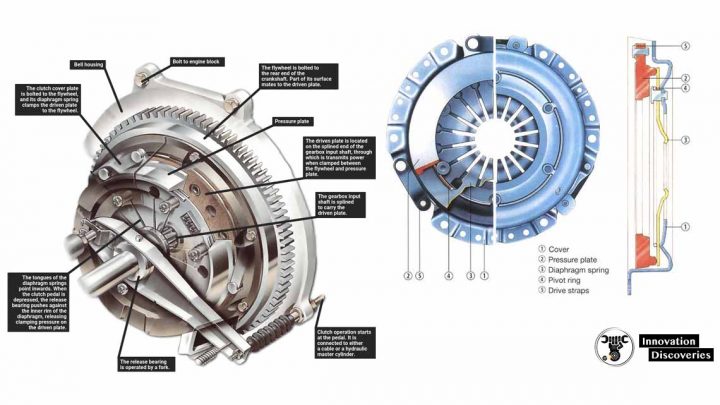

If a clutch fails to disengage fully when the pedal is pressed, The problem may be the clutch itself. In a hydraulic clutch, However, the problem may lie in the master or slave hydraulic cylinders.

Worn or ill-fitting seals may allow hydraulic fluid to leak past the piston in either cylinder, So, the slave piston does not travel far enough to disengage the clutch.

Any sort of leak will have the same effect and air might get into the system.

If the system has air in it, the action of the pedal may feel ‘spongy’, Whereas with other faults the pedal may feel normal, Although the clutch does not work properly.

Also, read – How a car clutch works

If seals are worn or damaged, fit a service kit which includes new seals.

The cylinder bores may have worn or become rough hydraulic fluid is hygroscopic, Absorbing moisture from the atmosphere, Which can cause corrosion in the bores.

In this case, fitting a new cylinder is the only remedy.

Trying to smooth the bore with abrasives only makes it worse, And the roughness quickly wears out new seals.

Lack of fluid is easily fixed by topping up the master-cylinder reservoir, But you still have to find out why the fluid level was low.

There should be virtually no loss in normal use.

Remove air from the system by bleeding it. Check the entire system and repair any leaks.

Also, read – How It Works: Cylinder deactivation

If you replace either a master or a slave cylinder, Buy one of the same manufacturers, and be sure you get the right model or An approved successor.

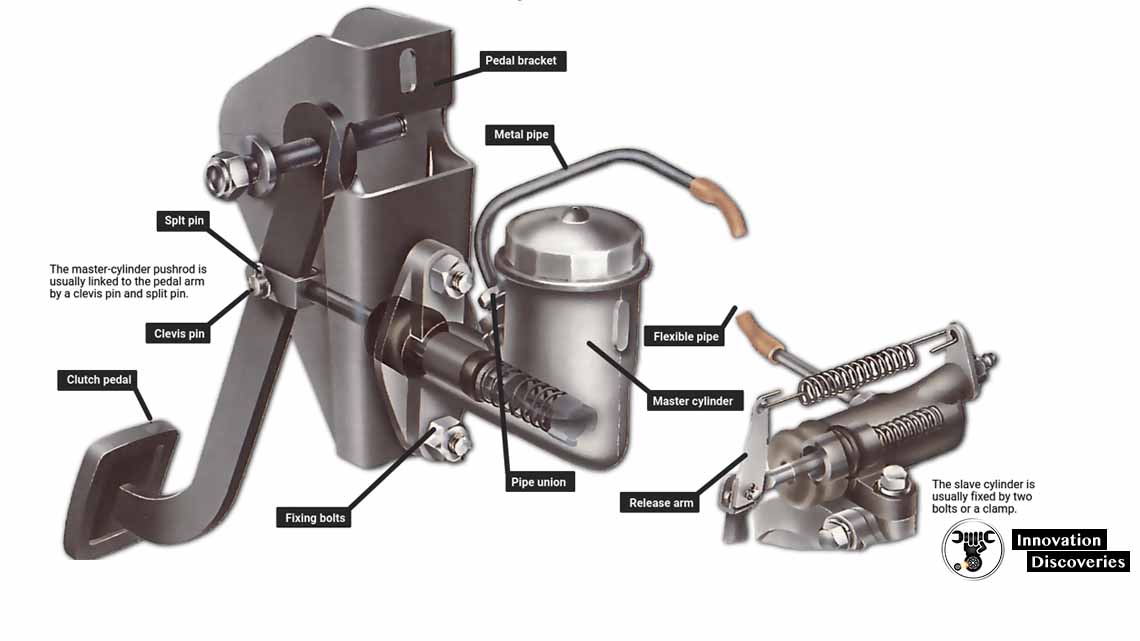

Clutch master cylinder

A clutch master cylinder is a single unit with its fluid reservoir.

Checking a clutch system

Master cylinders

The clutch cylinder is the one on the right, looking from the front of the car.

The clutch master cylinder is usually found on the bulkhead next to the brake cylinder. Usually each cylinder is directly in front of its pedal,

So, the clutch cylinder is the one on the right as you look from the front of the car.

Brakes with servo assistance (See Replacing a master cylinder and servo unit ) May have a different arrangement, but it should be clear which cylinder is which.

If the clutch fluid is low, look all over both master and slave cylinders and

The pipe that connects them for signs of a leak. Pull back the lip of the dust cover on both cylinders.

If there is the hydraulic fluid inside the cover the piston seal is worn Or damaged or the cylinder may be scored.

If you find a leak, remove the faulty part and overhaul or replace it.

If you can find no trace of a leak, Fitting a complete service kit to both cylinders may cure the trouble.

If the fluid level is normal but the clutch ‘drags’ (will not disengage properly), and particularly if the pedal feels spongy, there is air in the system. Bleed the system.

Removing a clutch master cylinder

Set a container to catch any fluid that runs out When you remove the cylinder and protect paintwork with plastic sheeting or absorbent rags.

Normally the master cylinder is held to the bulkhead by two bolts,

Or nuts on studs. Unscrew these and lift off the cylinder.

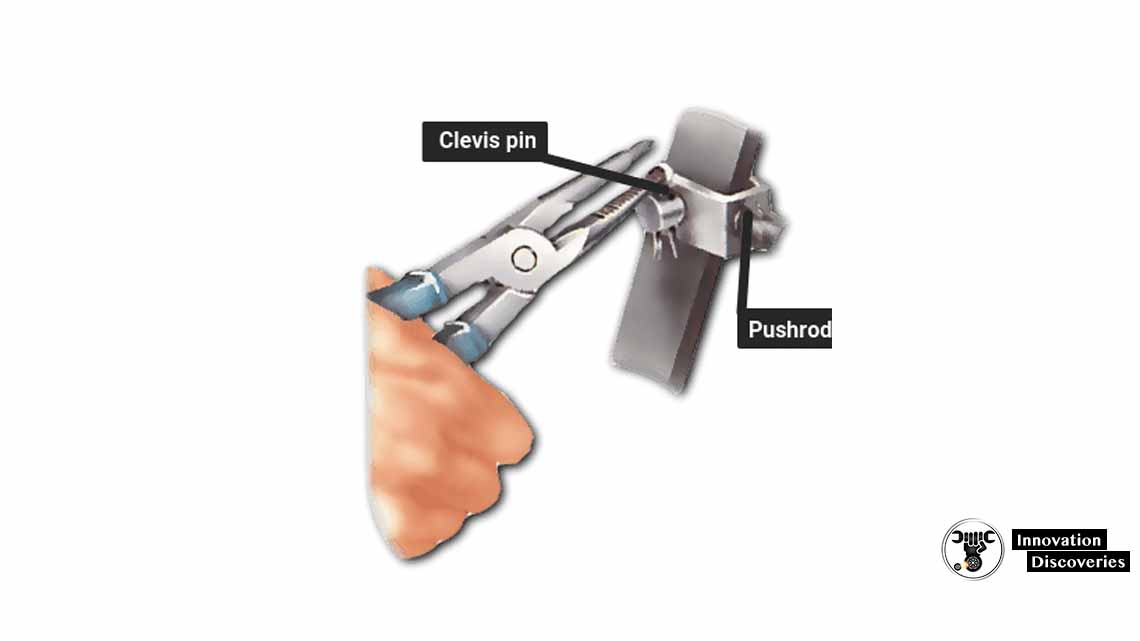

Disconnect the clutch pedal from the master cylinder pushrod.

Most cars have a simple clevis pin on the pedal arm which passes through a fork on the end of the pushrod.

Remove the split pin or retaining clip to release the clevis pin.

(Use a new split pin when refitting.)

If the reservoir is not integral with the cylinder, Remove the reservoir cap. Put a small sheet of plastic over the mouth of the reservoir, then screw the cap back on over the plastic.

This reduces fluid loss through the pipe to the cylinder by blocking the vent hole in the cap. Unscrew the union nut connecting the pipe to the cylinder.

Pull the reservoir or its connecting pipe off the cylinder and Quickly plug the hole in the reservoir or the end of the pipe with a small rubber bung or cork.

See More:

One Comment