Introduction

In the world of internal combustion engines, a vital component that plays a crucial role in the functioning of the engine is the piston sleeve.

This unassuming cylindrical structure is often overlooked, but it serves a critical purpose in ensuring the smooth operation and longevity of an engine.

In this article, we will delve into the functions, types, and maintenance of piston sleeves.

Functions of a Piston Sleeve

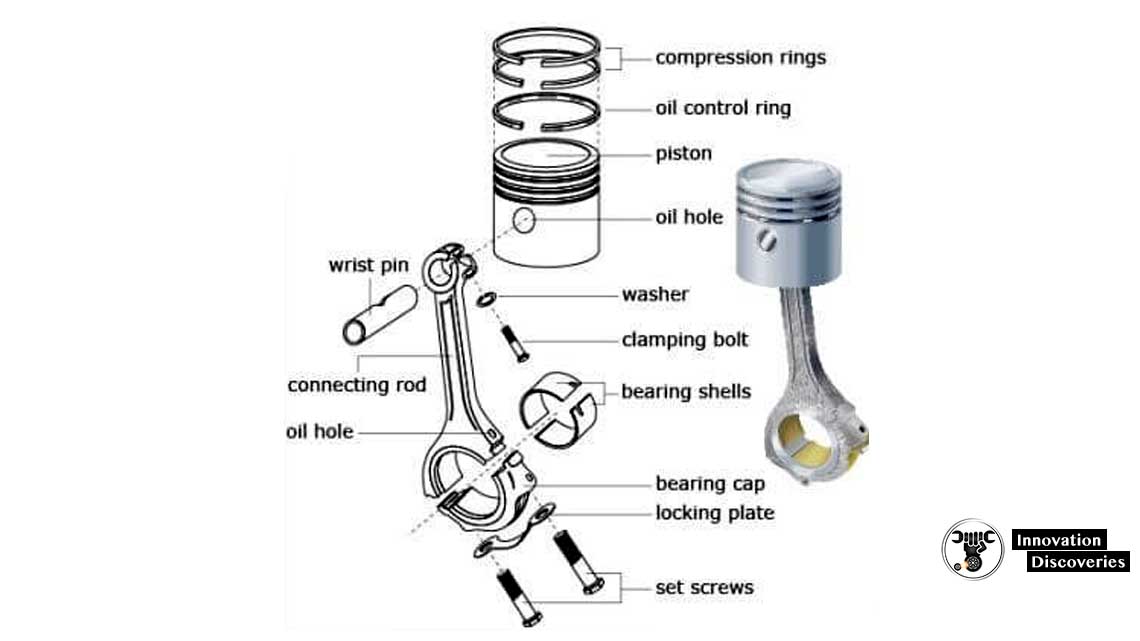

A piston sleeve, also known as a cylinder liner, is a replaceable cylindrical component that fits inside the cylinder of an engine block. Its primary functions are:

1. Reduction of Friction and Wear

Piston sleeves are typically made of durable materials like cast iron or steel. Their smooth surface reduces friction between the piston and cylinder wall, preventing premature wear.

2. Heat Dissipation

During the combustion process, immense heat is generated. The piston sleeve aids in dissipating this heat away from the combustion chamber, preventing overheating and potential damage to the engine.

3. Sealing

Piston sleeves provide a tight seal between the combustion chamber and crankcase, ensuring that combustion gases are contained and do not leak into the crankcase, and vice versa.

4. Maintenance of Compression

They play a vital role in maintaining compression within the engine. Without proper compression, the engine’s performance would be severely compromised.

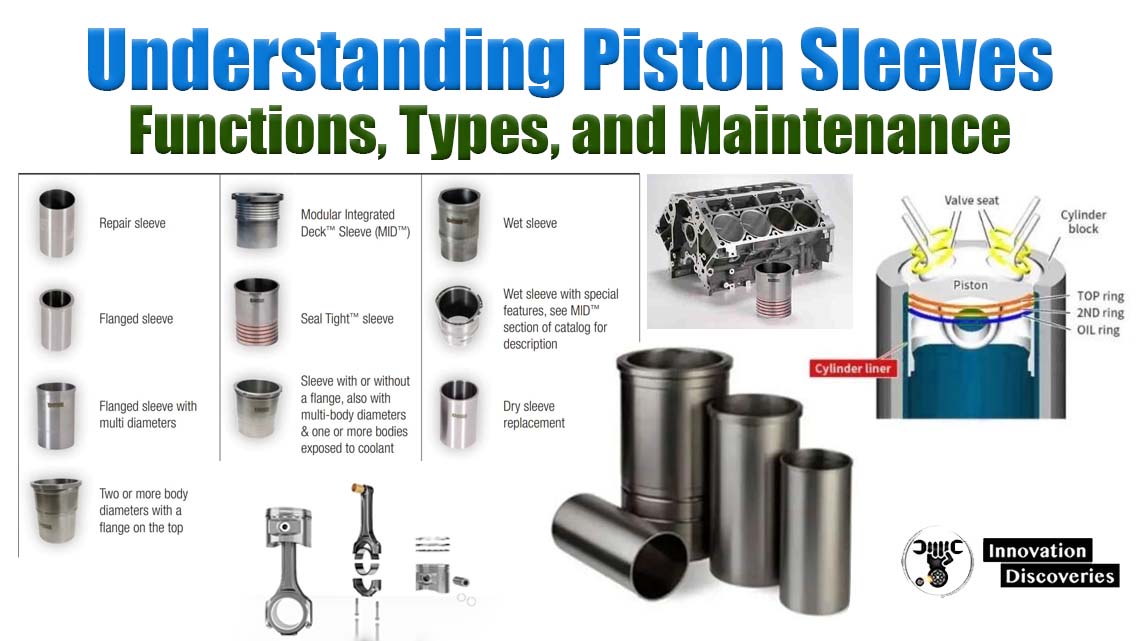

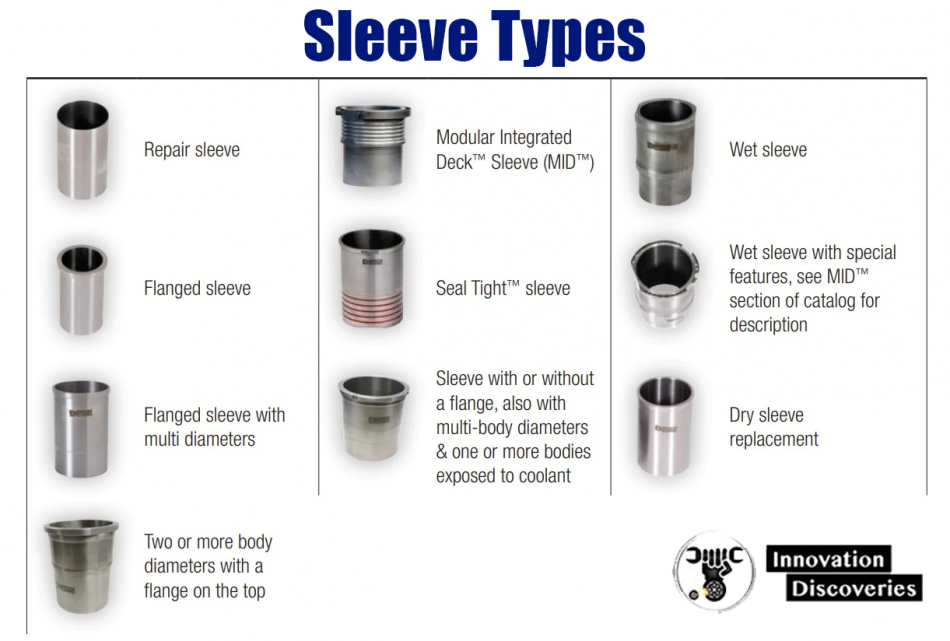

Types of Piston Sleeves

Piston sleeves come in various types, each designed to cater to specific engine requirements:

1. Dry Sleeve

Dry sleeves are not in direct contact with the coolant. They rely on a press-fit into the engine block and do not have any contact with the coolant passages.

2. Wet Sleeve

Wet sleeves are in direct contact with the coolant, which helps in dissipating heat more efficiently. They are typically used in heavy-duty applications where engines are subjected to high loads and extended operation times.

3. Flanged Sleeve

Flanged sleeves have an extended flange at the top, which provides additional support and stability. These are commonly used in high-performance engines.

4. Nikasil Sleeve

Nikasil is a proprietary nickel-silicon carbide coating applied to aluminum cylinders. This type of sleeve provides excellent wear resistance and reduced friction.

Maintenance Tips

Proper maintenance of piston sleeves is crucial for the longevity and performance of an engine. Here are some tips:

1. Regular Inspection

Periodic visual inspections can reveal early signs of wear or damage. Any irregularities should be addressed promptly.

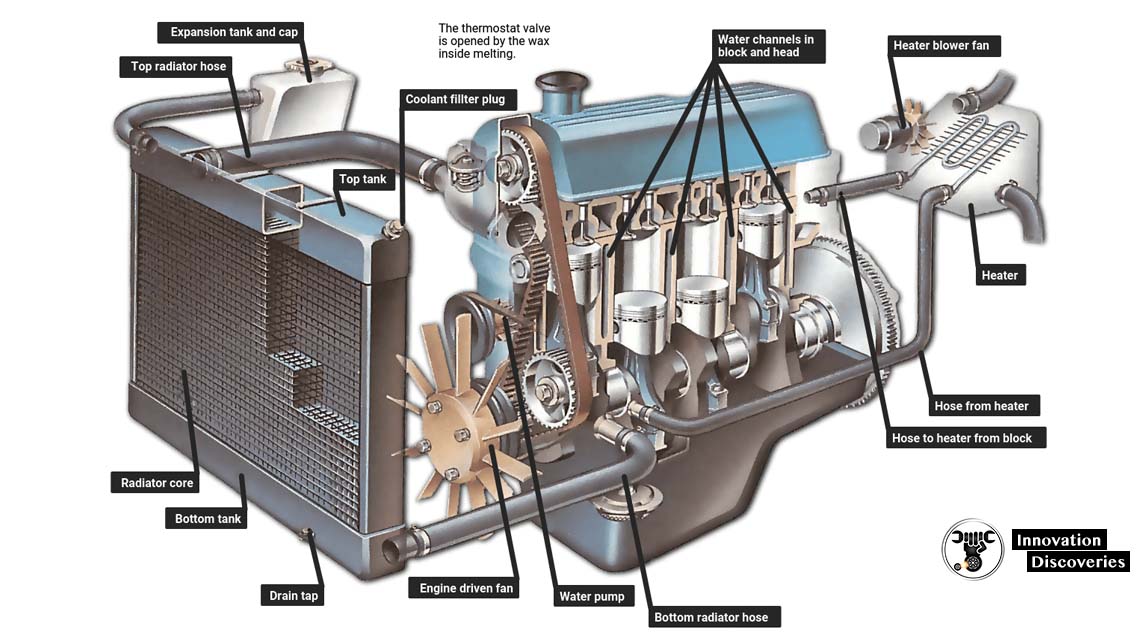

2. Maintain Coolant Quality

In engines with wet sleeves, ensuring the coolant is clean and of the correct type is crucial. Contaminated or improper coolant can lead to premature sleeve wear.

3. Avoid Overheating

Avoiding overheating of the engine is essential to prevent damage to the sleeve. This can be achieved by maintaining proper coolant levels and ensuring the cooling system is in good working condition.

4. Proper Lubrication

Using high-quality engine oil that meets the manufacturer’s specifications is vital for reducing friction and wear on the sleeve.

Conclusion

While the piston sleeve may seem like a minor component, its role in the engine’s operation is nothing short of indispensable.

Understanding its functions, types, and how to properly maintain it can contribute significantly to the longevity and efficiency of an internal combustion engine.

Regular inspections and adherence to maintenance practices are key to ensuring that this unassuming cylinder continues to play its crucial role effectively.

Discover More:

Discover More:

Read More:

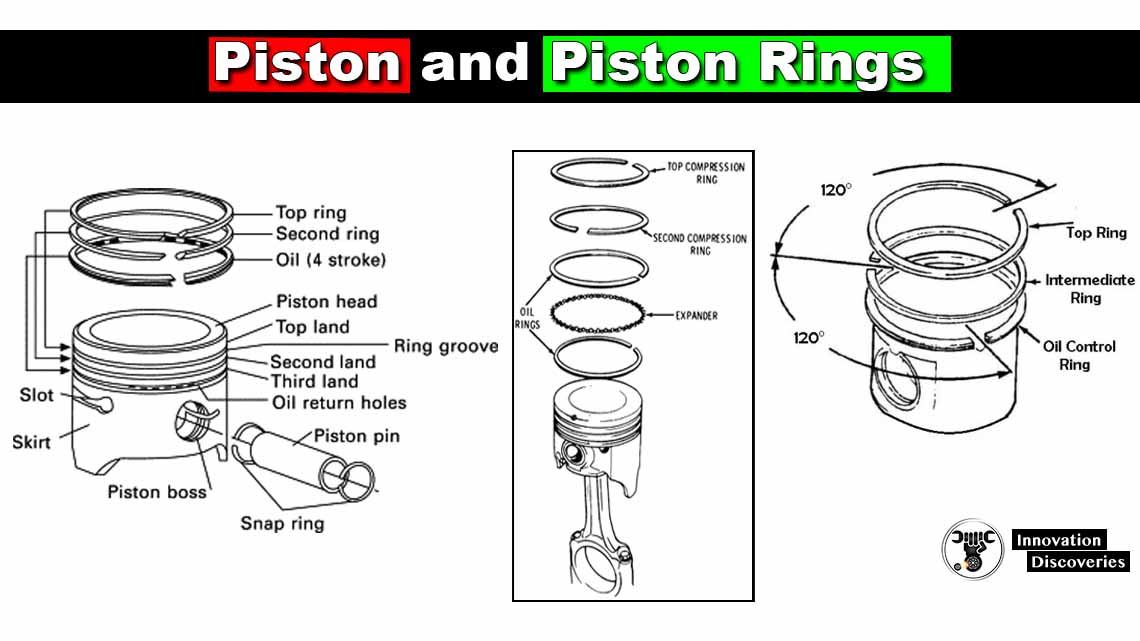

PISTON AND PISTON RINGS

3 SYMPTOMS OF BAD VALVE SEALS AND PISTON RINGS AND REPLACEMENT COST

WHAT IS PISTON CLEARANCE? AND WHY IT IS NECESSARY?

Read More:

For More Knowledge

Visit Forum

Visit Our Friendly Website