Learning Objectives:

- Inspect the engine oil level and condition.

- Ensure that the lubrication system is working properly.

- Relationship between engine speed, oil temperature, and oil pressure.

Apparatus: Diesel Engine Test Bed

Theory:

An internal combustion engine would not run for even a few minutes if the moving parts were allowed to make metal-to-metal contact.

The heat generated due to the tremendous amounts of friction would melt the metals, leading to the destruction of the engine.

To prevent this, all moving parts ride on a thin film of oil that is pumped between all the moving parts of the engine. Once between the moving parts, the oil serves two purposes.

One purpose is to lubricate the bearing surfaces. The other purpose is to cool the bearings by absorbing the friction-generated heat.

The flow of oil to the moving parts is accomplished by the engine’s internal lubricating system.

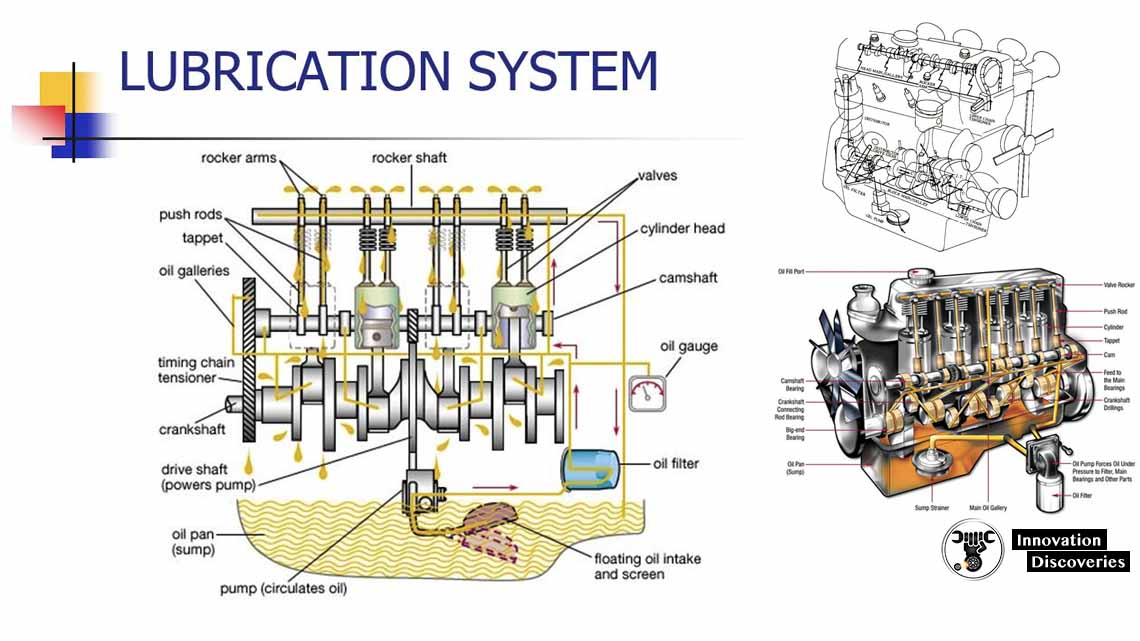

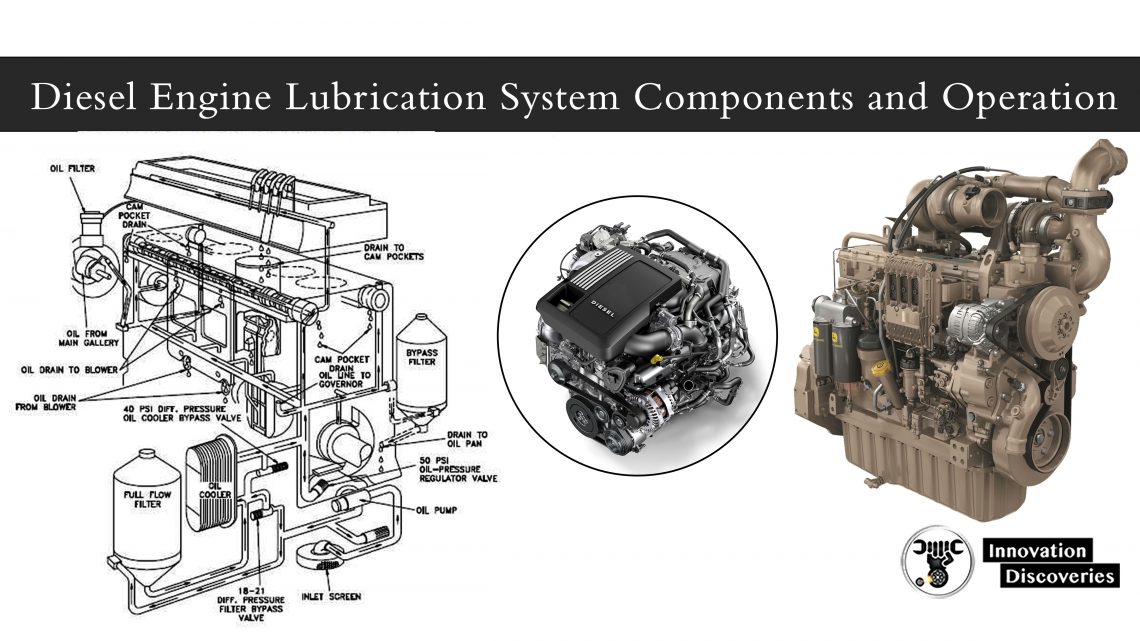

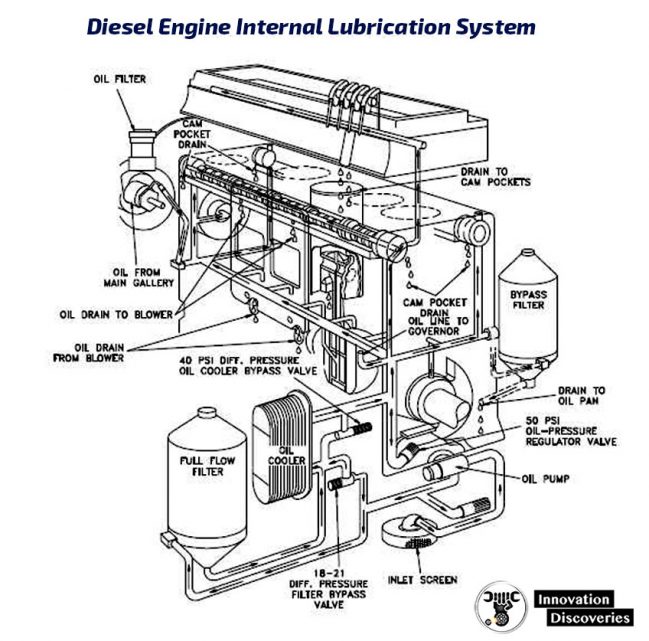

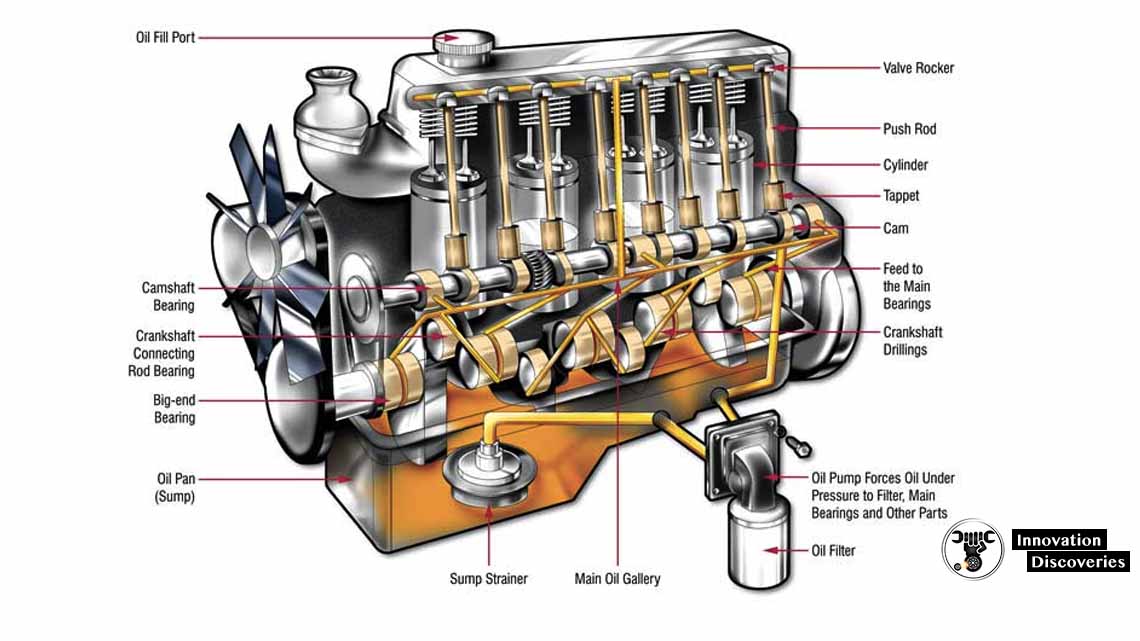

Oil is accumulated and stored in the engine’s oil pan where one or more oil pumps take suction and pump the oil through one or more oil filters as shown in Figure 1.

The filters clean the oil and remove any metal that the oil has picked up due to wear. The cleaned oil then flows up into the engine’s oil galleries.

A pressure relief valve(s) maintains oil pressure in the galleries and returns oil to the oil pan upon high pressure. The oil galleries distribute the oil to all the bearing surfaces in the engine.

Once the oil has cooled and lubricated the bearing surfaces, it flows out of the bearing and gravity flows back into the oil pan.

In a medium-to-large diesel engine, the oil is also cooled before being distributed into the block.

This is accomplished by either an internal or external oil cooler. The lubrication system also supplies oil to the engine’s governor.

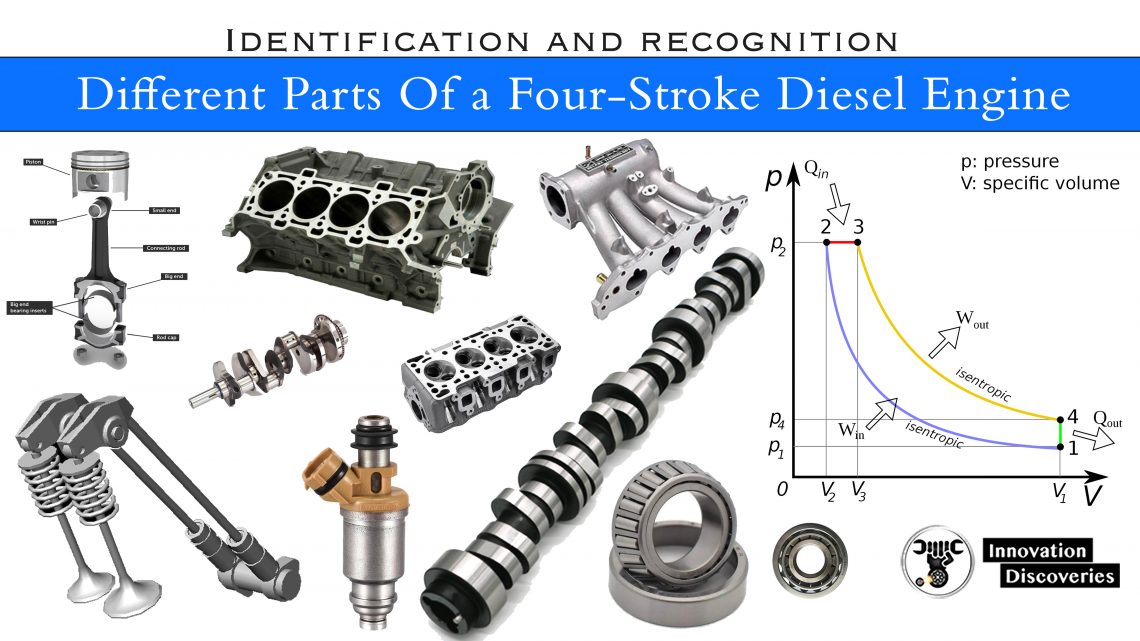

Parts of a diesel engine lubricating system

The main parts of the lube oil system are listed below:

- Oil Pumps

- Oil Filters

- Oil Cooler

- Oil manifold

- Oil Sump

The Oil pumps:

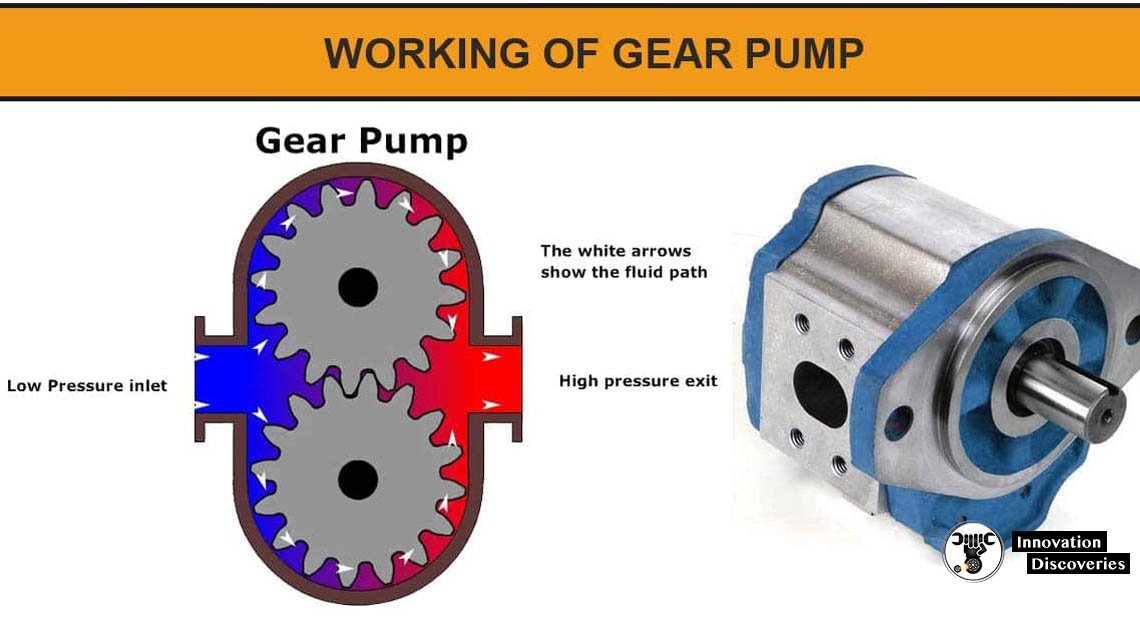

The engine-driven oil pump is usually a positive displacement gear-driven pump. It pulls oil from the lube oil pan (sump) and supplies it to the engine when the engine is running.

Pre-lube oil pump: In larger engines, the pre-lube pump is generally a close-coupled, self-priming, positive displacement pump of the rotary lobe or gear type.

Read More:

Oil filters:

The function of the filters is to clean the oil and remove any metal that the oil has picked up due to wear, and depending on its temperature, it may pass through the oil coolers or not before it goes to the engine bearing inside the engine through the oil main gallery inside the cylinder block.

Oil cooler:

The lube oil cooler assembly generally uses a shell and tube, heat exchanger. Depending on the lube oil flow rate, a single heat exchanger may be used or two or more units may be used.

The Oil manifold:

The oil galleries distribute the oil to all the bearing surfaces in the engine.

The Oil sump:

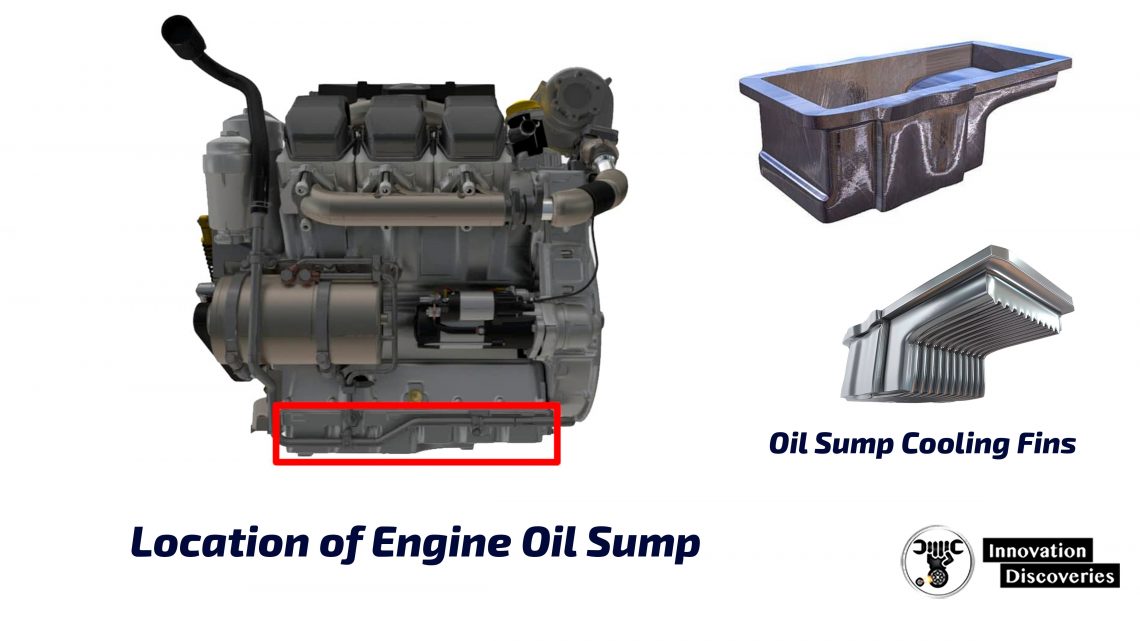

The oil sump is where the oil is accumulated and stored in the engine.

Discover More:

Visit Forum

Visit Our Friendly Website