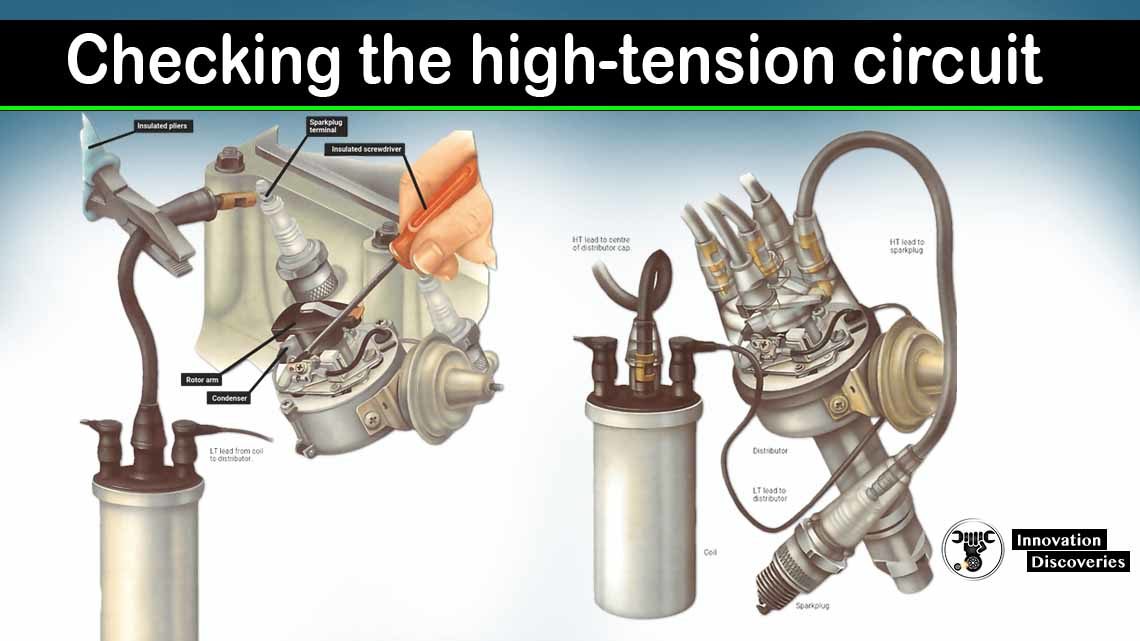

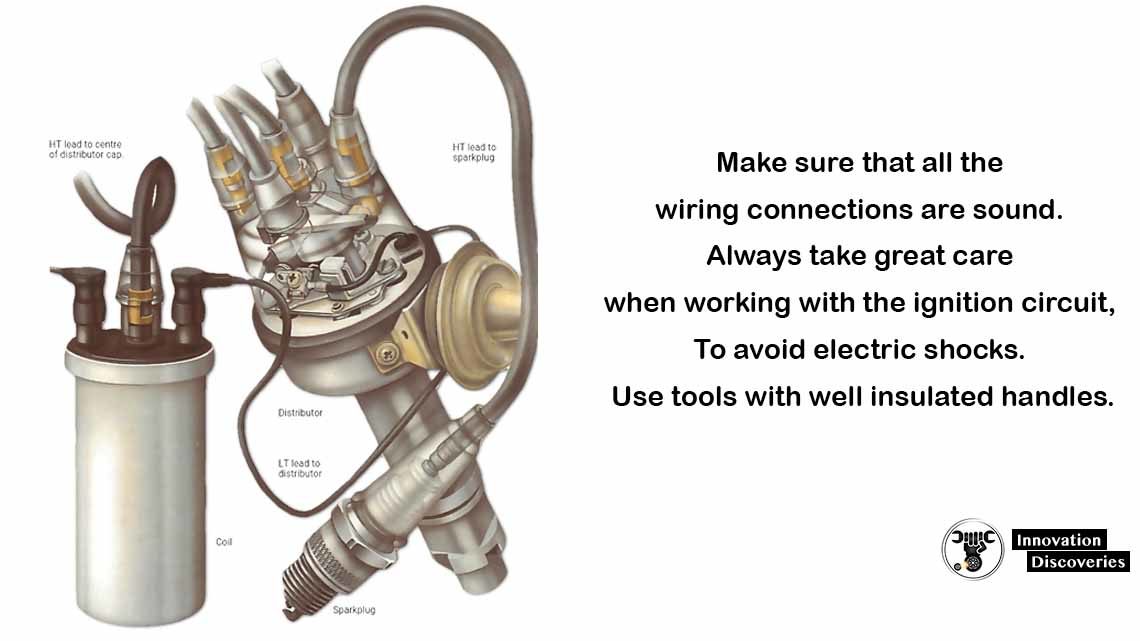

The high-tension (HT) or secondary circuit carries high-voltage electricity. It runs from the secondary coil of the coil through the distributor to the plugs. Any of those cans break down and cause ignition failure.

Do not touch any part of the HT circuit with bare hands when the ignition is switched on. Work with pliers and screwdrivers that have thickly insulated plastic handles. Lookout to not touch any metal parts of the tools.

Since HT-circuit checks involve using the car’s HT leads,

Begin by testing the results in confirm that they’re sound.

The high-tension (HT) circuit

Testing the coil secondary winding

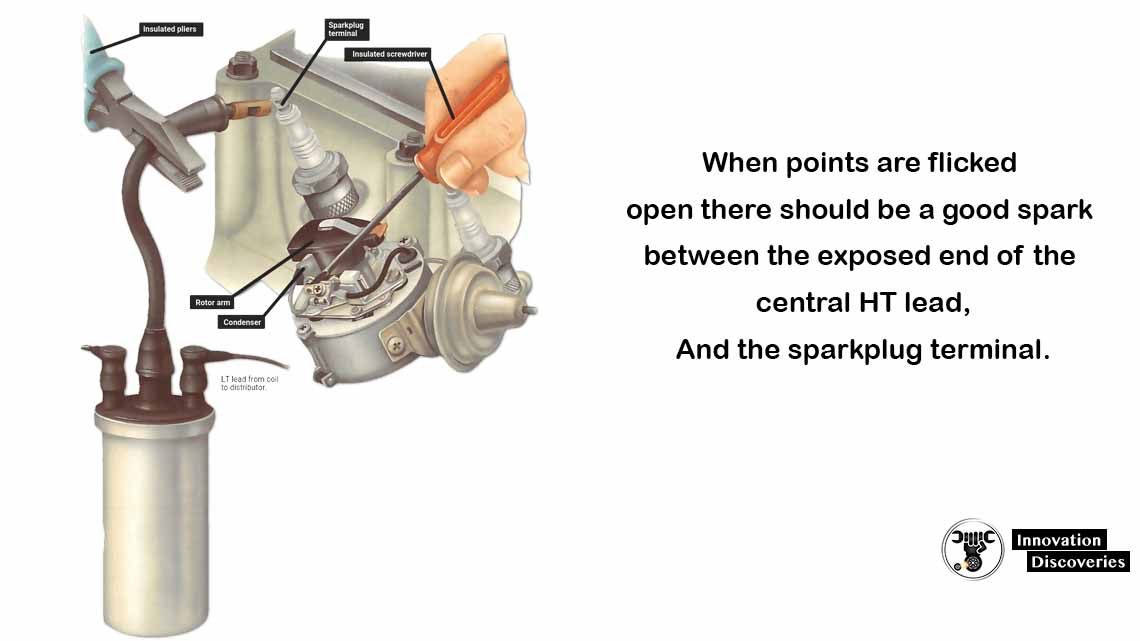

To check the secondary coil, begin the cap and detach the central HT lead.

Remove or keep off the lid from the top of the HT cause to expose the core connection.

Remove a lead from one among the spark plugs, then turn on the ignition.

Grip the detached central HT lead with insulated pliers, and hold its exposed end against the plug terminal. Flick open the contact-breaker points with a little insulated screwdriver.

A definite spark between the top of the HT lead and,

Therefore, the plug terminal shows that both the coil and condenser are so as.

An alternative test is often made by beginning ,

All the plug results in preventing the engine from starting

(Number the results in avoiding later confusion).

Remove one among the plugs and reconnect it to a lead. Touch it against the engine and await a robust spark when a helper turns the starter switch.

If either test produces only a weak spark, and therefore the HT leads are sound, suspect a faulty condenser. Check by fitting another condenser that you know to be serviceable.

Check the condenser connections. If the spark is not any better, or if the initial test gave no spark, the coil is faulty. Replace it if necessary.

It is possible for the rotor arm too short to the highest of the contact-breaker cam. Detach the central HT lead from the cap and hold it with insulated pliers. Turn on the ignition. Hold the exposed metal end of the point about in. (3mm) from the rotor-arm tip.

Flick the points open. There should be no spark or a feeble spark from static discharge. A robust spark means a short circuit.

Clean the cam and rotor arm of dirt and grease. If the difficulty persists, examine the rotor arm for cracks and replace it if necessary.

Click on Page 2 to read the rest of the article