Coolant additives play a crucial role in maintaining the optimal performance and longevity of diesel engines. Diesel engines generate high levels of heat, which can lead to internal engine corrosion and overheating if not properly managed.

In this article, we will explore the symptoms of a failing coolant additive for diesel engines and provide valuable repair advice to address potential issues.

Symptoms of a Bad or Failing Coolant Additive for Diesel Engines:

1. Internal Engine Corrosion:

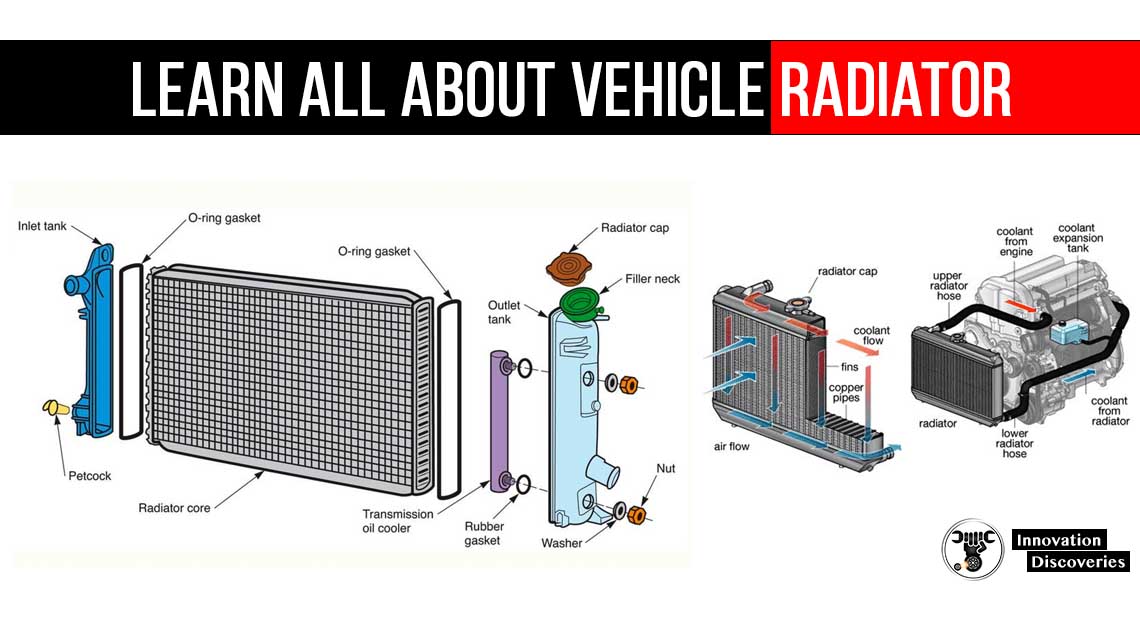

A vital function of a coolant additive is to prevent corrosion within the engine’s cooling system. Over time, coolant can become contaminated with impurities and lose its effectiveness. When the coolant additive fails to inhibit corrosion, it can result in the following symptoms:

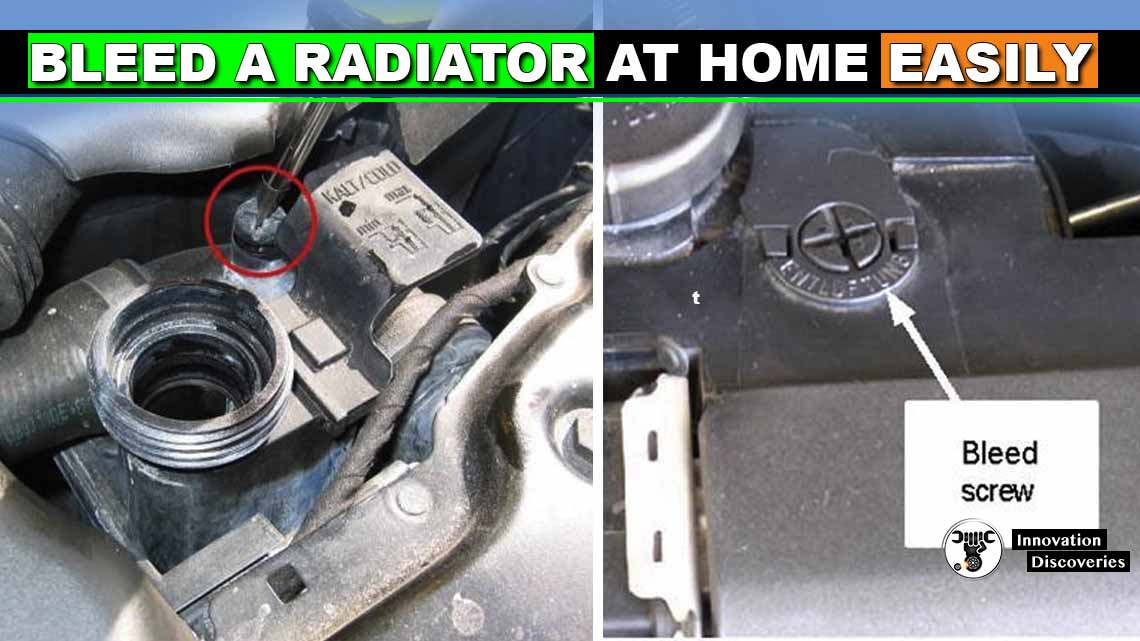

- Coolant leakage: Corrosion can cause tiny leaks in the cooling system, leading to a loss of coolant. Look for signs of coolant puddles under the vehicle or a gradual decrease in coolant levels.

- Rust-colored coolant: If the coolant appears rusty or discolored, it is an indication of internal corrosion. This should be addressed promptly to prevent further damage.

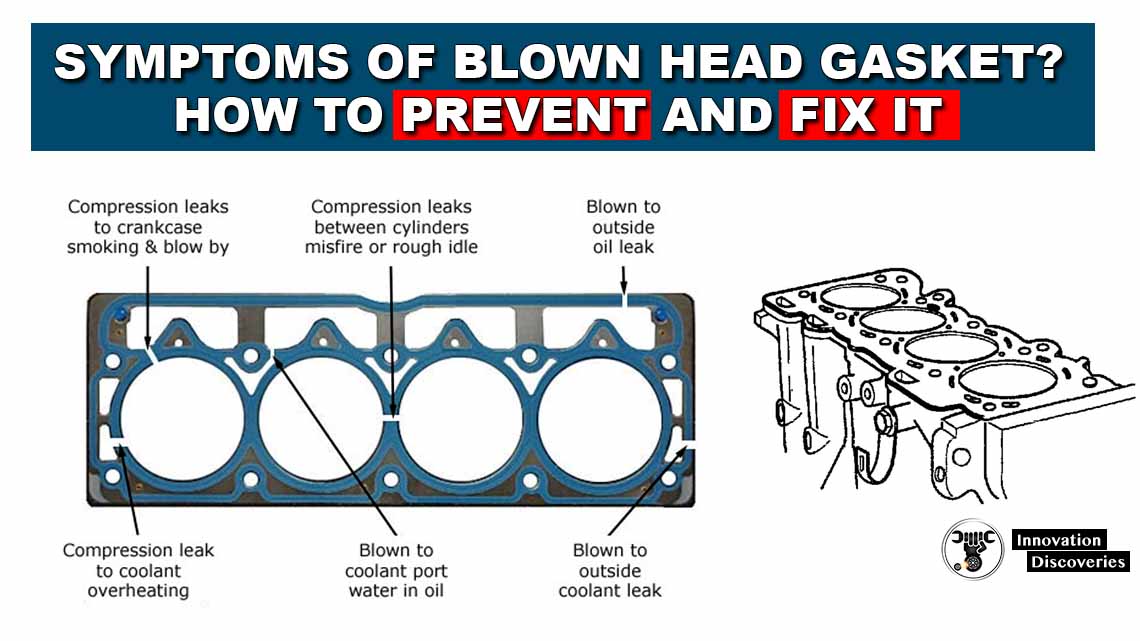

- Damaged gaskets and seals: Corrosion can erode gaskets and seals within the cooling system, leading to coolant leaks and potential engine damage.

2. Engine Overheating:

Coolant additives are specifically formulated to manage heat and prevent engines from overheating. When the coolant additive fails to fulfill its purpose, the engine may experience overheating, which can result in severe damage. Look out for the following signs:

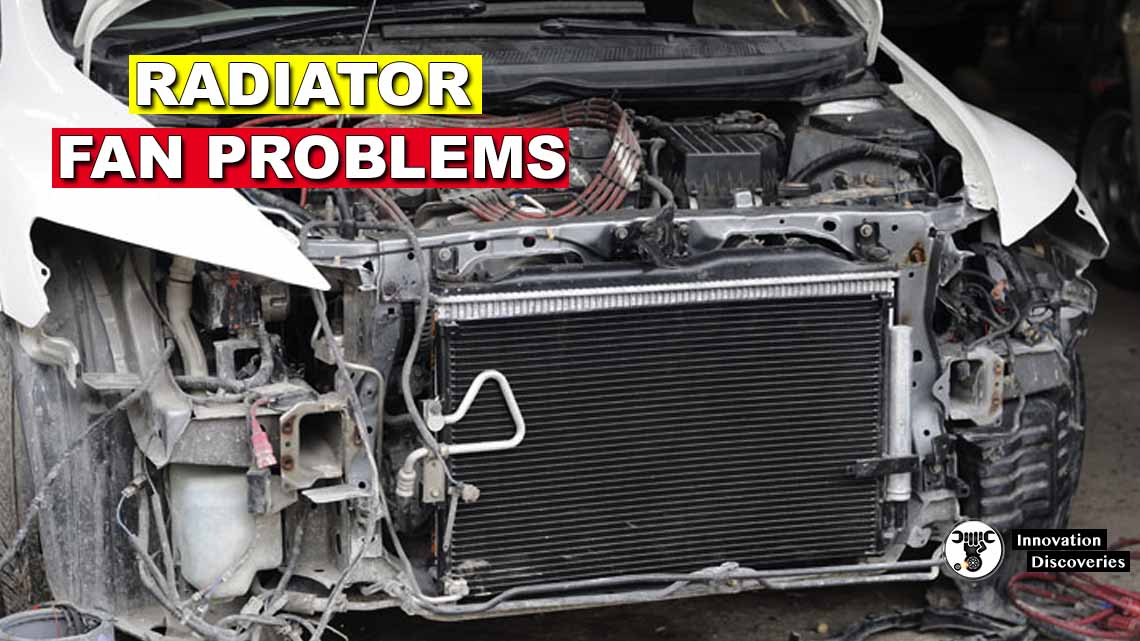

- Rising temperature gauge: If the engine temperature gauge consistently indicates high readings or quickly rises to the red zone, it signifies an overheating issue.

- Steam or smoke from the engine bay: Overheating can cause coolant to boil, resulting in steam or smoke coming from the engine compartment. This requires immediate attention to prevent further damage.

- HOW TO CHOOSE THE RIGHT GASKETS

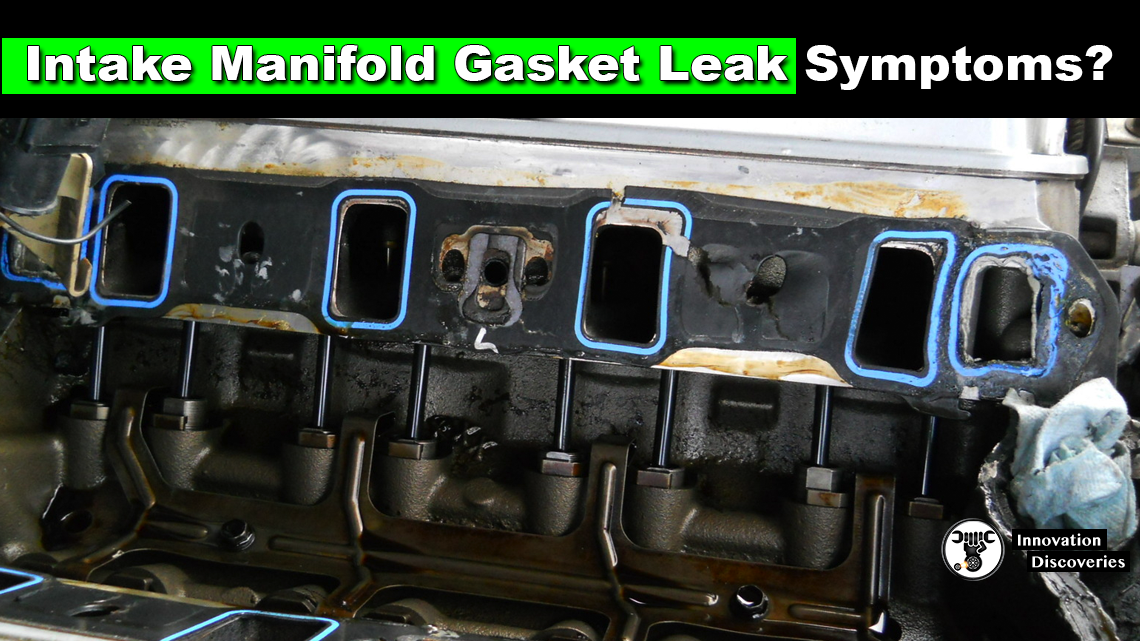

- WHAT ARE THE INTAKE MANIFOLD GASKET LEAK SYMPTOMS?

- DETECTING HEAD GASKET ISSUES AND THE SOLUTION

- SHOULD I GET A TRANSMISSION FLUSH? REASONS TO GET A TRANSMISSION FLUSH

Coolant Additive for Diesel Engine Related Repair Advice:

1. Regular Coolant System Flush:

To maintain the effectiveness of the coolant additive, it is crucial to perform regular coolant system flushes as recommended by the manufacturer. Flushing the system helps remove any contaminants, sludge, or old coolant, allowing for fresh coolant and additive to be added.

2. Choose the Right Coolant Additive:

Not all coolant additives are created equal, and it is essential to select the appropriate additive specifically formulated for diesel engines. Consult the vehicle’s owner’s manual or seek guidance from a trusted mechanic to identify the best coolant additive for your diesel engine.

3. Follow Manufacturer Recommendations:

Always follow the manufacturer’s recommendations regarding the type of coolant additive, concentration levels, and maintenance intervals. Overdosing or underdosing the additive can lead to ineffective performance or potential engine damage.

4. Regular Inspection of Cooling System Components:

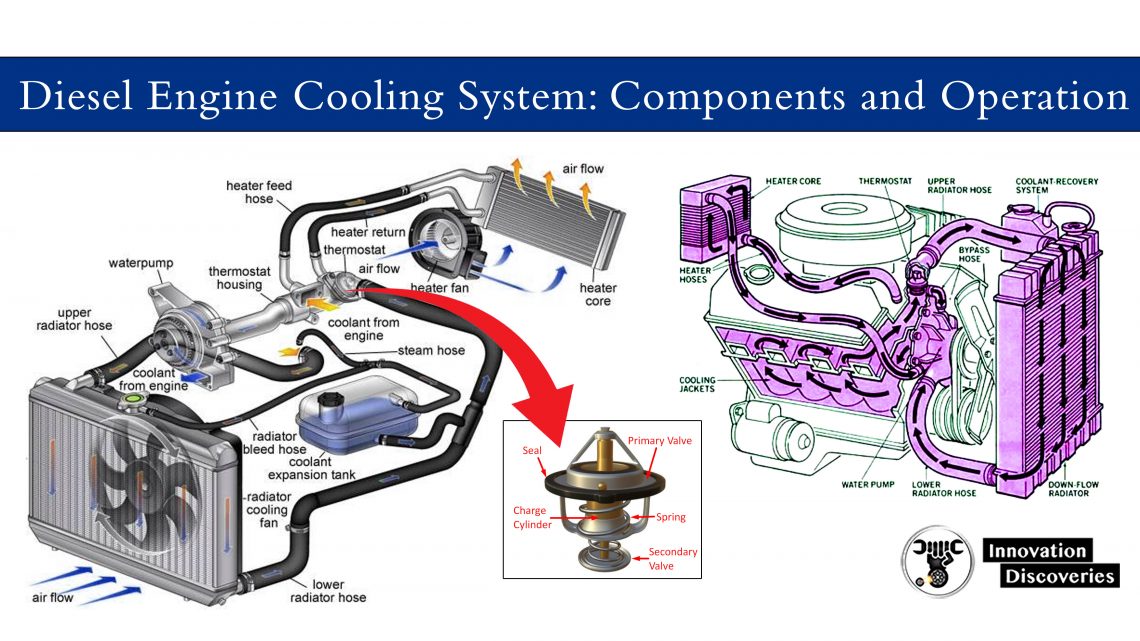

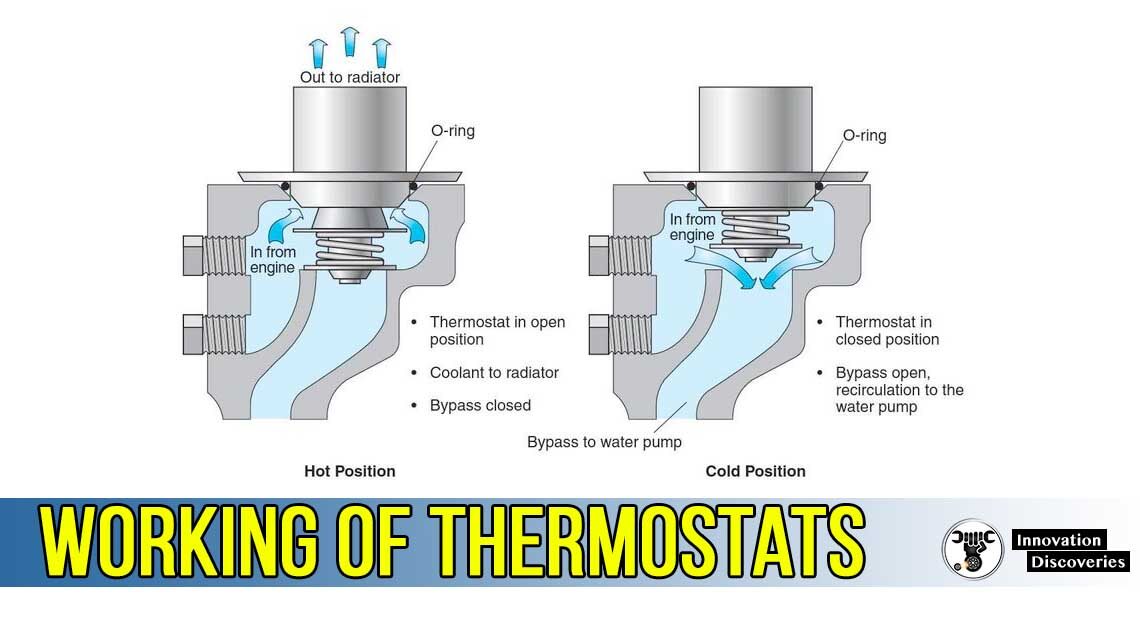

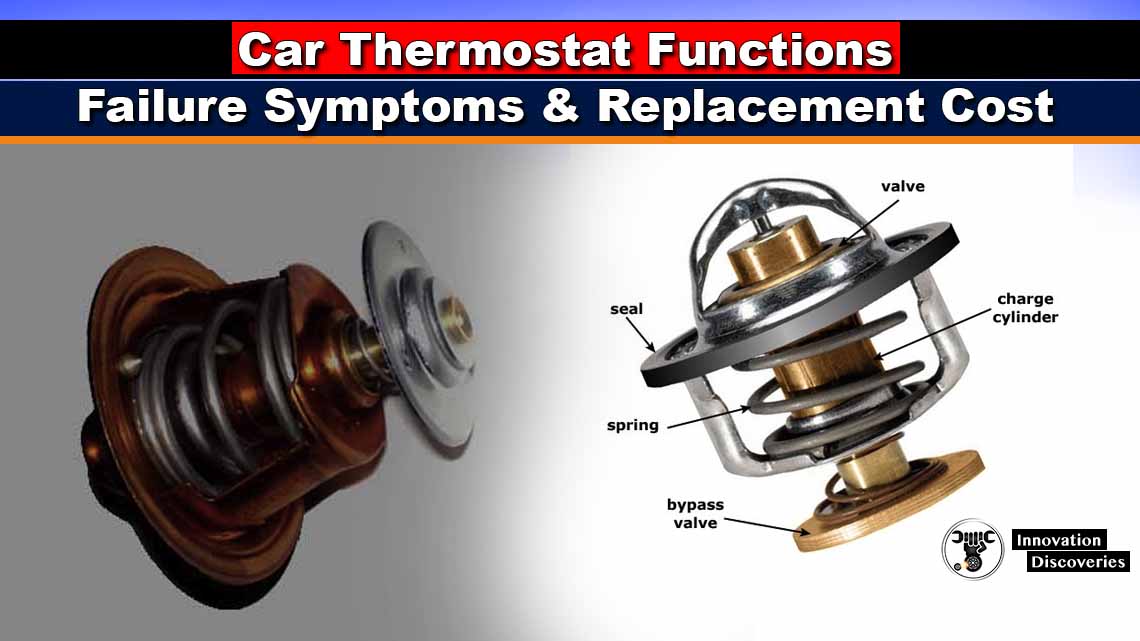

Regularly inspect the cooling system components, such as hoses, belts, radiator, and thermostat, for signs of wear or damage. Replace any worn-out parts promptly to ensure proper coolant circulation and prevent potential coolant additive failures.

Conclusion:

Maintaining a healthy cooling system in diesel engines is crucial for optimal performance and longevity. By understanding the symptoms of a failing coolant additive, such as internal engine corrosion and engine overheating, and following the repair advice outlined in this article, diesel engine owners can ensure the proper functioning of their vehicles and prevent costly repairs in the long run.

Remember, regular maintenance and using the right coolant additive are key to keeping your diesel engine running smoothly.

Visit Forum

Visit Our Friendly Website