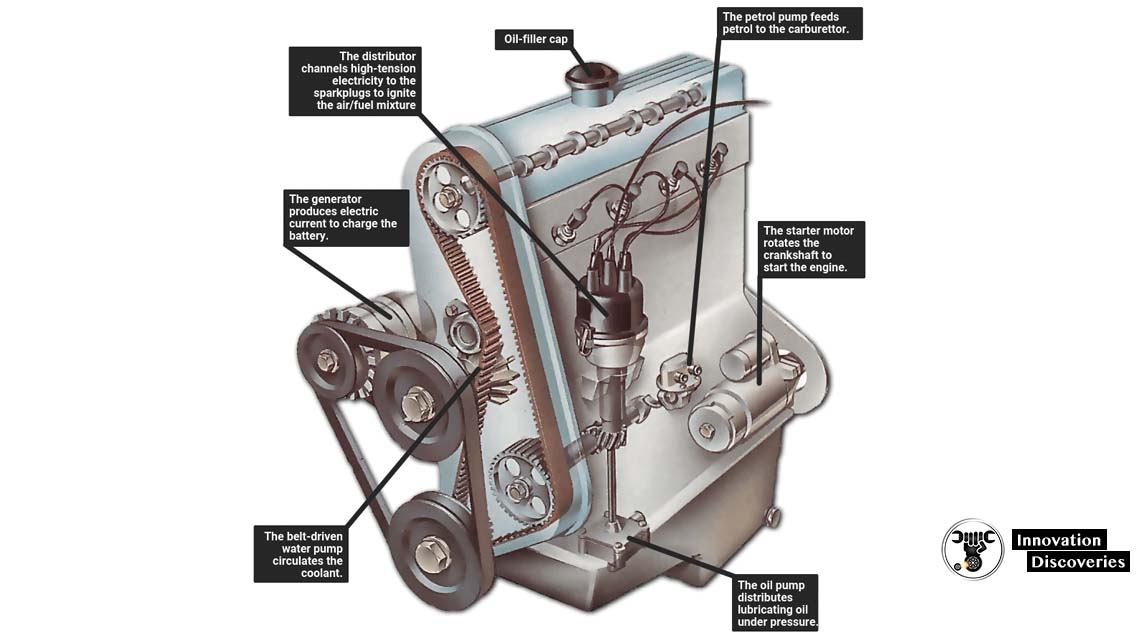

The engine is, in many respects, self-sustaining,

It supplies the power that drives a number of ancillary

Subordinate components without which it could not work.

It requires a controlled fuel supply,

A timed electric spark to ignite the air-and-fuel mixture, a means of dispersing heat, and lubrication to reduce friction.

These ancillary functions are carried out mainly by mechanically driven components.

The crankshaft is their main power source,

Through gears and sprockets or pulley-driven chains or belts.

Starting the engine

A powerful electric motor connected directly to the battery is used to,

Rotate the crankshaft at a speed high enough to initiate

The four-stroke cycle and start the engine.

Starting the car, particularly from cold,

Therefore makes the heaviest demand on the battery,

Since the starter motor has first to overcome the inertia of the engine.

There is also a high demand for electrical equipment such as flashers and lights,

So the battery needs constant replenishing in order to maintain

Its charge of about 12 volts.

Charging the battery

Charging is accomplished by a generator a dynamo in earlier cars,

Or an alternator in later ones – driven by the crankshaft.

The generator output is controlled by a charging circuit

Which ensures that the battery receives the correct amount of current

Necessary to keep it fully charged.

Producing the spark

To produce the timed electric spark needed to ignite the fuel mixture,

The low voltage from the battery is boosted to a very high voltage,

About 30,000, by the ignition coil a form of transformer.

The low-tension (LT) voltage passes through a primary winding in the

Coil and then to the contact breaker points in the distributor.

Each time the low-tension-current circuit is interrupted by the

Opening of the contact-breaker points in the distributor,

he electrical surge as the current suddenly collapses induces high-tension (HT)

Voltage in a secondary winding in the coil.

The distributor then feeds the high-tension voltage to each of the spark-plugs in turn at the correct time. Each spark plug has two electrodes at its tip,

With a gap between them.

The high-tension voltage jumps this gap and produces the

Spark that ignites the air and fuel mixture.

Driving the pumps

The petrol pump that feeds the carburetor is either a mechanical one operated by

An off-center disc a sort of circular cam – on the engine carburetor

Or an electric pump remotely mounted, sometimes close to the petrol tank.

In water-cooled cars,

The water pump that circulates water through the cooling passages of the engine

Is belt-driven from a pulley on the crankshaft.

The oil pump that pressurizes oil for engine lubrication works

Directly from the crankshaft or camshaft.

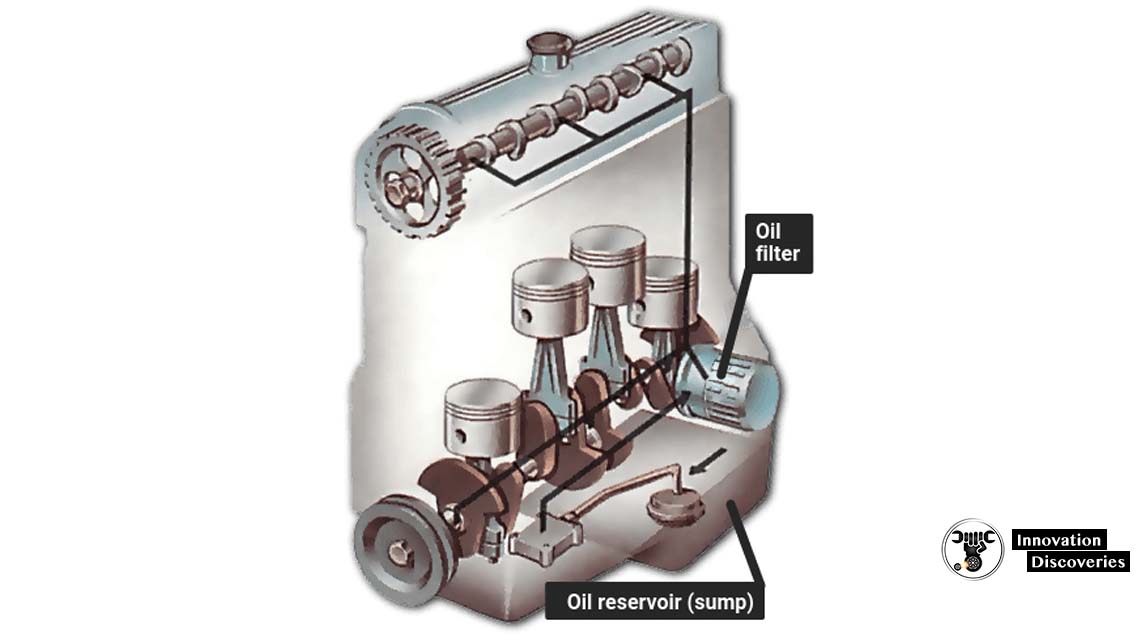

How the engine is lubricated

Friction between moving metal parts in the engine is minimized by a thin film of oil.

Oil from the pump passes through passages in the crankshaft, block, and camshaft bearings.

Stored in a reservoir, called the sump, at the bottom of the engine,

The oil is sucked into the pump,

Which sends it under pressure through various feed pipes and channels to the

Moving parts of the engine and then back to the sump.

The oil is circulated under pressure at a rate of several gallons per minute.

The pressure is controlled in the pump by a relief valve,

When the pressure is excessive,

It leaks some of the oil back to the sump.

Oil forced out of the crankshaft journals is thrown against the cylinder walls.

This is known as ‘splash lubrication’.

Before reaching the engine, the oil passes through a filter attached to the pump,

Which removes sludge and potentially abrasive particles such as

Debris resulting from engine wear.

If the pressure drops – usually through mechanical failure or if there is an oil deficiency,

The moving parts of the engine wear rapidly and eventually seize

Types of oil pump

Gear-type oil pump

In a gear-type oil pump, oil pressure is created at the point where the gears mesh.

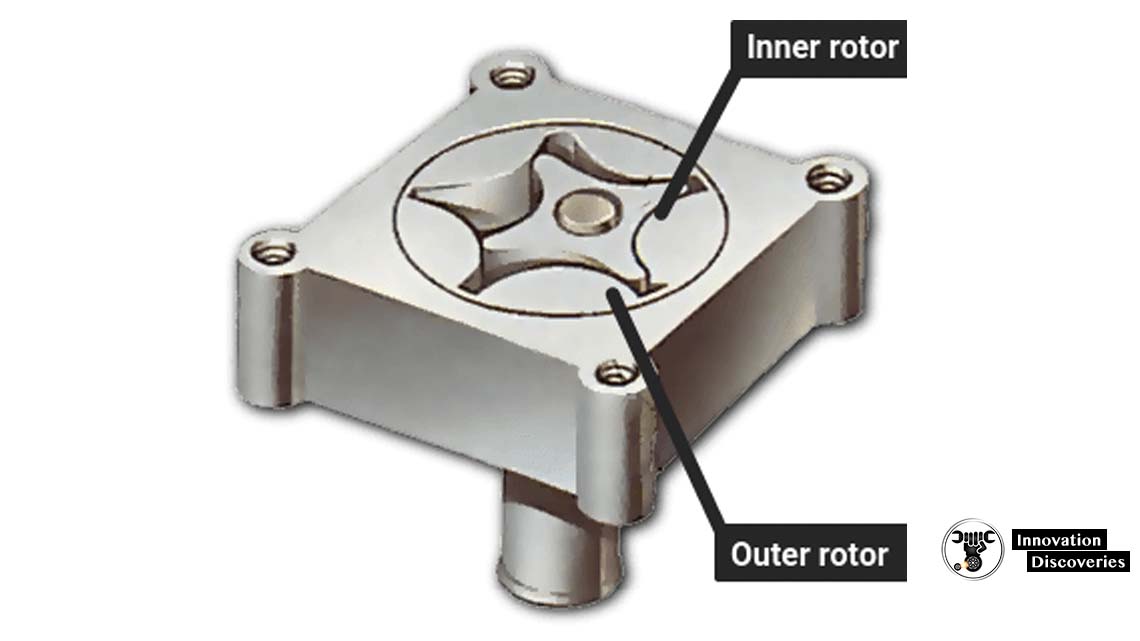

Rotor-type oil pump

Pressure in a multi-lobe pump is created between the inner and outer rotors.

How the oil is pumped

There are two basic types of oil pump a rotor type and a gear type.

The rotor pump has two multi-lobed rotors an inner one and an outer one,

Revolving on different axes. The gear type has two adjacent meshing gears.

The pump may be mounted internally or externally.

Oil sucked from the sump is pressurized as it passes through the

Decreasing gap between the rotor lobes or meshing gears.

The commonest filter element used to trap the sludge and debris

Hat collects in the sump is made from resin-impregnated, pleated paper.

Also, read

What is Automobile Injector and its Types

2 Comments