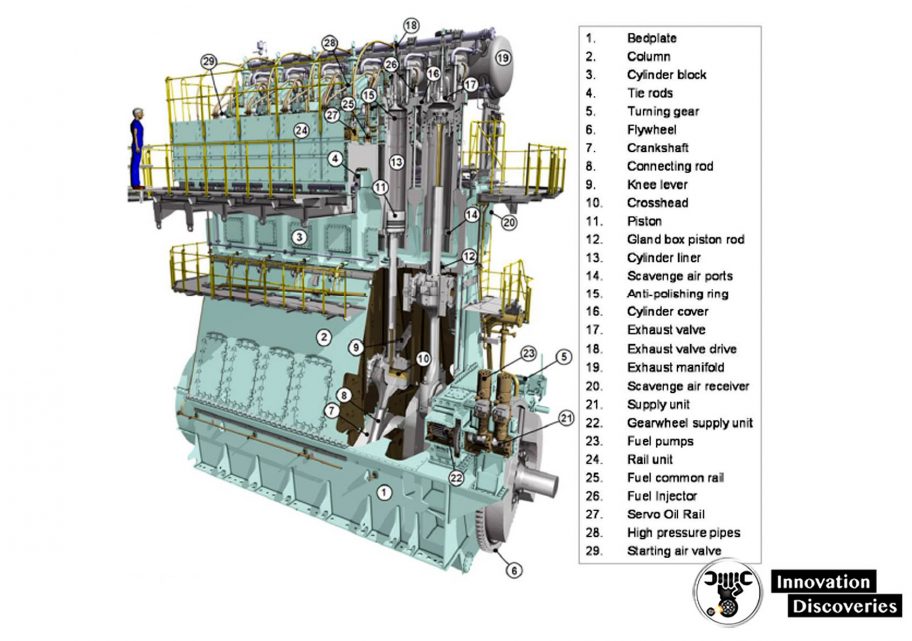

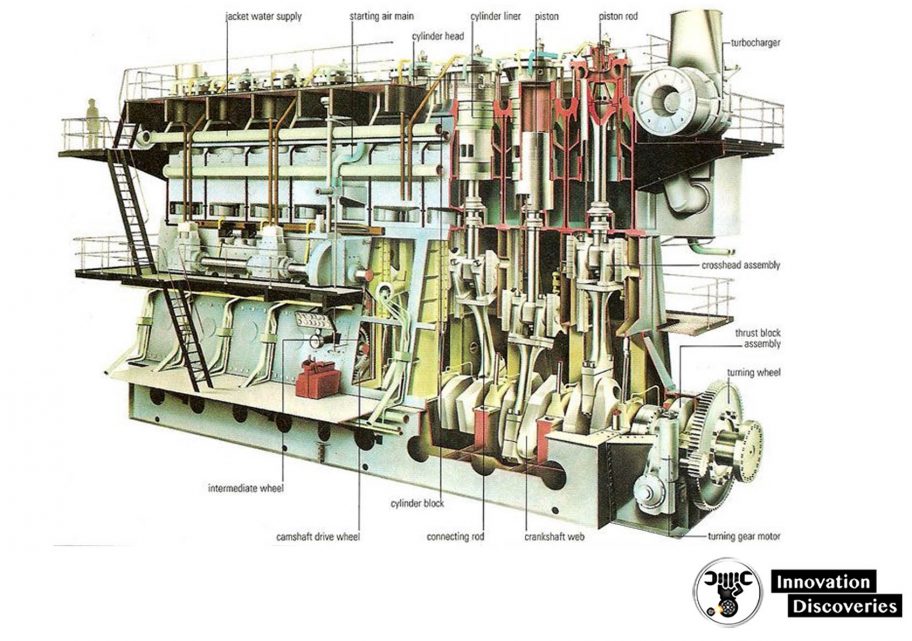

1. Bed Plate:

The bed plate provides the rigid seating of the crankshaft, which is essential for satisfactory engine operation.

The bed plate is constructed of a deep longitudinal girder (running along the length of the engine) and a transverse girder or cross girder (running across the engine).

The transverse and longitudinal girders are joined together by welding.

They are made up of:

- Transverse Girder: Cast iron.

- Longitudinal Girder: Mild steel

2. Frame:

Frames are provided for supporting the engine mountings, and an individual frame is fitted to each cross girder. Frames are made up of mild steel plates and tubes.

3. Holding Down:

The engine bed plate is supported on a series of chocks made up of Cast Steel / Epoxy Resin and the holding down bolts passes through the bed plate, chock, and tank top plating made up of UTS Steel.

4. Guide:

Guides are provided in the crosshead assembly. They have two main parts, and they are made up of the following materials:

- Guide Bar: Mild Steel / Cast Iron

- Guide shoe: White Metal Lined

5. Cylinder Parts:

Cylinder Liner:

- Material: Pearlitic Grey Cast Iron

The Properties of Cylinder Liner Material:

- Material for liners must provide adequate strength and fatigue life.

- Resist abrasion and corrosion and must readily transfer heat.

- Be able to retain a film of lubricating oil on working surfaces.

- Have a rate of thermal expansion compatible with adjacent parts.

To meet these requirements, liners are cast in pearlitic grey cast iron to which alloying elements such as vanadium and titanium are added to enhance strength, wear, and corrosion resistance.

- Chrome-plated liners have an extended life, but the initial cost is higher.

- Chrome-plated piston rings must not be used with chromium-plated liners.

Cylinder cover:

- Material: pearlitic or nodular graphite cast iron or steel.

Properties:

- Must be of sufficient strength to withstand the gas load at maximum pressure.

- Resist bending and be symmetrical in shape.

- Have a rate of thermal expansion compatible with adjacent parts and transfer heat readily.

Cylinder head bolt

- High UTS Steel

Tie bolt

- High UTS Steel

6. Piston Parts:

The piston has different parts, and they are made up of the following materials:

Piston:

- Crown: Chrome Molybdenum Steel/Nickel Chrome Steel

- Piston Skirt: Cast Iron

- Rings: Cast Iron/Ordinary Grey Cast iron

- Piston Rod: Cast Steel

- Wear Ring: (Lead-Bronze)

Materials used for pistons required similar properties to those for cylinder liners and cylinder covers.

Properties of Piston Crown material:

- High mechanical strength to withstand a high gas load.

- Long fatigue life to survive the fluctuating mechanical and thermal stress.

- High thermal conductivity and low coefficient of expansion.

- High surface properties, i.e., hardness, anti-corrosive.

- The metal must resist high-temperature creep, corrosion, and erosion.

Properties of piston ring material:

- Highly mechanical strength and good tension properties.

- Elasticity and wear resistance with low friction.

- Must be corrosion resistance with low friction.

- Must be corrosion resistance and resistance against high temperatures.

- self-lubricating properties.

- Must readily transfer heat and be compatible with cylinder material.

- Compatible with piston for thermal expansion to maintain ring groove clearances.

7. Crankshaft

Materials: These are some of the commonly used materials to build the crankshaft.

- Low alloyed Cr –Mo steel, which has a tensile strength of (590-680) N/mm2.

- Unalloyed Carbon Steel (Normalized).

- Mild steel (cast-throw).

- Carbon steel (forged or cast).

- Nickel steel (forged).

Properties of crankshaft materials:

Besides strength, the material should have a high endurance limit to fatigue failure.

The material should be capable of a good surface finish.

must be,

- hardened to resist the wear of journals and crank pins.

- It is tough to carry a load.

- rigid to resist the bending of the shafts.

But it should confirm the bearing line alignment.

8. Exhaust Valve

The exhaust valves are made up of the following materials:

Exhaust valve:

- Spindle: Nimonic Material

- Lid: Nimonic Material

- Seat: Stellite Material

- Cage: Pearlitic Cast Iron

- Guide: Pearlitic Cast Iron

- Bush: Bronze

9. Stuffing Box

- Upper Rings: Bronze Alloy

- Lower Rings: Cast Iron Alloy

10. Camshaft

- Steel Alloy with Hardened Surface

11. Connecting rod bolt

- High UTS Alloy Steel

12. Bearing

- White metal alloy

Turbo Charger is also important part of marine Diesel Engine. Also, there are timing gears system which regulates engine firing order and provides drive to the cam shaft.

There are heat exchangers for cooling the freshwater in place of radiators of non-marine diesel engines.

Visit Forum

Visit Our Friendly Website