Introduction

Clutch systems have been a fundamental component of automotive engineering since the invention of the manual transmission. As technology has evolved, so too have clutch systems, incorporating advanced materials, hydraulics, and electronics to improve performance, efficiency, and ease of use.

In this article, we delve into the various modern clutch systems that power today’s vehicles, exploring their unique characteristics and applications.

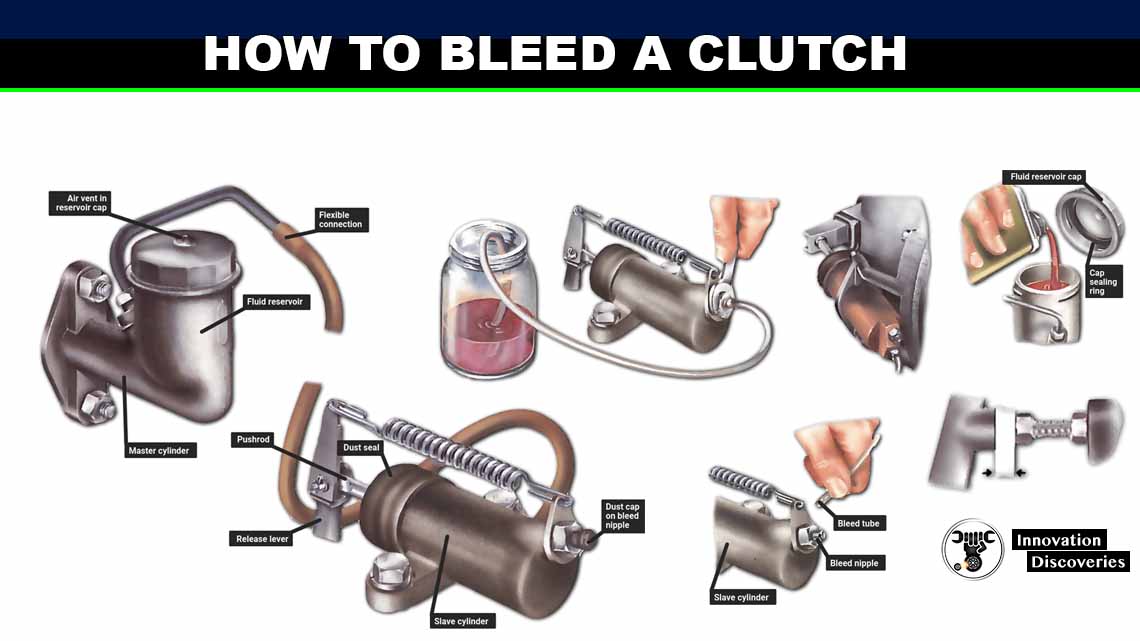

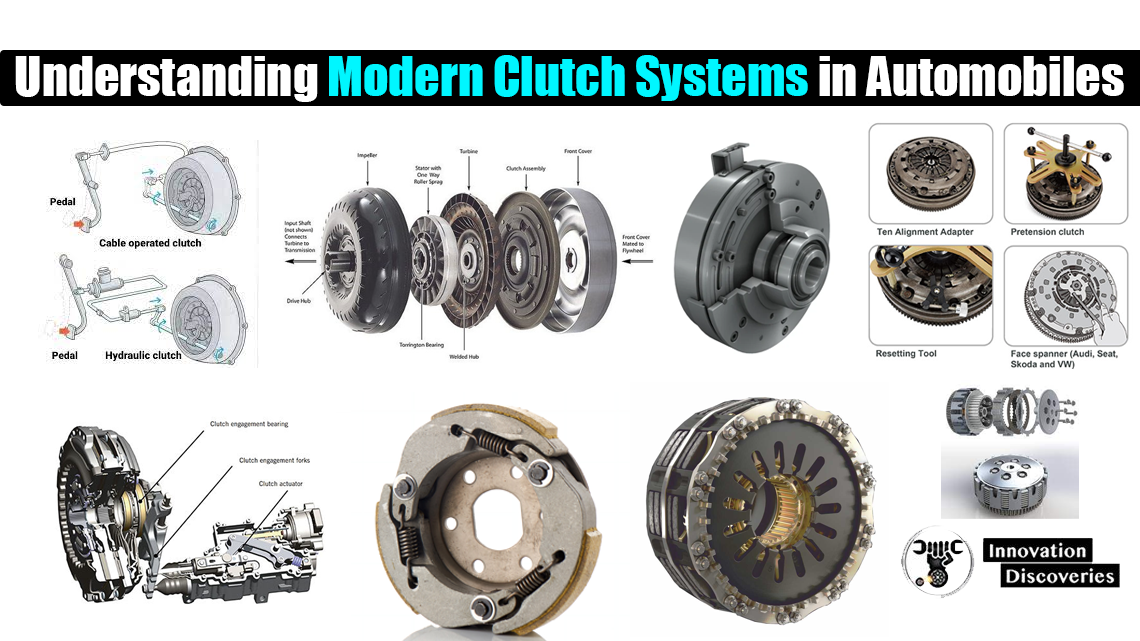

1. Hydraulic Clutch System

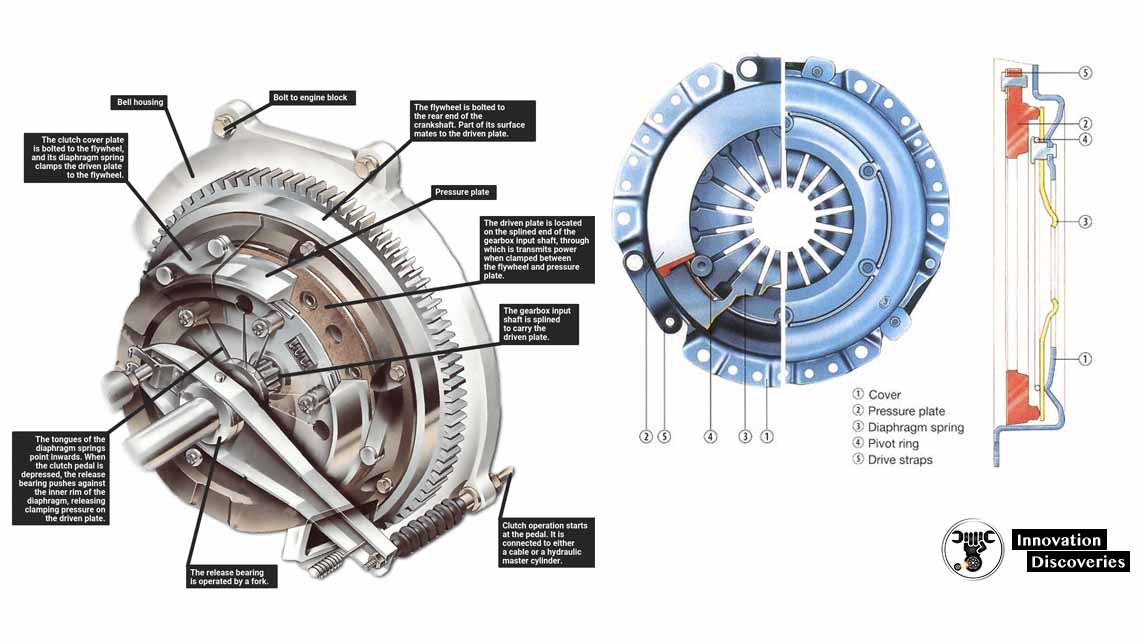

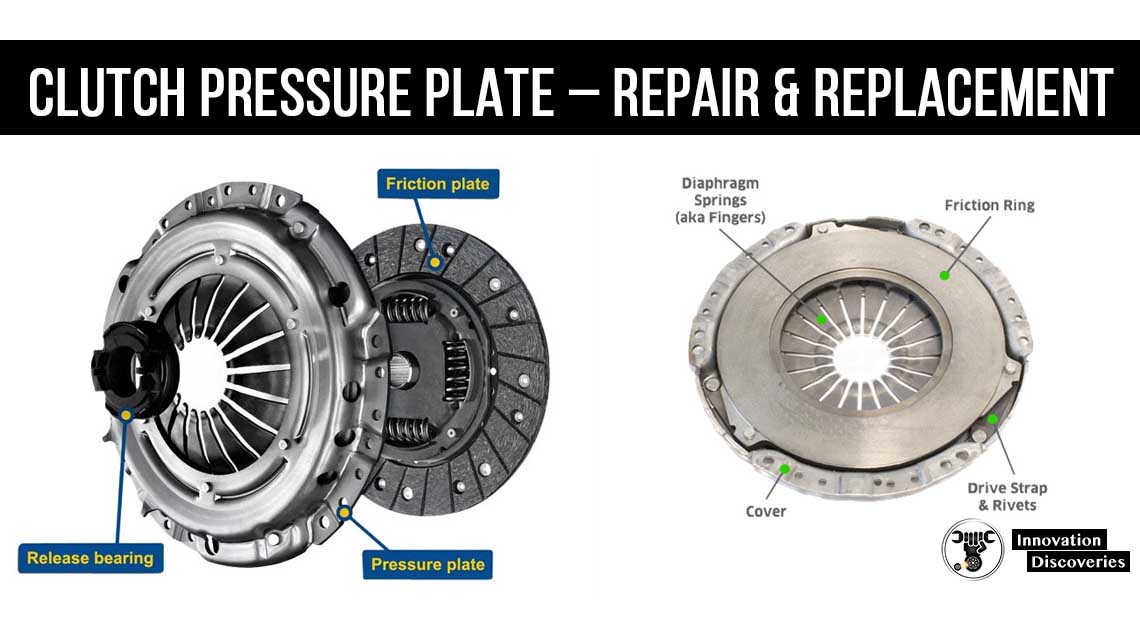

The hydraulic clutch system is a significant improvement over traditional mechanical linkage systems. It utilizes hydraulic fluid to transfer pressure from the clutch pedal to the clutch mechanism, ensuring smoother and more consistent engagement.

The system typically consists of a master cylinder connected to the clutch pedal and a slave cylinder near the clutch. When the clutch pedal is pressed, hydraulic fluid moves from the master cylinder to the slave cylinder, engaging the clutch.

Advantages:

- Smoother engagement

- Consistent performance

- Reduced pedal effort

Hydraulic clutches are commonly found in both manual and automatic transmissions, enhancing drivability and comfort.

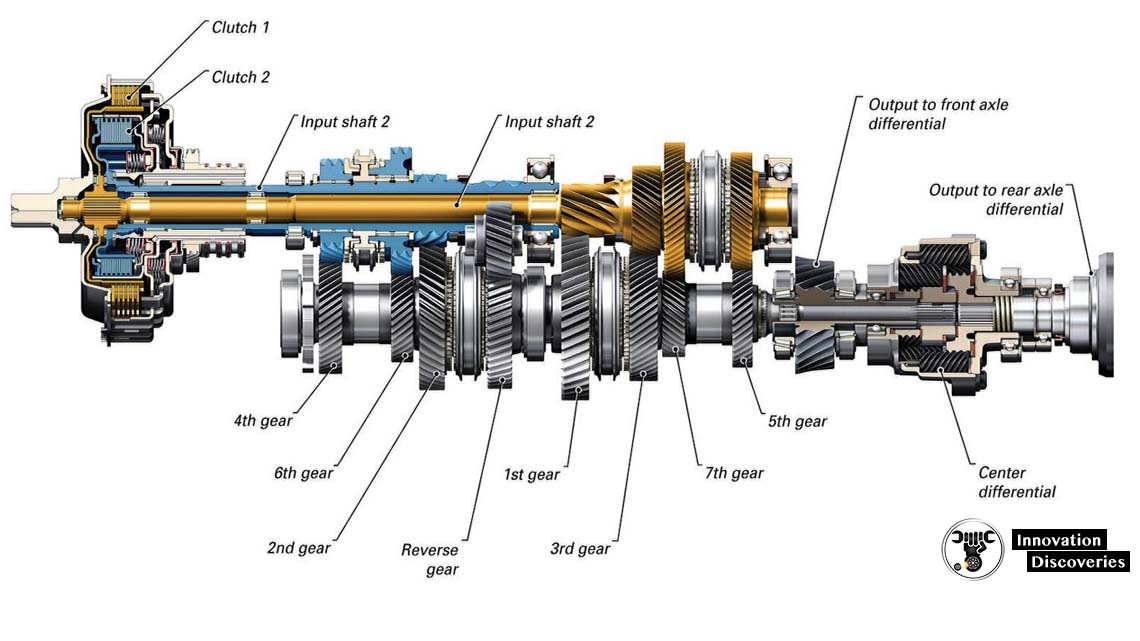

2. Dual-Clutch Transmission (DCT)

The Dual-Clutch Transmission represents a blend of manual and automatic transmission technologies. It employs two separate clutches: one for odd-numbered gears and another for even-numbered gears.

This setup allows for rapid and seamless gear changes, as the next gear is pre-selected by the second clutch while the first clutch is still engaged.

Advantages:

- Faster gear shifts

- Improved fuel efficiency

- Smooth power delivery

DCTs are popular in high-performance vehicles but are also increasingly available in mainstream models, offering a sporty yet practical driving experience.

3. Automated Manual Transmission (AMT)

Automated Manual Transmission combines the efficiency of a manual transmission with the convenience of an automatic. An electronic control unit (ECU) automates clutch engagement and gear shifts, eliminating the need for a clutch pedal.

Advantages:

- Improved fuel economy

- Reduced driver fatigue

- Cost-effective compared to traditional automatics

AMTs are particularly useful in urban driving conditions, providing ease of use without sacrificing fuel efficiency.

4. Torque Converter Clutch (TCC)

Common in automatic transmissions, the Torque Converter Clutch locks the torque converter at higher speeds to improve fuel efficiency by eliminating slippage. This lock-up feature enhances the direct connection between the engine and transmission, offering better fuel economy and performance.

Advantages:

- Increased fuel efficiency

- Improved drivability

- Smoother acceleration

TCCs are integral to modern automatic transmissions, making them more efficient and responsive.

5. Centrifugal Clutch

The centrifugal clutch automatically engages based on engine speed, making it ideal for applications where simplicity and ease of use are paramount. It is commonly found in scooters, go-karts, and small motorcycles.

Advantages:

- Automatic engagement

- Simple design

- Low maintenance

This type of clutch is perfect for low-power applications, where ease of use and reliability are crucial.

6. Electromagnetic Clutch

Electromagnetic clutches use electromagnetic force to engage and disengage the clutch. Found in hybrid vehicles and advanced transmission systems, these clutches allow for precise control and integration with electronic systems.

Advantages:

- Precise control

- Quick engagement and disengagement

- Integration with hybrid systems

Electromagnetic clutches are crucial for modern hybrid vehicles, providing seamless transitions between electric and combustion power.

7. Self-Adjusting Clutch (SAC)

The Self-Adjusting Clutch is designed to maintain optimal pedal feel by automatically compensating for wear. This reduces the need for manual adjustments and extends the clutch’s lifespan.

Advantages:

- Consistent pedal feel

- Reduced maintenance

- Extended clutch life

SACs are commonly used in commercial vehicles and some passenger cars, offering durability and reliability.

8. Carbon Clutch

Made from carbon-composite materials, carbon clutches offer high strength, lightweight, and excellent heat resistance. These characteristics make them ideal for high-performance and racing applications.

Advantages:

- High thermal resistance

- Lightweight

- High torque capacity

Carbon clutches are favored in racing and high-performance vehicles, where durability and performance are critical.

9. Multi-Plate Clutch

Multi-plate clutches use multiple friction discs to increase the contact surface area, providing higher torque capacity and smoother engagement. They are often used in motorcycles, racing cars, and high-performance vehicles.

Advantages:

- Increased torque capacity

- Smoother engagement

- Compact design

This type of clutch is essential for applications requiring high power transmission in a compact form.

Conclusion

Modern clutch systems have evolved to meet the diverse demands of today’s automotive landscape. From hydraulic clutches that provide smooth and consistent engagement to advanced dual-clutch systems that offer lightning-fast gear changes, these technologies enhance performance, efficiency, and driving comfort.

Understanding these systems can help drivers and enthusiasts appreciate the complexity and innovation behind their vehicles’ seamless operation. Whether it’s for everyday commuting or high-performance driving, modern clutch systems play a crucial role in delivering a superior driving experience.

Discover More:

What are the Main Components of the Gear Box?

CHECKING AND REMOVING A CLUTCH MASTER CYLINDER

Visit Forum

Visit Our Friendly Website