Air Cleaners and It’s Types

The fuel system provides a combustible air-fuel mixture to the engine. The mixing of air and fuel takes place in the carburetor.

For the normal running of the petrol engine, one part of petrol requires 16 parts of air by weight.

It is a great amount of air that passes through the carburetor to the engine in comparison to petrol.

Also, Read: How Often To Change Air Filter In Car? The Answer

The air is likely to contain dust and dirt. If the air is not cleaned before it exerts the carburetor, the dust and dirt particles will seriously damage the engine.

They will foul the carburetor parts and spark plug, increase abrasive wear on piston, piston rings, cylinder walls, bearings, and any relative moving parts.

Therefore, the air must be cleaned before it enters the carburetor.

For this purpose, an air cleaner is used.

It is mounted on the air horn or air entrance of the carburetor.

All air entering the engine through the carburetor must first pass through the air cleaner.

The air cleaner not only cleans the air by removing the dust and dirt particles but also muffles the noise resulting from the intake of air through the carburetor, muffle, and valve ports.

Besides, the air cleaner acts as a flame arrester in case the engine backfires through the carburetor.

Backfiring occurs at certain times due to the ignition of the air-fuel mixture in the cylinder before the intake valve closes.

When this happens, there is a momentary flask-back through the carburetor.

The air cleaner prevents this flame from spreading through the carburetor and possibly igniting the petrol fumes outside the engine.

Types of Air Cleaners in Engine

Air cleaners are classified based on principles of filtration and the nature of filtering material.

The type of filter adopted for a particular engine depends upon the atmosphere in which the engine has to operate.

The air cleaners generally used are of the following types:

- Oil bath type air cleaner.

- Dry-type air cleaner.

- Oil wetted type air cleaner.

- Paper pleated type air cleaner.

- Centrifugal type air cleaner.

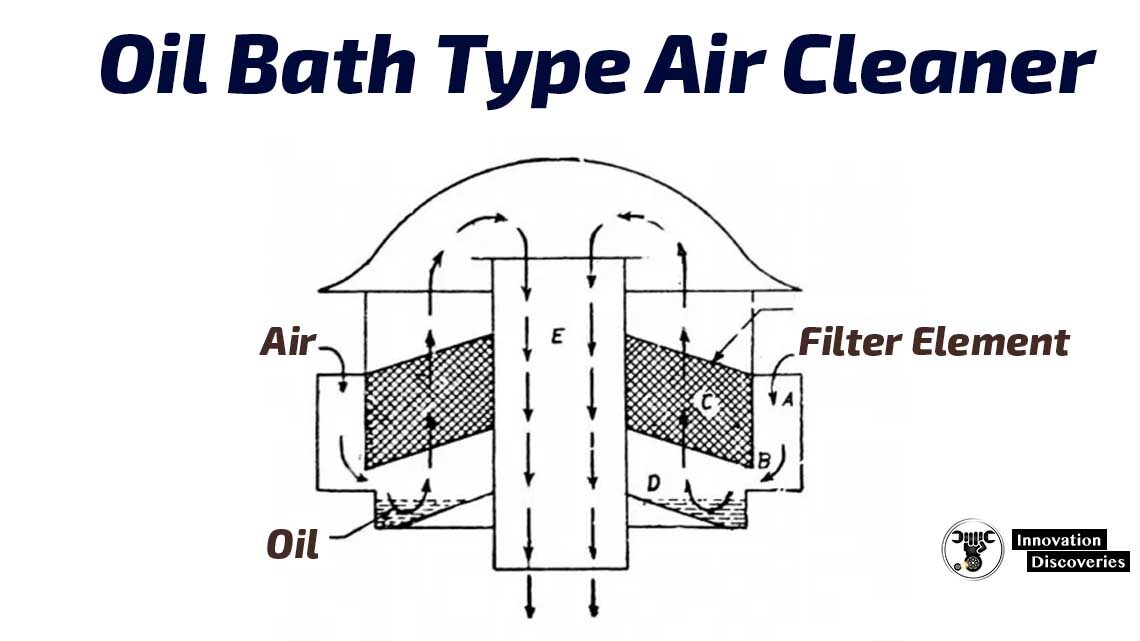

1. Oil Bath Type Air Cleaner

It is a heavy-duty air cleaner. It is designed in a variety of shapes.

The type shown in the figure is designed to be placed on the top of the carburetor and to be clamped to the air horn.

It consists of a filter element saturated with oil. At the bottom, there is a separate oil pan. The operation of air cleaning is carried out in two stages.

Types of Air Cleaner in Engine – Oil bath type air cleaner

In the first stage, the airstrikes on the oil surface and then reverse upward into the filter element.

The dust particles are applied to the oil surface and absorbed by it.

In the second stage, the partly cleaned air passes through the filter element in which the remaining dust particles are retained.

Finally, the cleaned air passes to the carburetor through the passage away.

Depending on the severity of the operation, this type of air cleaner is cleaned periodically. The filter is removed and cleaned carefully in petrol.

The oil in the cleaner is also replaced.

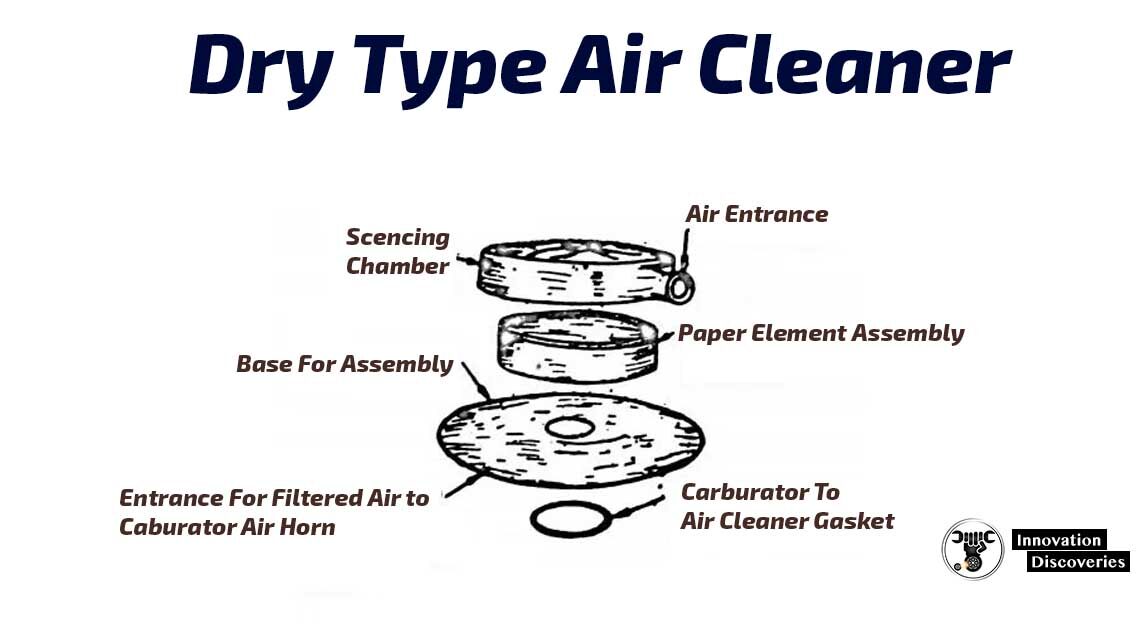

2. Dry Type Air Cleaner

It is a light-duty air cleaner. It consists of a cleaning element only and not the oil bath.

The cleaning element is a specially pleated element, over which is put a fine mesh screen to provide strength.

This cleaning element is enclosed in a silencing chamber.

The figure shows the part of a dry-type air cleaner.

Also, read : Basic Explanation of how a 2-stroke engine and carburetor work together

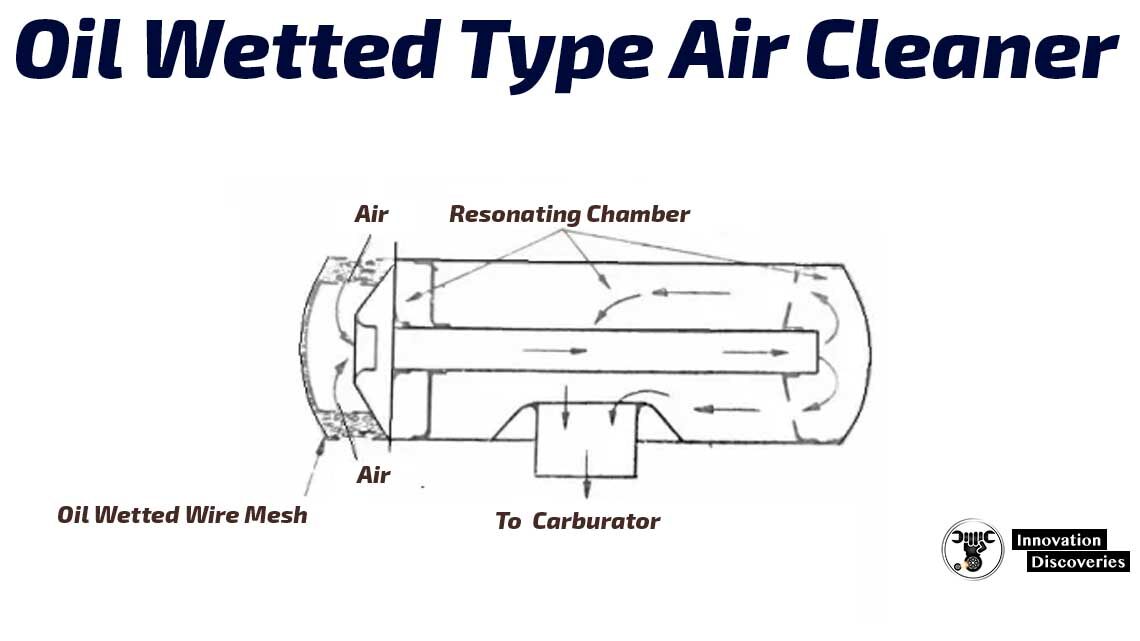

3. Oil Wetted Type Air Cleaner

It consists of a filtering element generally, wire mesh, coated with an oil film.

The air passes through this element, and the dust particles of the air adhere to the oil film. This type of air cleaner should be cleaned periodically, about every 800 km, by washing the wire mesh in petrol or paraffin.

After drying it properly, coat it with engine oil, allow it to drain, and again fit it for working.

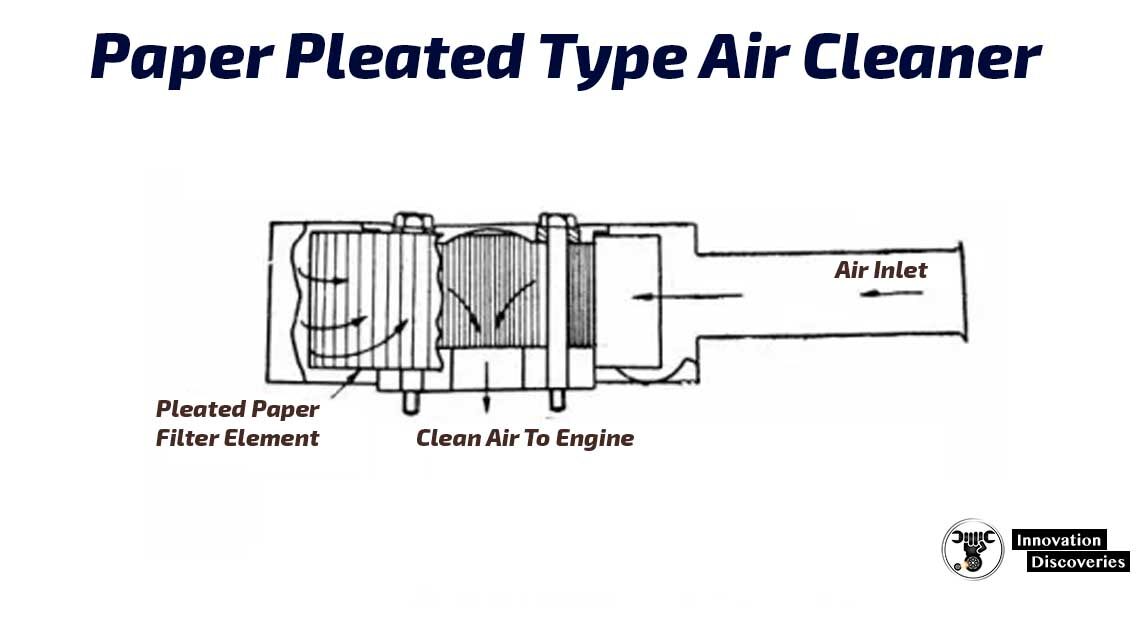

4. Paper Pleated Type Air Cleaner

It consists of a filtering element of the resin-impregnated paper. This type of air cleaner is made in the form as shown in the figure.

It has a high filtering efficiency. By pleating the paper element, a large filtering surface is provided, and yet restriction of airflow is a minimum.

The element should be cleaned periodically, about every 20,000 km.

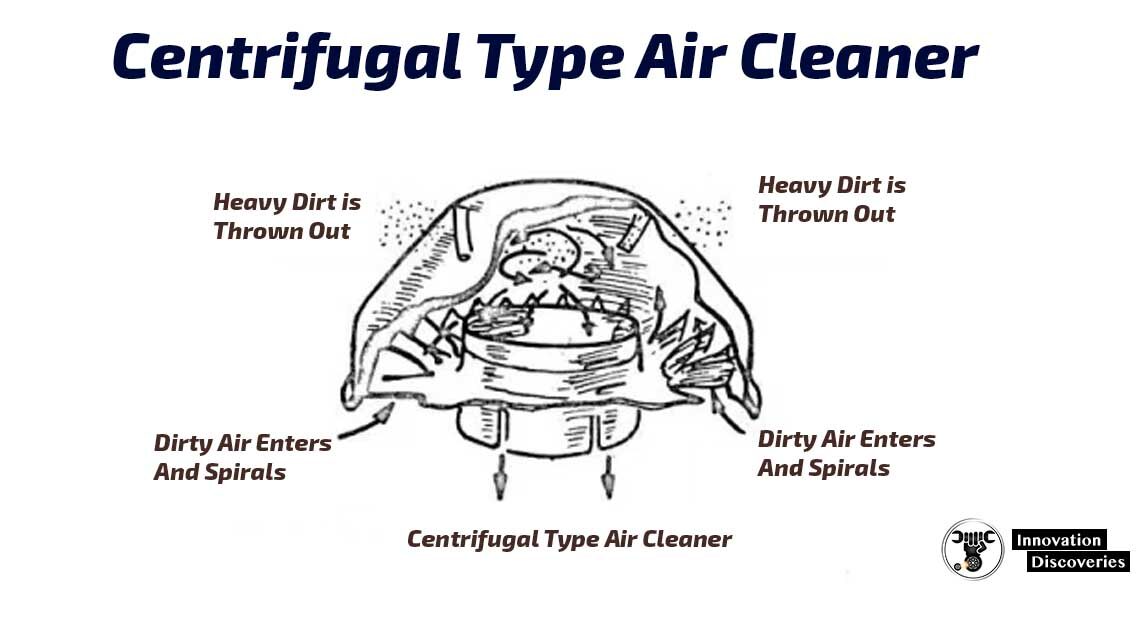

5. Centrifugal Type Air Cleaner

In this type of air cleaner, a whirling motion is given to the air due to which heavy dust particles are thrown out by the centrifugal force to the periphery of the casing, where they leave through slots.

Centrifugal type air cleaner

The main airflow passes through vanes set at an angle, to correct the airflow to a straight direction, and then enters the main air cleaner.

The air is not perfectly cleaned by this cleaner and hence it acts as first stage cleaner on installations dealing with heavy dust concentrations.

It is known as a centrifugal cleaner.

Read More:

- Gear Train -Uses & Types

- Adjusting a SU carburetor

- Supercharger and its types

- Carburetor Vs Fuel Injection: Which One Is The Better Option?