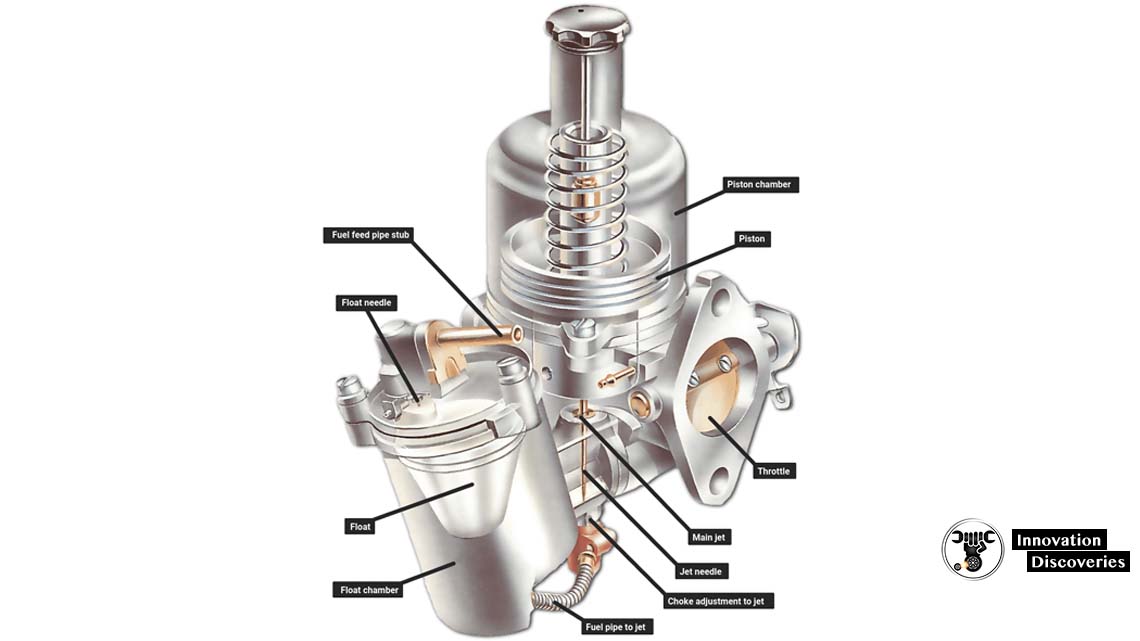

A Carburetor mixes fuel and air in the proportions,

And quantity the engine needs at any time.

It does this by spraying the fuel into the moving air stream through a jet,

So that the fuel vaporizes and makes an explosive mixture.

The faster an engine runs, the more air it sucks in.

The air passes through a narrowed neck inside the carburetor (called a venturi ), Which speeds up its flow at that point.

The SU is the simplest type of variable jet carburetor,

The other main type, the Stromberg,

Has a rubber diaphragm instead of a piston.

As air flows faster its pressure drops,

So there is a slight vacuum inside the venturi.

The fuel jet opens into the venturi, and the partial vacuum sucks fuel through,

The jet into the air stream.

The speed of the engine is controlled by a throttle,

A movable circular flap linked to the accelerator pedal which partly blocks the venturi to admit variable amounts of air.

There has to be some way of governing the fuel flow through the jet,

So that the mixture is right so that the fuel is in the right proportion to the air.

The simplest way of doing this is with a variable jet.

The variable-jet carburetor

The fuel jet is partly blocked by a tapered needle,

Which can be raised progressively to unblock it.

The needle is fixed to a piston, which is free to slide up and down in a chamber above the jet.

The top of the chamber is linked to the inlet manifold through a narrow passage.

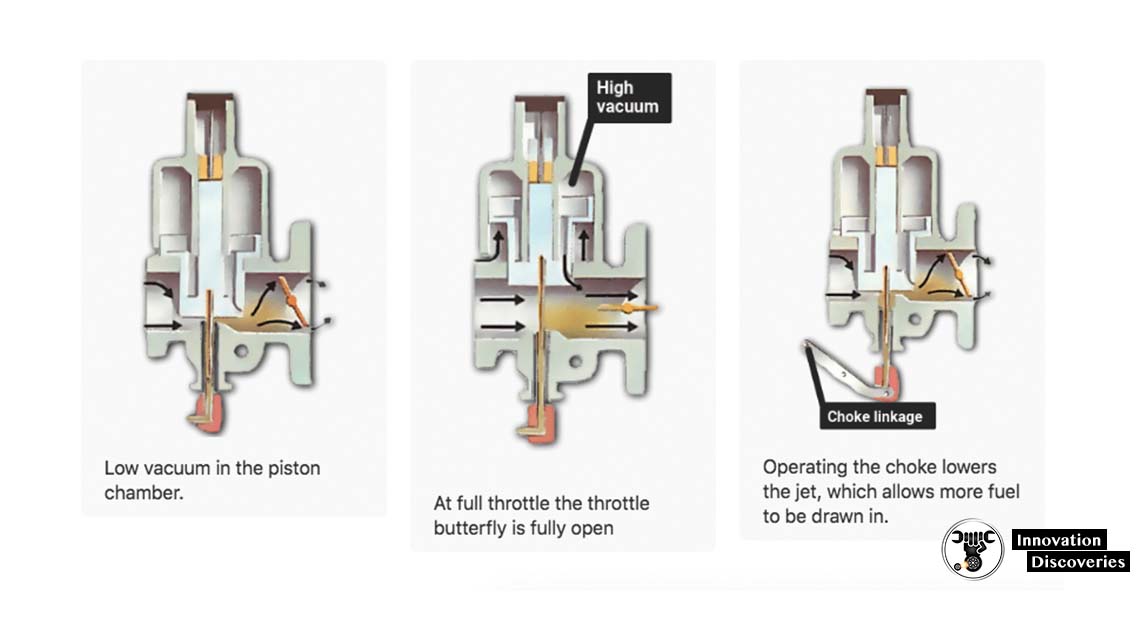

When the engine is idling, low manifold depression and,

A light spring causes the piston to sit at the bottom of the chamber,

And the needle almost completely blocks the jet. Little fuel flows.

As the throttle opens, airflow to the engine increases.

The engine speeds up and sucks in yet more air.

This suction creates a partial vacuum in the inlet manifold,

And therefore also at the top of the chamber, which is connected to it.

The vacuum is more powerful than the

Slight vacuum in the venturi under the piston,

So it draws the piston up, unblocking the jet and letting more fuel flow.

A sudden burst of acceleration causes a sudden rush of mixture into the inlet manifold,

So that the vacuum there lessens for an instant.

That would allow the piston to fall, closing the jet and weakening the mixture.

But the problem is avoided by having an oil-filled damper attached to the piston,

Which prevents it from moving quickly. Therefore, the mixture does not suddenly become too weak for smooth combustion.

Starting from cold

An engine needs an extra-rich mixture of more petrol, less air for starting from cold.

On some variable-jet carburetors,

This is provided for by the jet being lowered a short way,

So that it is less blocked by the needle and dispenses more fuel than usual.

On others, neat fuel is atomized by the rotation of a disc of progressively larger-sized holes.

On a fixed-jet carburetor (See How the fuel system works,

fixed-jet carburetors) the opposite happens,

Instead of more petrol being supplied to the carburetor,

The air supply is partly blocked off by a choke flap above the throttle.

However, both systems are referred to as ‘choke’ mechanisms,

Or cold-start enrichment systems.

On some cars, you have to set the choke yourself before starting,

Usually utilizing a pull-push control in the dashboard,

Or steering column or floor pan.

Other cars have an automatic choke which uses a bimetallic coiled strip,

A strip made of two different metals brazed together attached to the choke lever.

When the engine is cold, the choke is ‘on’. As the engine warms, so does the strip.

It expands with heat, but one of the metals expands more than the other,

So that the coiled strip bends and uncurls and progressively,

Moves the choke lever to off.

The float chamber

For a carburetor to maintain a steady fuel flow,

It needs to draw on a supply of fuel which is always kept at the same level.

That supply is provided by a float chamber attached to the carburetor.

The float chamber contains a pivoted float which bears against a needle,

Valve through which fuel enters the chamber.

Related Articles

How car heating and ventilation systems work

OXYGEN SENSORS /LAMBDA SENSOR/: PARTS, TYPES, WORKING PRINCIPLE AND LOCATION

4 Comments