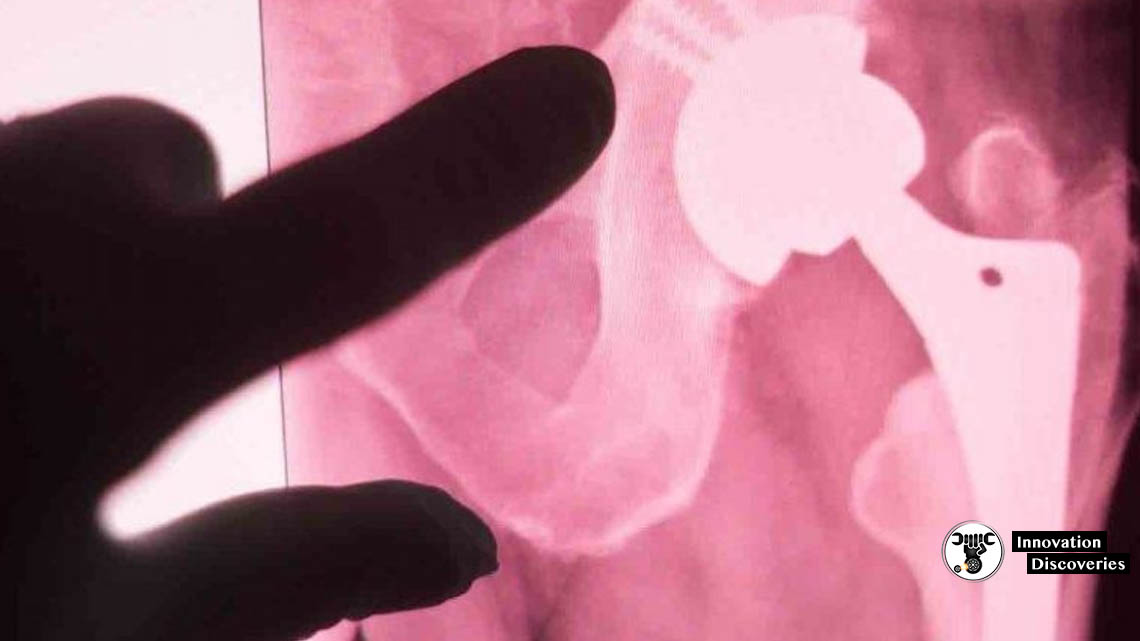

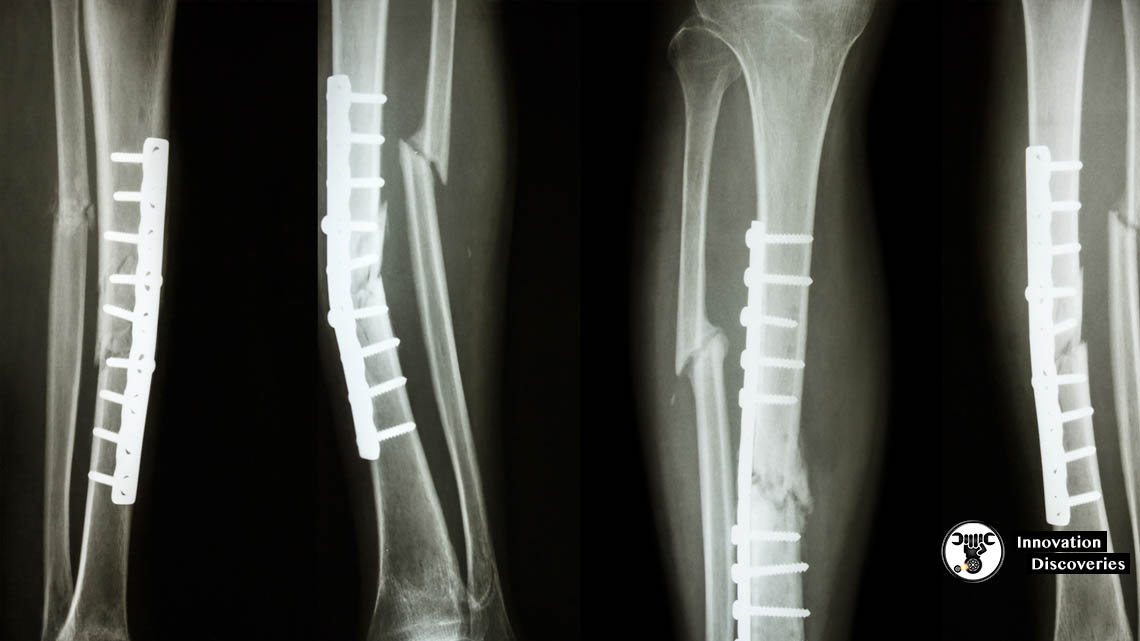

If you have ever had a broken arm or leg, you know how long and how painful the process of healing is. Crews and pins are often inserted to hold the pieces of broken bone together while it heals. The new technology involves 3D printing ceramic implants that hold the fractured bones together while turning into actual bone themselves. These implants were created by Hala Zreiqat and her colleagues at the University of Sydney in Australia.

The implants were initially tested in broken arm bones in rabbits and were successful in repairing the bone. A study which is under the process of being published shows that the team also tested these implants in large leg fractures in sheep. Even though the sample was small, the team was encouraged by the fact that the experiment was equally successful in all the eight animals involved in the study. The scientists claim that the sheep were able to walk immediately after the surgery of planting implants.

They did, however, walk with a plaster cast to improve stabilization throughout the healing process. Complete healing was observed in 25% of the fractures three months after the surgery and the number went up to 88% in a years’ time. As the bones grew back, the scaffolds of the initial implants dissolved gradually. The composition of the implants is similar to that of a bone and that is why it is able to dissolve without any nasty side effects.

The implant is porous and acts as a scaffold that natural bone and blood vessels can grow through making it perfect to restore the bone. The implant is made up of calcium silicate, the mineral gahnite, and small amounts of strontium and zinc which are trace elements in natural bone. Once the research is published and further trials are done, we might see it become a common practice and a broken bone would no longer be a nightmare.