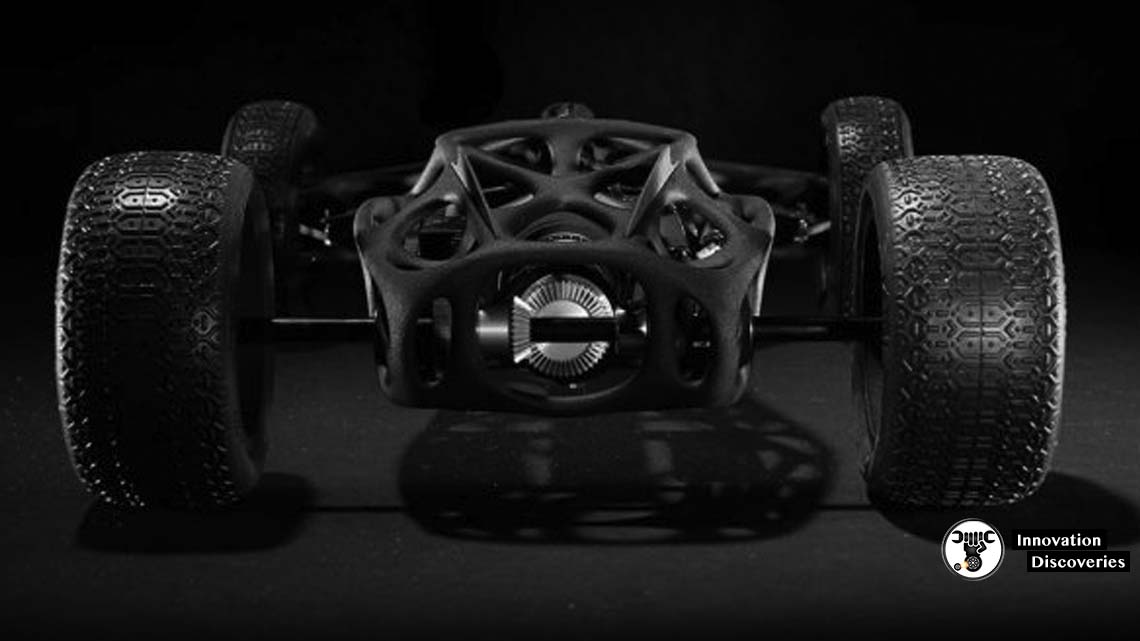

Almost all of us played with cars powered with a rubber band when we were young. We bet, none of them was as cool as Cirin. Cirin is a mid-1950s Formula 1 car based mini racecar, featuring state-of-the-art construction and design.

It is powered by 16 ft (5 m) of looped elastic material that can

Make it travel for 500 ft (152 m) at an amazing speed of 30 mph (48 km/h).

Max Greenberg, Sameer Yeleswarapu,

And Ian Cullimore from the Art Center College of Design in Pasadena,

California has designed this amazing mini racer for their school’s annual event formula E Race.

It was an international event where various teams participated to present

Their amazing rubber band-powered miniature cars.

Who won the race? We are pretty sure that you have already guessed the name!

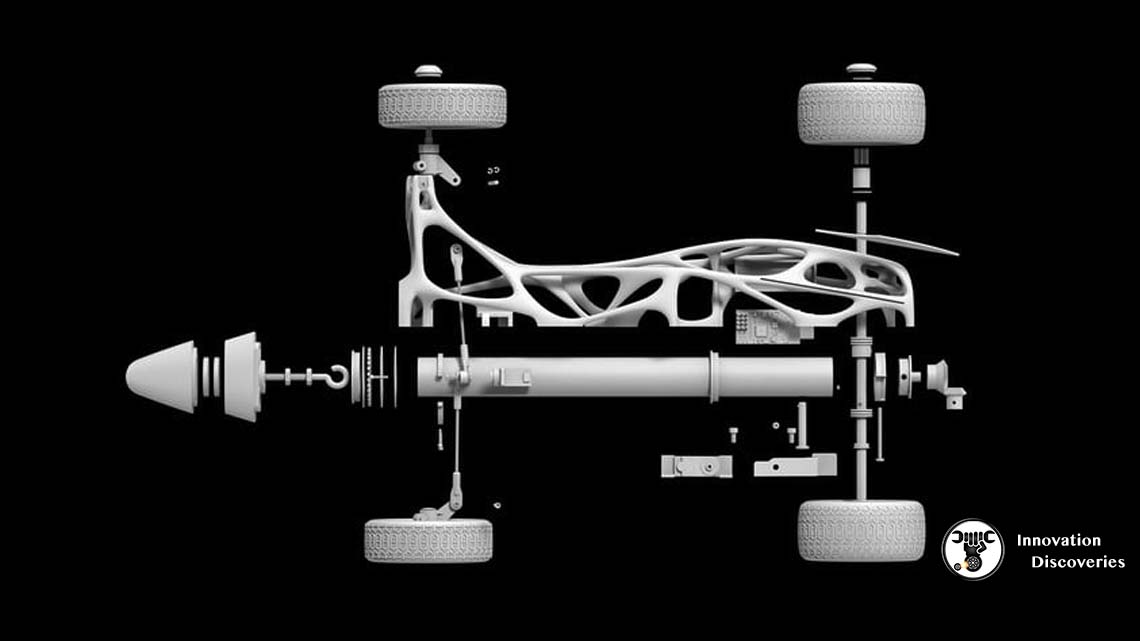

Ciren was completely designed using a mechanical software called,

SolidWorks after simulating several prototypes.

The fabrication of the final model was done using

3D printing technology by a company called SolidConcepts.

They used laser sintering to melt successive layers of nylon powder to yield the final shape.

Ciren was completely designed using a mechanical software called

SolidWorks after simulating several prototypes.

The fabrication of the final model was done using,

3D printing technology by a company called SolidConcepts.

They used laser sintering to melt successive layers of nylon

Powder to yield the final shape.

The structure is known for its high strength-to-weight ratio.

Thus, this car can withstand the rubber band’s high torsional stresses. Besides, it is made strong and robust by the lack of any big fastener.

This loop runs within a carbon fiber tube and the two eye bolts.

The first bolt is located at the car’s nose,

And the other in the geared drive mechanism at the rear axle.

A second servo motor is used to steer the system,

Which is controlled by radio remote control.

Cirin’s cost is reported to be a whopping US$500,

And this is without the 3D printing donation by SolidConcepts.