Introduction

In the intricate dance of vehicle mechanics, various components work in harmony to provide a smooth and safe ride. Among these, the hub assembly stands as a crucial player that often goes unnoticed.

Nestled within the wheels, hub assemblies play a pivotal role in ensuring not only the vehicle’s performance but also the safety of its occupants.

This article dives into the world of hub assemblies, shedding light on their importance, construction, and maintenance.

Understanding Hub Assemblies

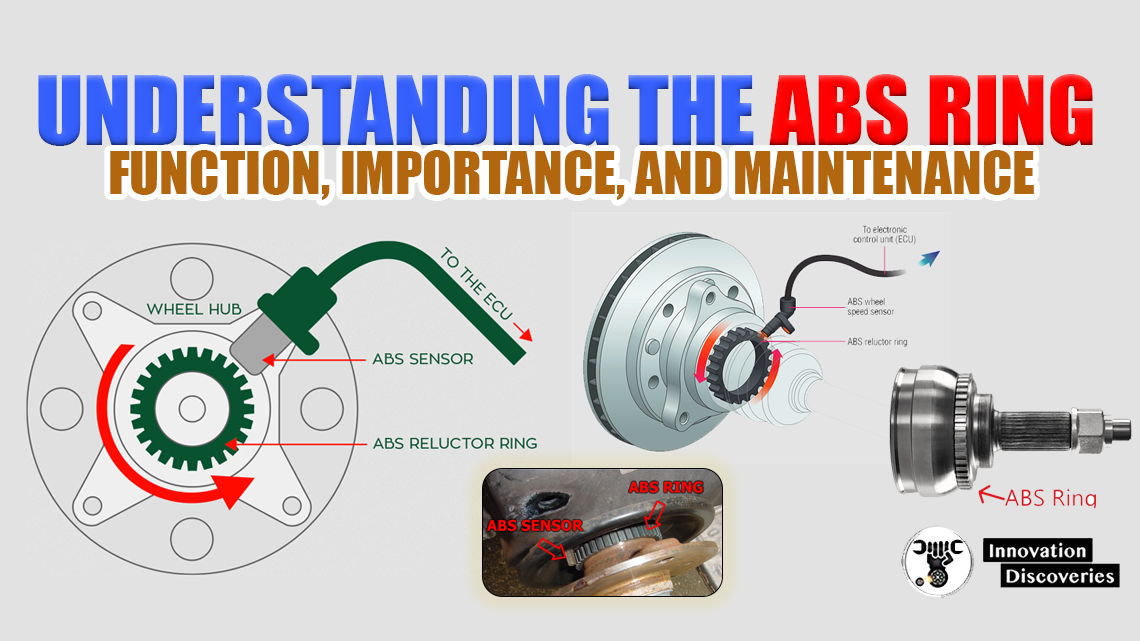

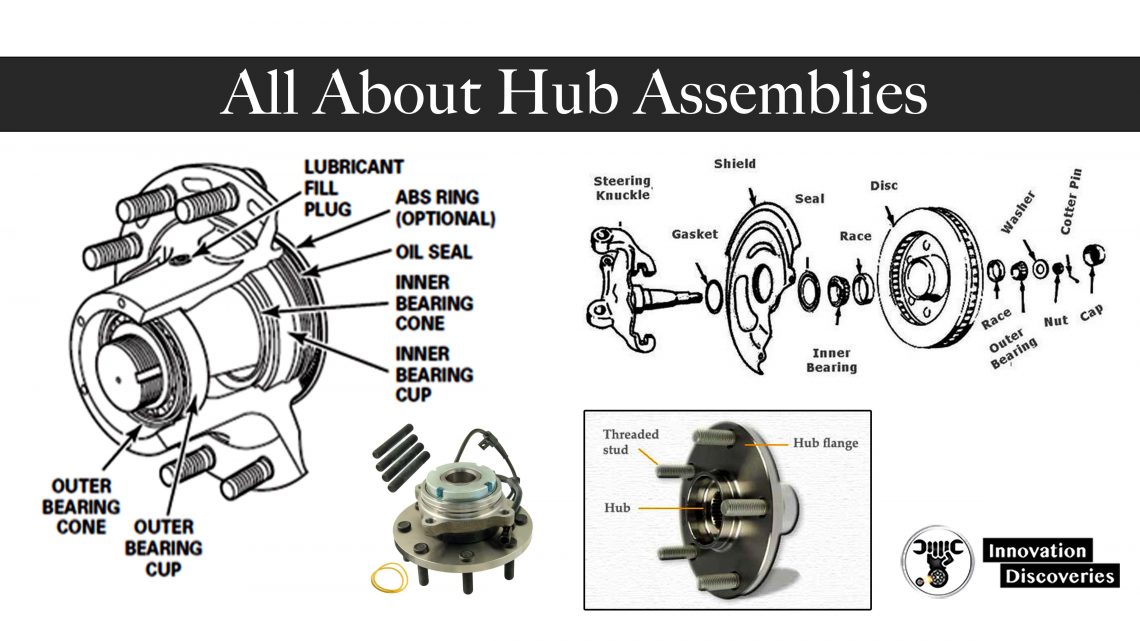

A hub assembly, also known as a wheel hub assembly, is a compact yet complex unit that comprises several vital parts working together to facilitate wheel movement and vehicle control.

It acts as a link between the wheel, tire, and the vehicle’s suspension system. Essentially, it allows the wheel to rotate freely while providing a secure attachment point for the brake components.

Construction and Components

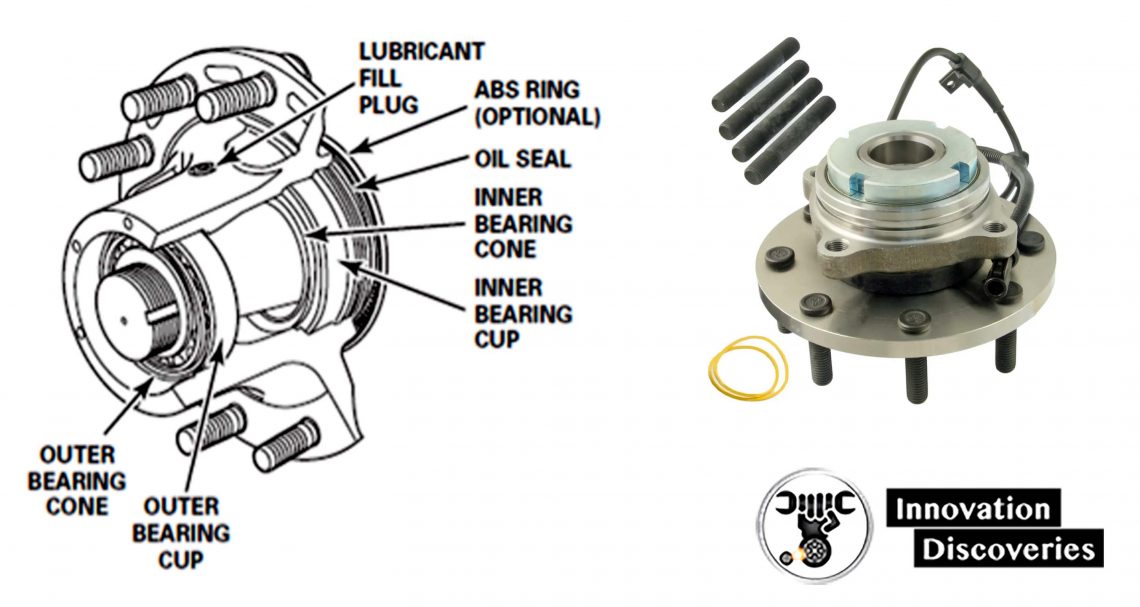

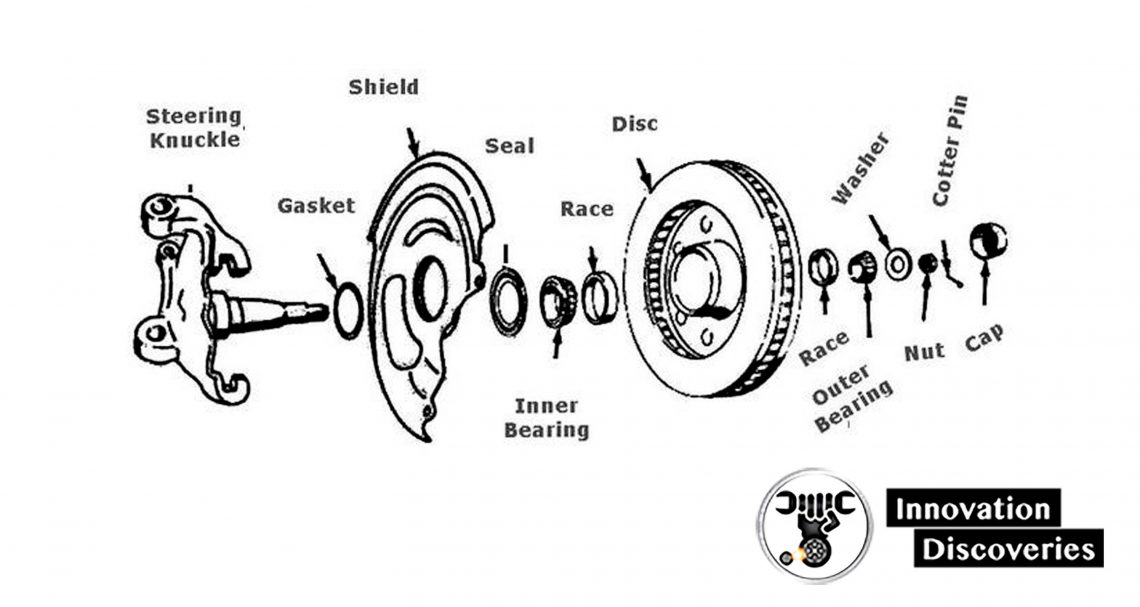

Hub assemblies are meticulously designed to handle the rigors of road travel. The primary components of a hub assembly include:

1. Hub:

The central component that holds the wheel and connects it to the axle. It’s designed to withstand the vertical and lateral forces exerted during acceleration, braking, and turning.

2. Bearing:

Bearings within the hub assembly enable smooth rotation of the wheel. They reduce friction and heat generation, which are crucial to prevent premature wear and ensure optimal performance.

3. Seals:

These keep dirt, debris, water, and contaminants out of the hub assembly, protecting the bearings from damage. Seals also retain lubricants, extending the life of the bearings.

4. Flange:

The mounting point for the brake rotor or drum. It’s an integral part of the hub assembly, ensuring precise alignment and secure braking.

5. Bolts and Nuts:

These components hold the hub assembly securely to the vehicle’s suspension. Their proper torque is essential to prevent vibrations and maintain wheel alignment.

Importance of Hub Assemblies

Hub assemblies play a significant role in maintaining vehicle safety, stability, and performance:

1. Smooth Ride:

Properly functioning hub assemblies contribute to a smoother ride by enabling the wheels to rotate with minimal friction.

2. Vehicle Control:

The hub assembly’s connection between the wheel and suspension system directly impacts steering response, cornering stability, and overall vehicle control.

3. Braking Efficiency:

Hub assemblies play a crucial role in brake performance. Accurate alignment of the brake components ensures even contact between the brake pads and rotors, leading to efficient braking.

4. Reduced Wear:

High-quality bearings and effective seals in the hub assembly extend the lifespan of the wheel components, reducing the need for frequent replacements.

Maintenance and Replacement

Regular maintenance is key to preserving the integrity of hub assemblies:

1. Lubrication:

Adequate lubrication of bearings is crucial for minimizing friction and heat. Lack of lubrication can lead to premature wear and even catastrophic failure.

2. Seal Inspection:

Regularly check the seals for signs of damage or leakage. Damaged seals can allow contaminants to enter, leading to bearing failure.

3. Torque Check:

Ensure that the bolts and nuts holding the hub assembly are properly torqued. Loose fasteners can cause vibrations and misalignment.

4.Noise and Vibration:

Unusual noises or vibrations from the wheels could indicate problems with the hub assembly. Prompt inspection and action are essential.

Conclusion

While often overlooked, hub assemblies are indispensable components that directly influence a vehicle’s performance, safety, and longevity. As the unsung heroes of the automotive world, these assemblies ensure the smooth interaction of multiple systems, ultimately delivering a comfortable and secure driving experience.

Regular maintenance and timely replacement of worn components can significantly enhance the lifespan and functionality of hub assemblies, contributing to safer roads and happier drivers.

Visit Forum

Visit Our Friendly Website