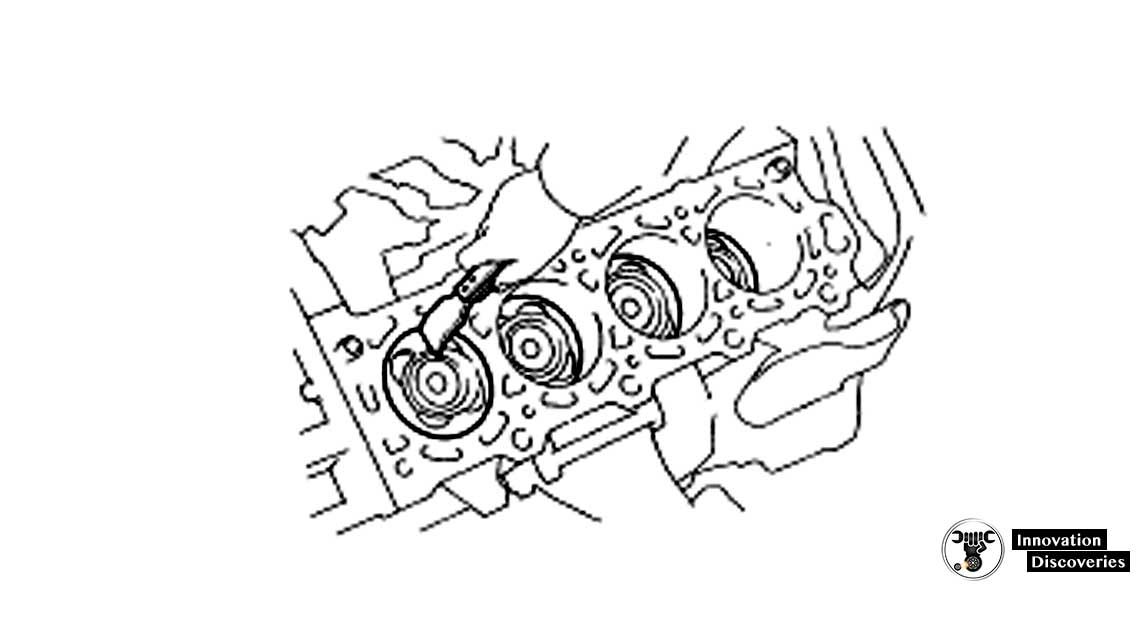

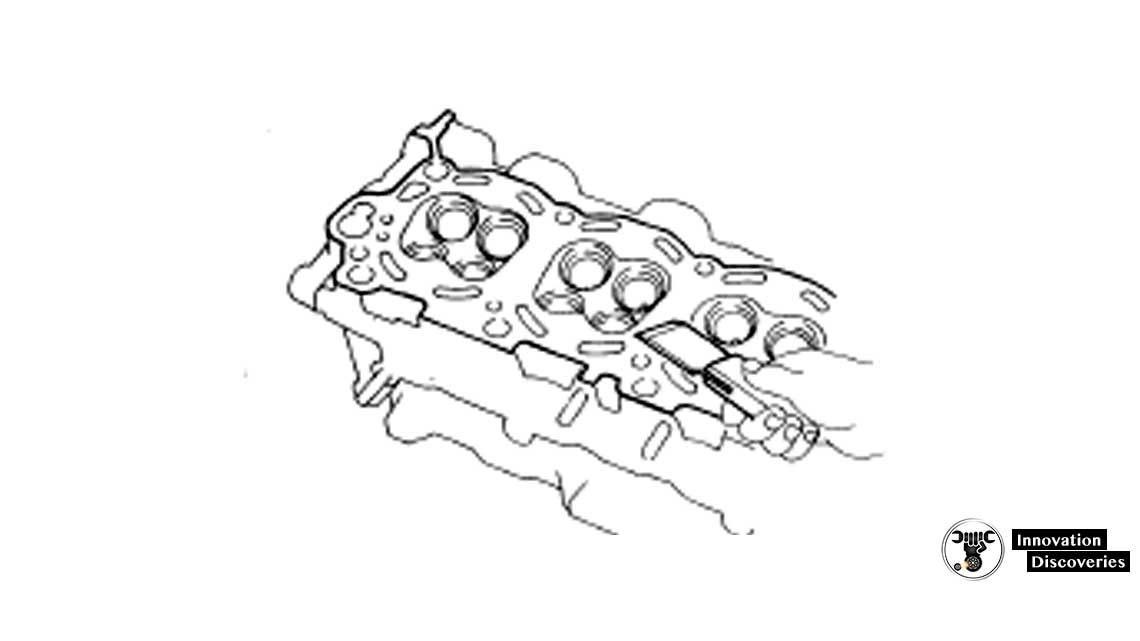

1. CLEAN TOP SURFACES OF PISTONS AND CYLINDER BLOCK

(a) Turn the crankshaft, and bring each piston to top dead center (TDC). Using a gasket scraper, remove all the carbon from the piston top surface.

(b) Using a gasket scraper, remove all the gasket material from the cylinder block surface.

(c) Using compressed air, blow carbon and oil from the bolt holes.

CAUTION: Protect your eyes when using high pressure compressed air.

Read More:

6 MOST COMMON CRANKSHAFT POSITION SENSOR SYMPTOMS

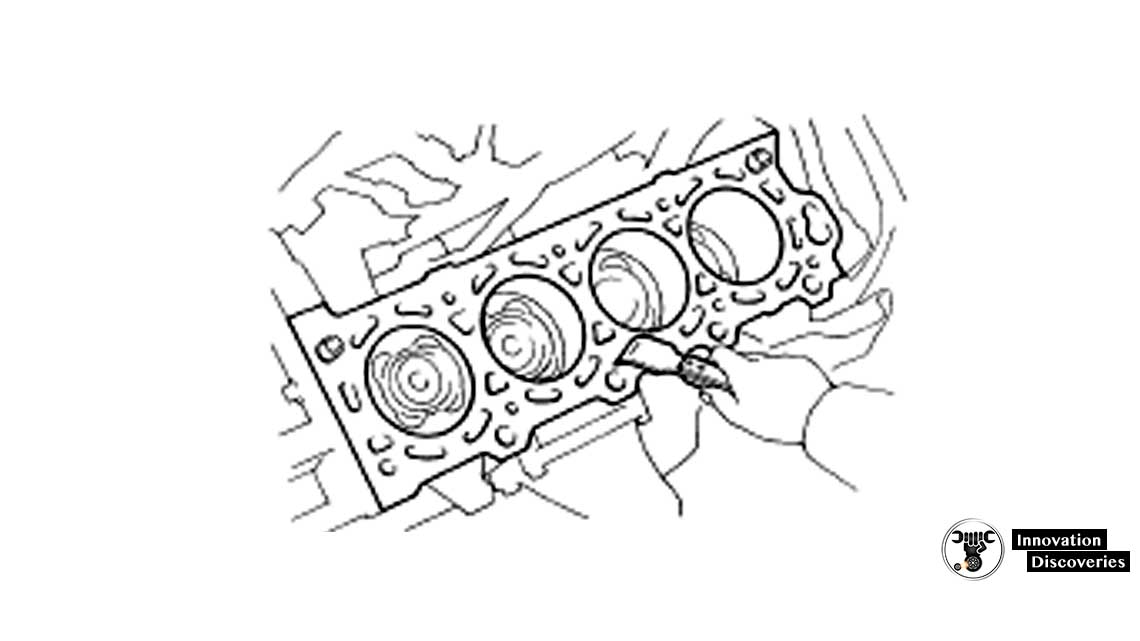

2. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all the gasket material from the cylinder block contact surface.

NOTICE: Be careful not to scratch the cylinder block contact surface.

3. CLEAN COMBUSTION CHAMBERS

Using a wire brush, remove all the carbon from the combustion chambers.

NOTICE: Be careful not to scratch the cylinder block contact surface.

4. CLEAN VALVE GUIDE BUSHINGS

Using a valve guide bushing brush and solvent, clean all the guide bushings.

5. CLEAN CYLINDER HEAD

Using a soft brush and solvent, thoroughly clean the cylinder head.

6. INSPECT FOR FLATNESS

Using a precision straight edge and a feeler gauge, measure the surfaces contacting the cylinder block and the manifolds for a warp.

Maximum warpage: 0.10 mm (0.0039 in.)

If the warp is greater than maximum, replace the cylinder head.

7. INSPECT FOR CRACKS

Using a dye penetrate, check the combustion chamber, the intake ports, the exhaust ports and the cylinder head surface for cracks.

If there is a crack, replace the cylinder head.

8. CLEAN VALVES

(a) Using a gasket scraper, chip off any carbon from the valve head.

(b) Using a wire brush, thoroughly clean the valve.

9. INSPECT VALVE STEMS AND GUIDE BUSHINGS

(a) Using a calliper gauge, measure the inside diameter of the guide bushing.

Bushing inside diameter: 5.510 – 5.530 mm (0.2169 – 0.2177 in.)

(b) Using a micrometre, measure the diameter of the valve stem.

Valve stem diameter:

Intake 5.470 – 5.485 mm (0.2154 – 0.2159 in.)

Exhaust 5.465 – 5.480 mm (0.2152 – 0.2157 in.)

(c) Subtract the valve stem diameter measurement from the guide bushing inside diameter measurement.

Standard oil clearance:

Intake 0.025 – 0.060 mm (0.0010 – 0.0024 in.)

Exhaust 0.030 – 0.065 mm (0.0012 – 0.0026 in.)

Maximum oil clearance:

Intake 0.08 mm (0.0031 in.)

Exhaust 0.10 mm (0.0039 in.)

If the clearance is greater than the maximum, replace the valve and the guide bushing. ( EM-55 )

10. INSPECT AND GRIND VALVES

(a) Grind the valve enough to remove pits and carbon.

(b) Check that the valve is ground to the correct valve face angle.

Valve face angle: 44.5

(c) Check the valve head margin thickness.

Standard margin thickness: IN 1.25 mm (0.049 in.)

EX 1.40 mm (0.055 in.)

Minimum margin thickness: 0.5 mm (0.020 in.)

If the margin thickness is less than the minimum, replace the valve.

(d) Check the valve overall length.

Standard overall length: Intake: 95.05 mm (3.7421 in.) Exhaust: 95.10 mm (3.7441 in.)

Minimum overall length: Intake: 94.55 mm (3.7224 in.) Exhaust: 94.60 mm (3.7244 in.)

If the overall length is less than the minimum, replace the valve.

(e) Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

NOTICE: Do not grind off to below the minimum.

Read More:

11. INSPECT AND CLEAN VALVE SEATS

(a) Using a 45 carbide cutter, resurface the valve seats. Remove just enough metal to clean the seats.

(b) Check the valve seating position.

Apply a light coat of Prussian blue (or white lead) to the valve face. Lightly press the valve against the seat. Do not rotate the valve.

(c) Check the valve face and seat for the following:

- If blue appears 360 around the face, the valve is concentric. If not, replace the valve.

- If blue appears 360 around the valve seat, the guide and face are concentric. If not, resurface the seat.

- Check that the seat contact is in the middle of the valve face with the following width:

1.0 – 1.4 mm (0.039 – 0.055 in.)

If not, correct the valve seats as follows:

- If the seating is too high on the valve face, use 30 and 45 cutters to correct the seat.

- If the seating is too low on the valve face, use 60 and 45 cutters to correct the seat.

(d) Hand-lap the valve and valve seat with an abrasive compound.

(e) After hand-lapping, clean the valve and valve seat.

12. INSPECT VALVE SPRINGS

(a) Using a steel square, measure the deviation of the valve spring.

Maximum deviation: 2.0 mm (0.079 in.)

If the deviation is greater than the maximum, replace the valve spring.

(b) Using vernier callipers, measure the free length of the valve spring.

Free length: 54.1 mm (2.130 in.)

If the free length is not as specified, replace the valve spring.

(c) Using a spring tester, measure the tension of the valve spring at the installed length.

Installed tension: 204 – 226 N (20.8 – 23.0 kgf, 45.9 – 50.7 lbf) at 35.0 mm (1.378 in.)

If the installed tension is not as specified, replace the valve spring.

13. INSPECT CAMSHAFT FOR RUNOUT

(a) Place the camshaft on V-blocks.

(b) Using a dial indicator, measure the circle runout at the center journal.

Maximum circle runout: 0.08 mm (0.0031 in.)

If the circle runout is greater than the maximum, replace the camshaft

14. INSPECT CAM LOBES

Using a micrometre, measure the cam lobe height.

Standard cam lobe height:

Intake: 41.94 – 42.04 mm (1.6512 – 1.6551 in.)

Exhaust: 41.96 – 42.06 mm (1.6520 – 1.6559 in.)

Minimum cam lobe height:

Intake: 41.79 mm (1.6453 in.)

Exhaust: 41.81 mm (1.6461 in.)

If the cam lobe height is less than the minimum, replace the camshaft.

15. INSPECT CAMSHAFT JOURNALS

Using a micrometre, measure the journal diameter.

Journal diameter: 26.954 – 26.970 mm (1.0612 – 1.0618 in.)

If the journal diameter is not as specified, check the oil clearance.

16. INSPECT CAMSHAFT GEAR SPRING

Using vernier callipers, measure the free distance between the spring ends.

Free distance: 18.2 – 18.8 mm (0.712 – 0.740 in.)

If the free distance is not as specified, replace the gear spring.

17. INSPECT CAMSHAFT BEARINGS

Check that bearing for flaking and scoring.

If the bearings are damaged, replace the bearing caps and cylinder head as a set.

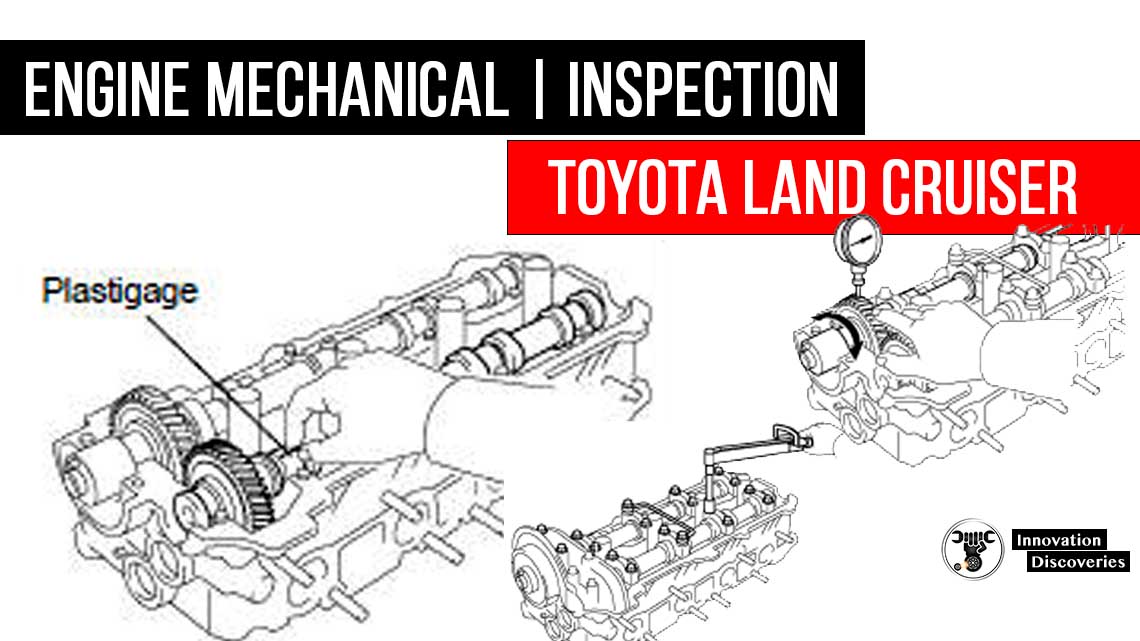

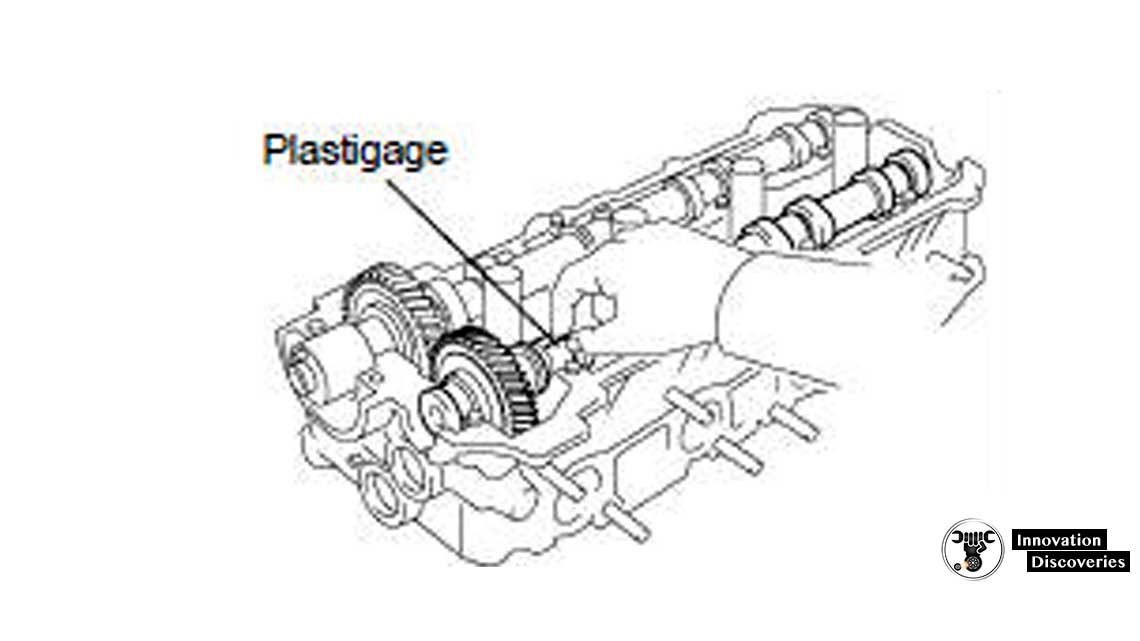

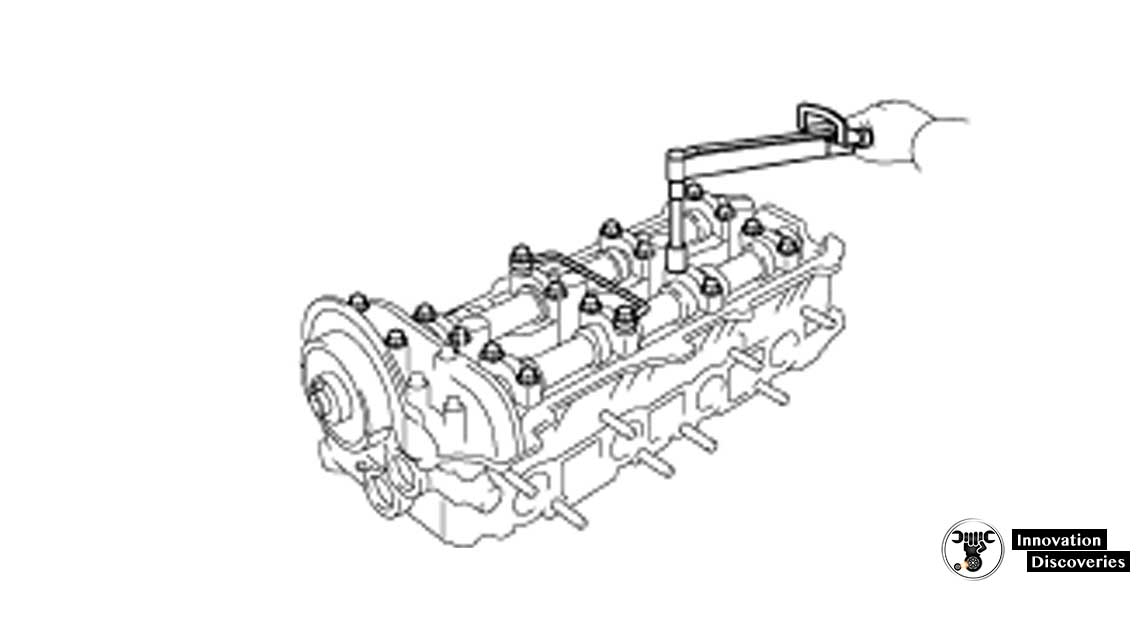

18. INSPECT CAMSHAFT JOURNAL OIL CLEARANCE

(a) Clean the bearing caps and the camshaft journals.

(b) Place the camshafts on the cylinder head.

(c) Lay a strip of plastigage across each of the camshaft journals.

(d) Install the bearing caps.

( EM-59 )

Torque: 16 N·m (160 kgf·cm, 12 ft·lbf)

NOTICE: Do not turn the camshaft.

(e) Remove the bearing caps.

(f) Measure the Plastigage at its widest point.

Maximum oil clearance: 0.10 mm (0.0039 in.)

If the oil clearance is greater than the maximum, replace the camshaft. If necessary, replace the bearing caps and cylinder head as a set.

(g) Completely remove the plastinate.

(h) Remove the camshafts.

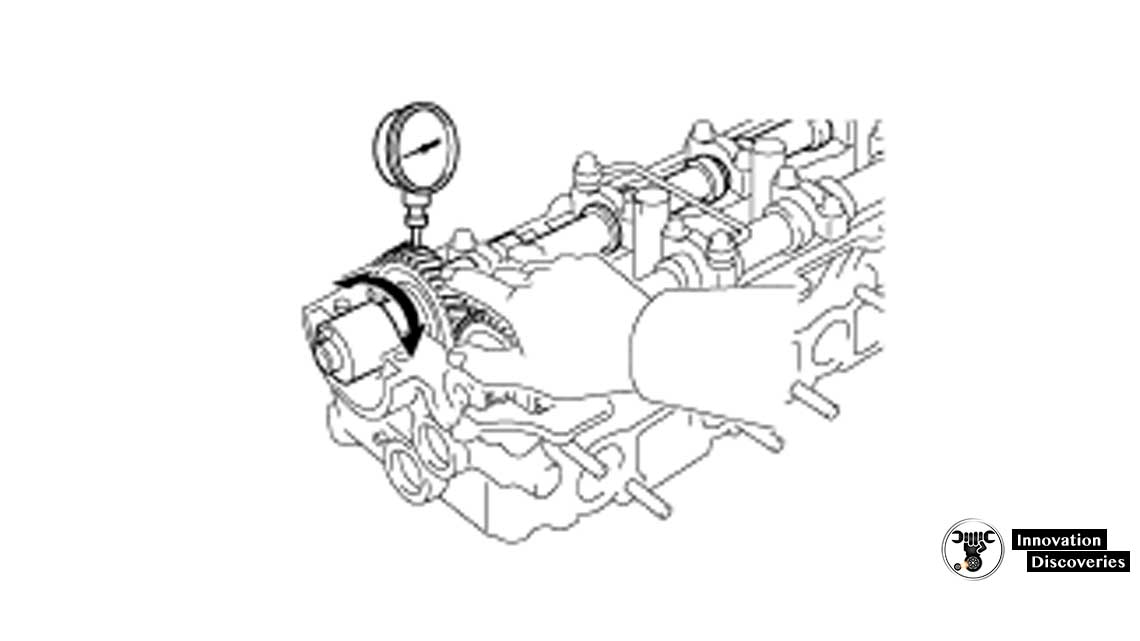

19. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Install the camshaft.

( EM-59 )

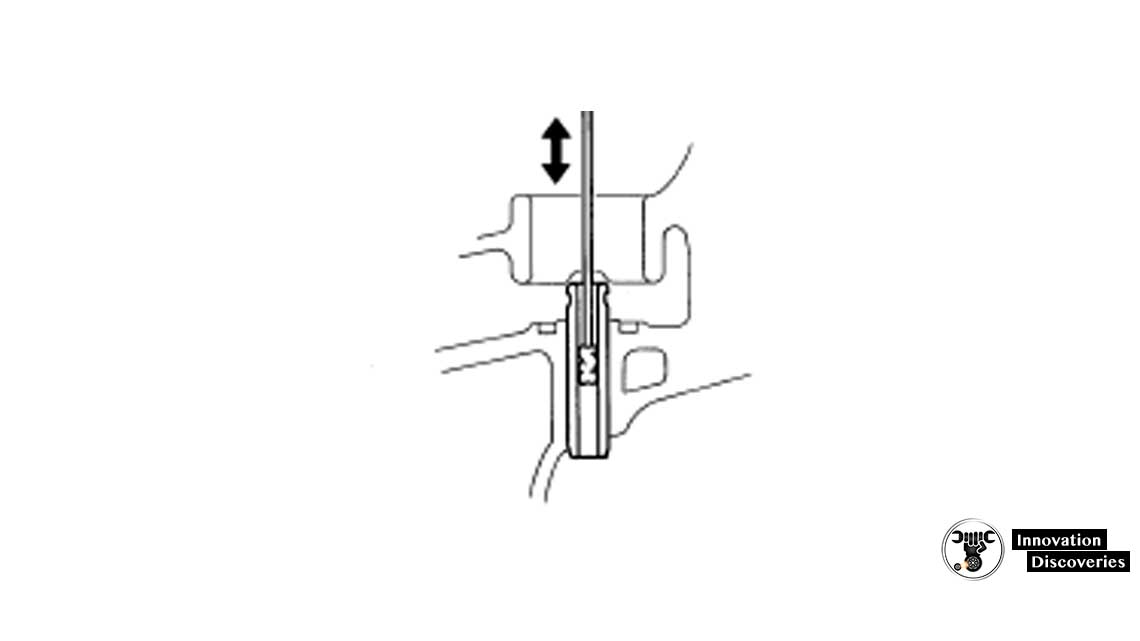

(b) Using a dial indicator, measure the thrust clearance as moving the camshaft back and forth.

Standard thrust clearance:

Intake 0.040 – 0.090 mm (0.0016 – 0.0035 in.)

Exhaust 0.040 – 0.085 mm (0.0016 – 0.0033 in.)

Maximum thrust clearance: 0.12 mm (0.0047 in.)

If the thrust clearance is greater than the maximum, replace the camshaft. If necessary, replace the bearing caps and cylinder head as a set.

(c) Remove the camshafts.

20. INSPECT CAMSHAFT GEAR BACKLASH

(a) Install the camshafts without installing the exhaust cam sub-gear and the front bearing cap.

( EM-59 )

(b) Using a dial indicator, measure the backlash.

Standard backlash: 0.020 – 0.200 mm (0.0008 – 0.0079 in.)

Maximum backlash: 0.30 mm (0.0188 in.)

If the backlash is greater than the maximum, replace the camshafts.

(c) Remove the camshafts.

Also, Read:

21. INSPECT VALVE LIFTERS AND LIFTER BORES

(a) Using a calliper gauge, measure the lifter bore diameter of the cylinder head.

Lifter bore diameter: 31.000 – 31.016 mm (1.2205 – 1.2211 in.)

(b) Using a micrometre, measure the lifter diameter at the valve lifter centerline, 12.3 – 12.7 mm (0.484 – 0.500 in.) from the valve lifter head.

Lifter diameter: 30.966 – 30.976 mm (1.2191 – 1.2195 in.)

(c) Subtract the lifter diameter from the lifter bore diameter.

Standard oil clearance: 0.024 – 0.050 mm (0.0009 – 0.0020 in.)

Maximum oil clearance: 0.07 mm (0.0028 in.)

If the oil clearance is greater than the maximum, replace the lifter.

If necessary, replace the cylinder head.

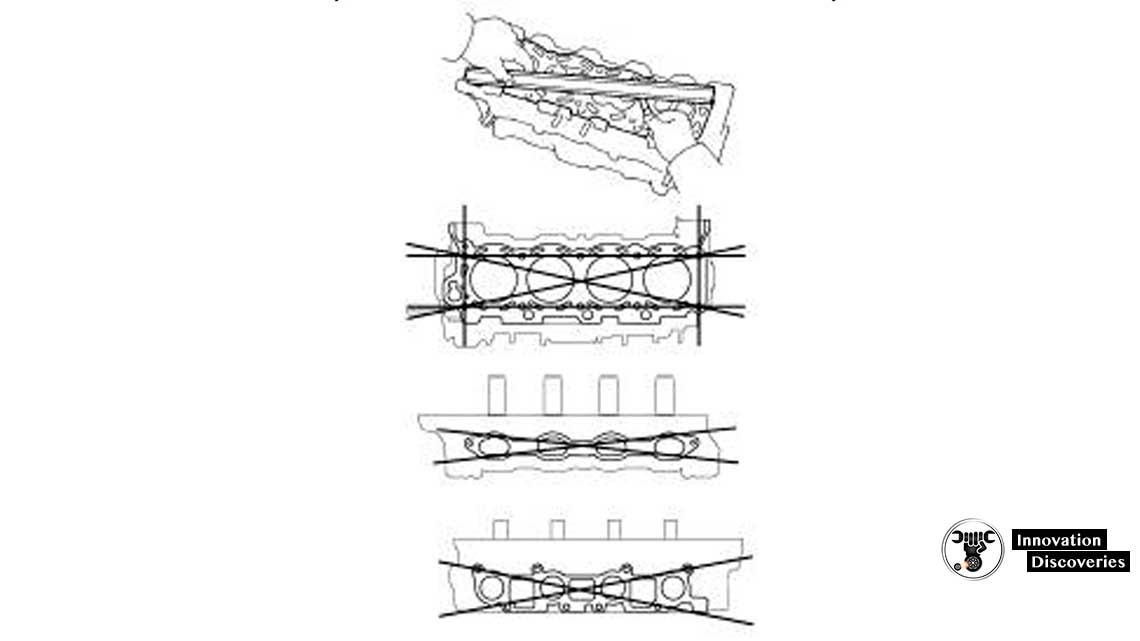

22. INSPECT INTAKE MANIFOLD

(a) Upper intake manifold: Using a precision straight edge and a feeler gauge, measure the surface contacting of the lower intake manifold for a warp.

Maximum warpage: 0.15 mm (0.0059 in.)

If the warp is greater than the maximum, replace the upper intake manifold.

(b) Lower intake manifold: Using a precision straight edge and a feeler gauge, measure the surface contacting of the cylinder head and the upper intake manifold for warpage.

Maximum warpage: 0.15 mm (0.0059 in.)

If the warp is greater than the maximum, replace the lower intake manifold.

23. INSPECT EXHAUST MANIFOLD

Using a precision straight edge and a feeler gauge, measure the surface contacting of the cylinder head for a warp.

Maximum warpage: 0.50 mm (0.0197 in.)

If the warp is greater than the maximum, replace the manifold.

24. INSPECT CYLINDER HEAD BOLTS

Using vernier callipers, measure the thread outside diameter of the bolt.

Standard outside diameter: 9.810 – 9.960 mm (0.3862 – 0.3921 in.)

Minimum outside diameter: 9.700 mm (0.3819 in.)

If the diameter is less than the minimum, replace the bolt.

Download: 1996 Toyota Land Cruiser Electrical Wiring Diagram

Visit Forum

Visit Our Friendly Website