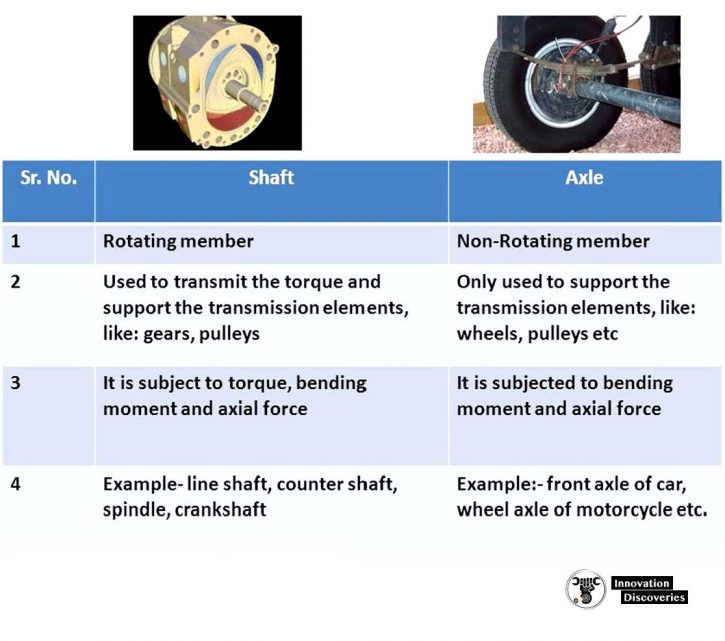

SHAFT

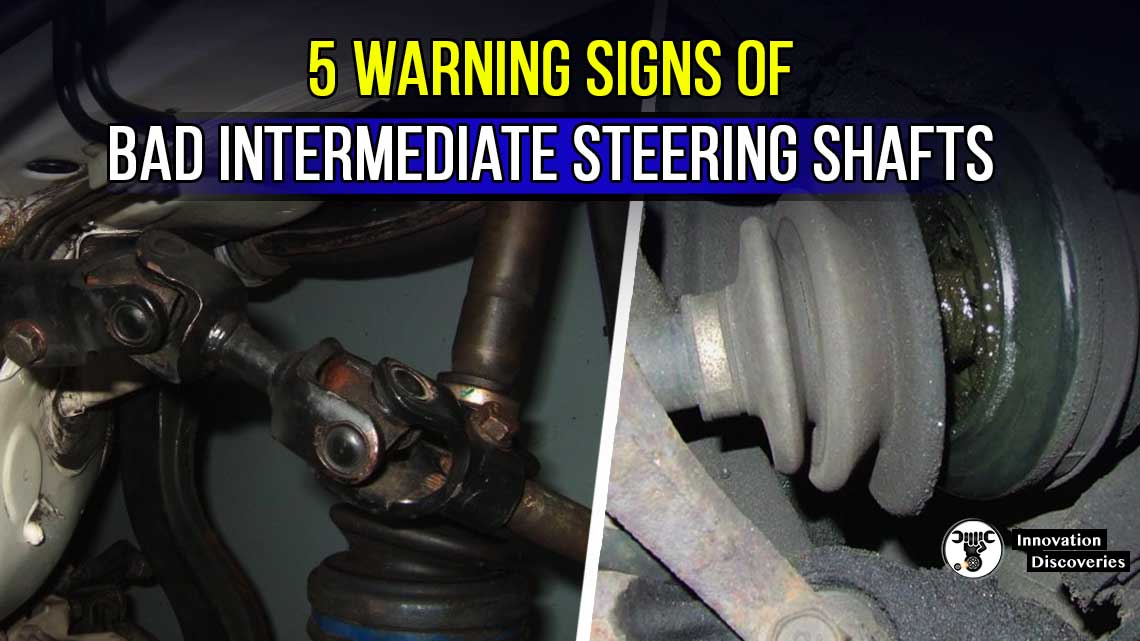

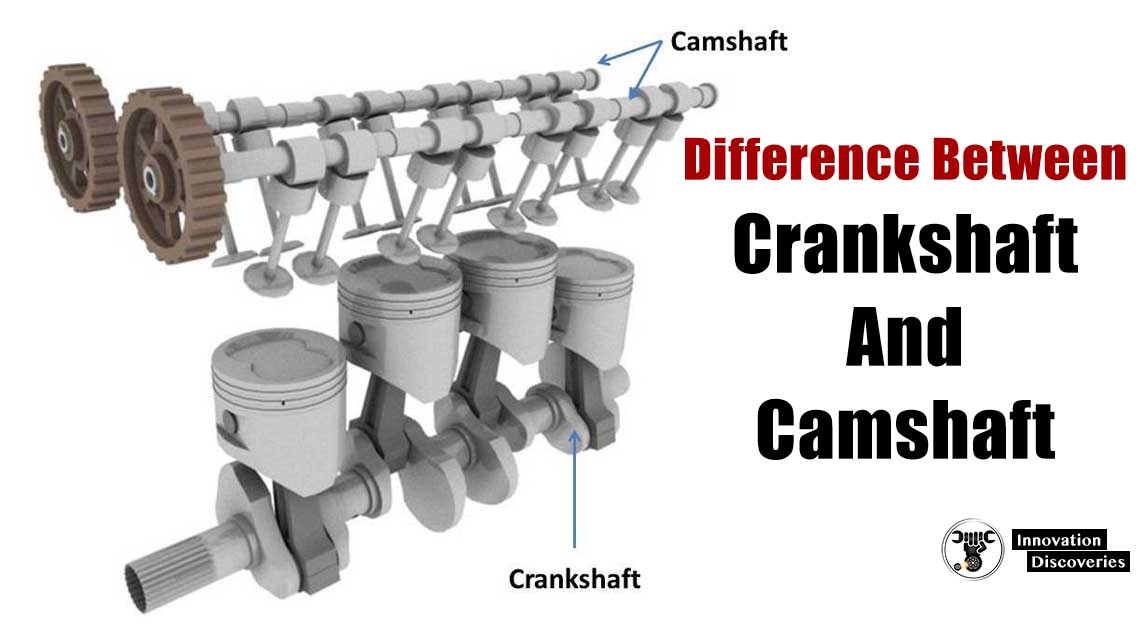

A shaft is a rotating member which is subjected to bending moments and twisting moments and sometimes to axial loads.

It is acted upon by combined bending, torsional and axial stress. And it is desired to transfer motion or power.

And it usually comes with a circular cross-section. You can also see it in a cross-section other than circular.

It may come with varying diameters and lengths. you can find different elements like gears, pulleys, sprockets, etc. on it.

The shaft is also differentiated as the drive or driven shaft according to its position in a machine.

Idler shaft is simply a shaft with gearwheels used as spacing or to change the direction of rotation, It is also used to get the required tension in a chain or belts between two sprockets or pulleys.

DOWNLOAD: BASIC SHAFT ALIGNMENT WORKBOOK

- CONSTRUCTION OF PROPELLER SHAFT

- 3 CAUSES OF DRIVE SHAFT NOISE (WHEN TURNING, BRAKING OR IN REVERSE)

- 6 MOST COMMON CRANKSHAFT POSITION SENSOR SYMPTOMS

- WHAT IS DRIVESHAFT? WORKING OF DRIVESHAFT

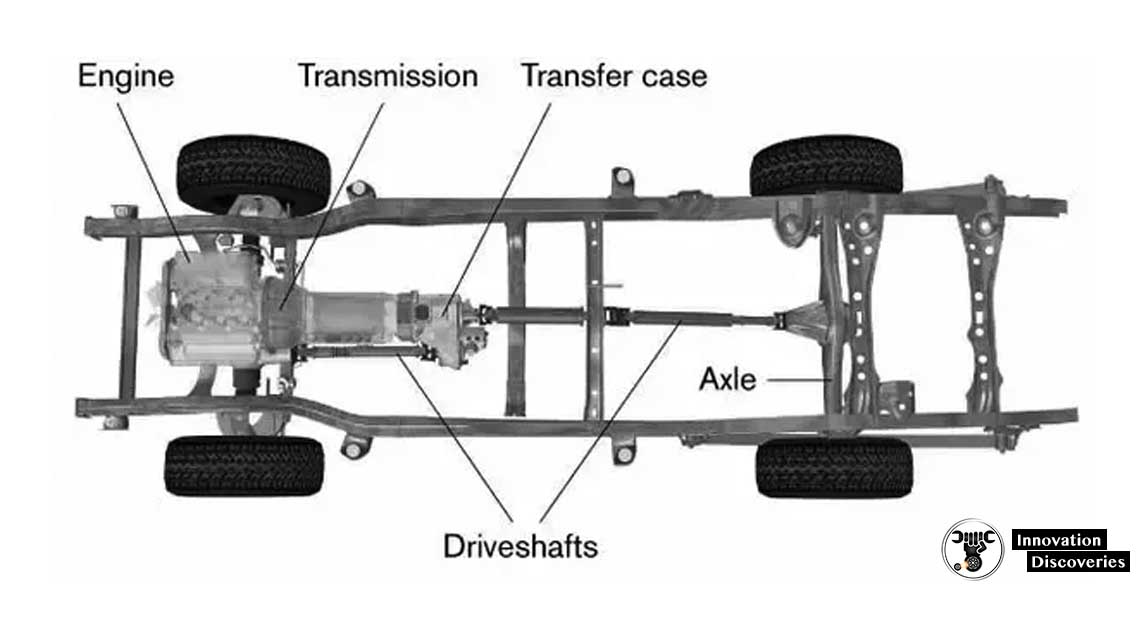

AXLE

An axle is designed and manufactured in such a way that it can only take bending loads. And it is not used for torque transmission.

It is generally a static part. It is attached to the output as a joint.

In the automobile industry, it is commonly utilized as the center of rotation.

Axles may or may not be rotating but, they only transfer bending moments only. It is used to support two or more rotating members.

Questions & answers

Q. What’s the difference between a shaft and an axle?

- A. There are several schools of thought on this. One states that “true” axles are merely static rods that support rotating members, and only shafts transmit power and motion. Another defines an axle as any wheel support, whether or not it transmits power and motion, while a shaft accepts and drives gears, pulleys, sprockets, and other rotary power elements.

Q. What support do bearings offer an axle or shaft?

- A. Bearing end conditions are a complex and crucial factor in shaft behavior. Bearings that allow the shaft to pivot under a transverse load make for easier shaft bending and a lower lateral natural frequency. From another standpoint, soft or loose end supports allow radial movement of the shaft centerline, so the shaft can resonate yet remain straight. Prohibiting this radial end movement forces the shaft to flex under resonance, and raises the critical speed.

Q. Can a shaft be pushed safely beyond the first critical speed?

- A. Yes. In some machinery, shafts are designed to accelerate quickly past one or more resonance frequencies to reach operating speed. Significant bearing damping is helpful when moving through these critical speeds. Above the first critical speed, rigid shafts sometimes become flexible.

HOW MANY AXLES DOES A CAR HAVE? KNOWN IT HERE

- THE DIFFERENCES BETWEEN SEMI-FLOATING VS FULL FLOATING AXLES

- CHECKING THE REAR AXLE FOR LEAKS AND CHANGING THE OIL

Visit Forum

Visit Our Friendly Website

One Comment