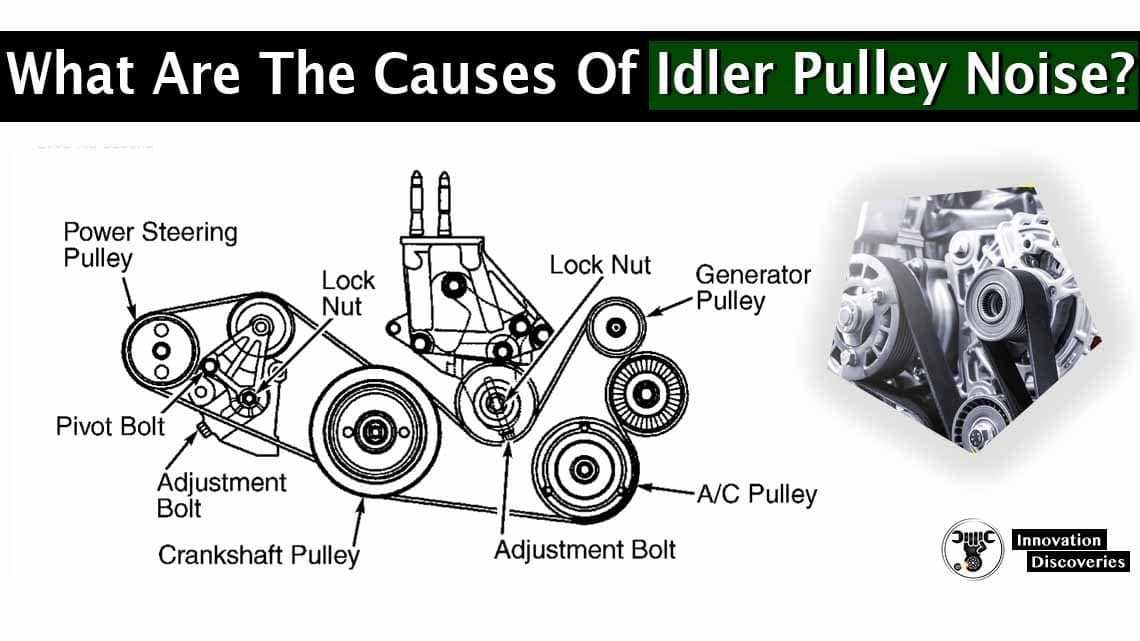

These bearings are positioned between the crankshaft and engine block, providing support and reducing friction during engine operation.

Their proper functioning is essential for maintaining engine performance and longevity.

Types of Abnormal Noises:

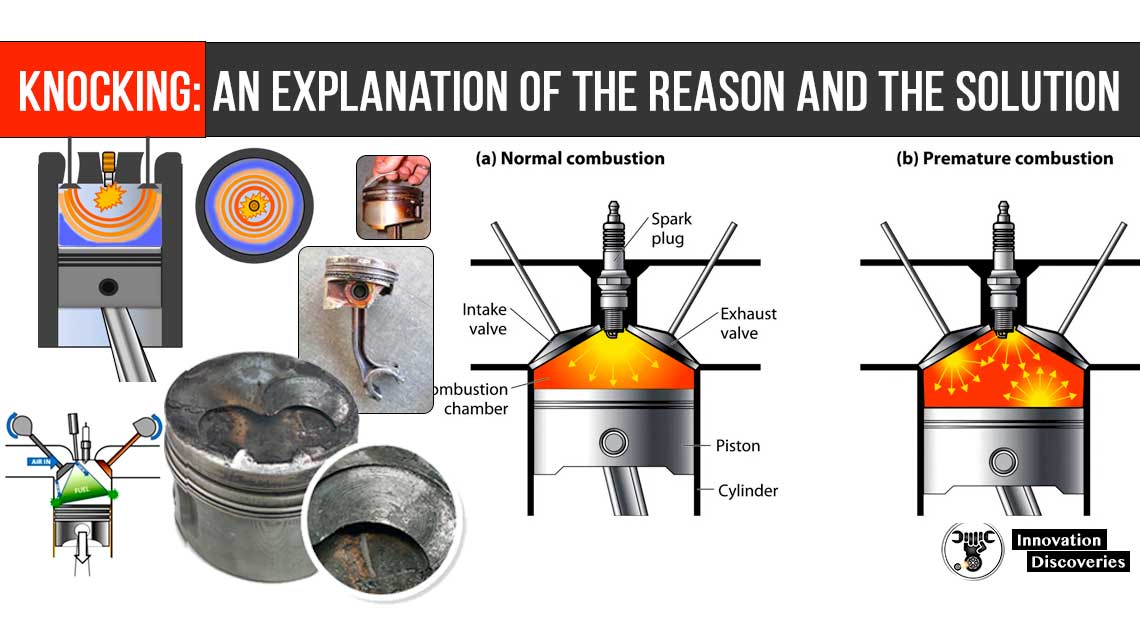

1. Knocking:

Irregular knocking noises may indicate issues such as worn bearings or improper lubrication.

This can result from metal-to-metal contact due to insufficient lubrication or excessive wear, leading to a knocking sound as the crankshaft rotates.

2. Whining or Whirring:

High-pitched whining or whirring noises can signify problems like inadequate lubrication, misalignment, or damaged bearings.

These noises may intensify with engine speed and can indicate imminent bearing failure if left unaddressed.

3. Grinding or Growling:

A grinding or growling noise often points to severe bearing damage, possibly caused by contaminated oil, excessive heat, or prolonged wear.

This noise suggests significant friction and metal-on-metal contact, necessitating immediate inspection and repair.

4. Clicking or Ticking:

Clicking or ticking sounds can result from various issues, including loose components, worn bearings, or insufficient lubrication. While not as severe as grinding noises, they still warrant investigation to prevent further damage.

Causes of Irregular Abnormal Noises:

1. Insufficient Lubrication:

One of the primary causes of abnormal bearing noises is inadequate lubrication. Without proper lubrication, bearings experience increased friction, leading to wear and potential failure.

This can result from low oil levels, poor-quality oil, or oil contamination.

2. Contaminated Oil:

Contaminants such as dirt, metal particles, or water can infiltrate the engine oil, compromising its lubricating properties and causing abrasive wear on bearings.

Regular oil changes and the use of high-quality oil filters can help mitigate this issue.

3. Misalignment:

Improper alignment of engine components, including the crankshaft and bearings, can lead to uneven stress distribution and premature wear.

Misalignment may occur due to manufacturing defects, improper installation, or structural damage.

4. Overloading:

Excessive loads or operating conditions beyond the bearing’s capacity can accelerate wear and cause abnormal noises.

This may occur in high-performance engines, towing applications, or under extreme driving conditions.

5. Temperature Extremes:

Extreme temperatures, whether excessively high or low, can affect the viscosity of the engine oil and impair its ability to lubricate effectively.

Inadequate cooling or overheating can also exacerbate bearing wear and contribute to abnormal noises.

6. Wear and Tear:

Over time, normal wear and tear can degrade bearing surfaces, leading to irregularities that produce abnormal noises.

Regular maintenance, including inspections and component replacements, is crucial for preventing excessive wear and ensuring optimal engine performance.

Addressing Irregular Abnormal Noises:

1. Inspection:

Upon detecting abnormal noises, it’s essential to conduct a thorough inspection of the engine, focusing on the main bearings and surrounding components.

Visual examination, oil analysis, and diagnostic tests can help identify the underlying cause of the noise.

2. Maintenance:

Routine maintenance practices such as oil changes, filter replacements, and bearing inspections are critical for preventing abnormal noises and prolonging bearing life.

Following manufacturer recommendations and using quality lubricants are essential for optimal engine performance.

3. Repairs:

Depending on the severity of the issue, repairs may range from simple adjustments, such as tightening loose components, to more extensive measures like bearing replacement or engine overhaul.

Prompt action is crucial to prevent further damage and ensure safe operation.

Conclusion:

Irregular abnormal noises originating from main bearings can signal potential issues that require immediate attention.

By understanding the various causes behind these noises and implementing proactive maintenance practices, engine owners can mitigate the risk of bearing failure and prolong the lifespan of their equipment.

Vigilance, regular inspections, and adherence to manufacturer recommendations are key to ensuring optimal engine performance and reliability.

Discover More:

Visit Forum

Visit Our Friendly Website