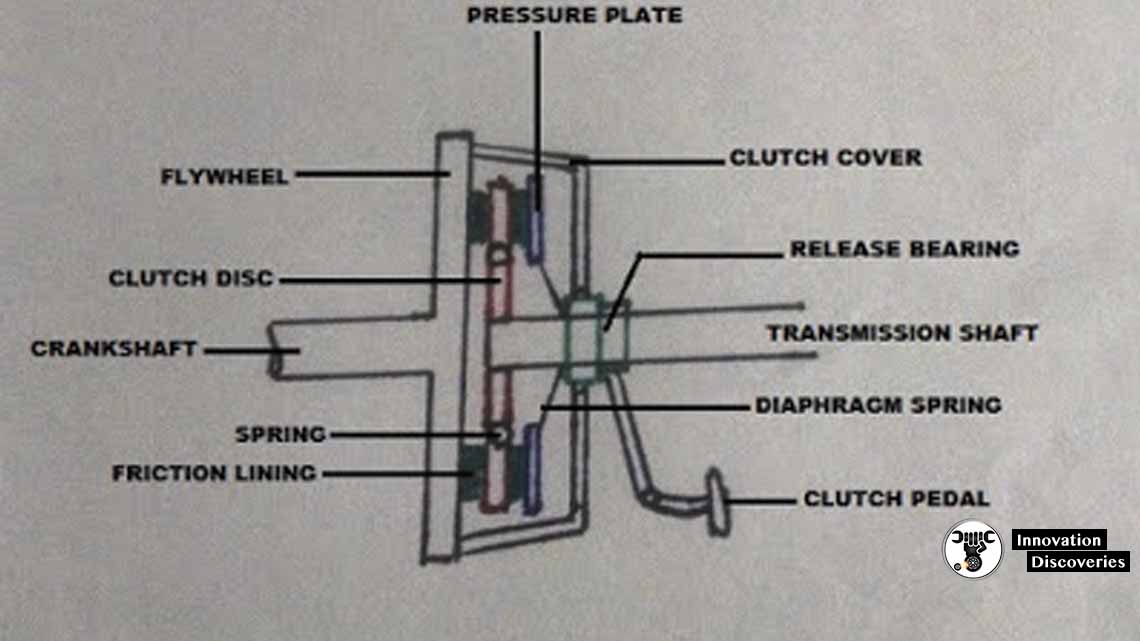

A vast majority of cars rely on single plate friction clutches which will be explained in this article. One of its components is the flywheel which is connected to the engine crankshaft. The flywheel is coated with a friction surface on one side.

A clutch disc equipped with 2 frictional surfaces is brought in contact with the flywheel. In general, if the friction surface of the flywheel comes in contact with the friction surface of the clutch disc,

The clutch disc will start rotating along with the flywheel.

Clutch Disc:

The clutch disc is made of several parts such as:

- A hub that is fixed to the clutch disc. The hub has internal teeth that are engaged with the transmission shaft or driven shaft.

- The friction material on both sides. Friction materials today are usually made of ceramics rather than asbestos to increase the coefficient of friction.

- A cover plate is provided to cover the hub and the disc.

- A set of 4 springs are provided to dampen the vibrations and for smoother operation when the clutch is engaged with the flywheel.

The wheels of a vehicle will only rotate if the clutch disc is in contact with the flywheel.

Also, read: How a car clutch works

Pressure Plate:

A pressure plate is imperative for engaging and disengaging the clutch disc with the flywheel. The clutch disc is sandwiched between the flywheel and the pressure plate. A diaphragm spring is provided in the pressure plate to allow for a flexible movement of the plate. A clutch release bearing is provided in front of the spring to facilitate the

Compression and release of the spring. The clutch pedal is connected to the release bearing.

Clutch Cover:

A clutch cover is used to cover the entire clutch assembly. It is riveted to the flywheel. Therefore, as the flywheel rotates, the clutch cover also rotates at the same speed

Irrespective of the engagement and disengagement of the clutch disc.

Working of Single Plate Clutch:

When the clutch pedal is pressed, the release bearing moves in a direction towards the flywheel. The inner portion of the diaphragm spring moves in towards the clutch disc,

Whereas the outer portion of the spring moves in the opposite direction. As a result, the pressure plate which is connected to the outer portion of the

Diaphragm spring moves away from the clutch disc. Therefore, the clutch disc is disengaged from the flywheel. The power from the engine now cannot be transferred to the gearbox. The driver utilizes this time to shift gears from bottom to top gear or vice-versa.

When the clutch pedal is released,

The force on the diaphragm spring is also released and the pressure plate now pressed against the clutch disc. Consequently, the clutch disc is engaged with the flywheel.

Don’t miss

3 Comments