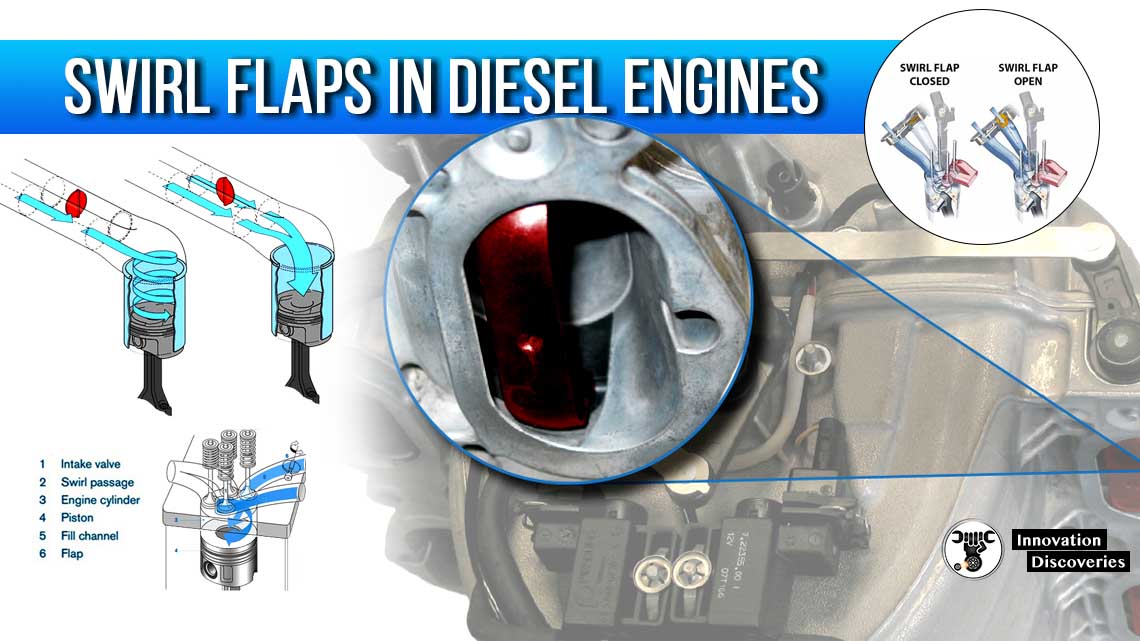

Swirl flaps produce a swirl alongside the cylinder axle. They are used in diesel vehicles to improve the mixing of the fuel-air mixture at low engine speeds.

For this purpose, the air is fed to each cylinder through two separate channels in the intake manifold. One of the two channels can be closed with a swirl flap.

Read:

- HOW DO GASOLINE ENGINES DIFFER FROM DIESEL ENGINES?

- WHY ARE DIESEL ENGINES USED IN HEAVY VEHICLES? EPIC REASONS

- TROUBLESHOOTING AND REPAIRING DIESEL ENGINE

This creates a swirling of the fresh air. Better mixing reduces fuel consumption and pollutant emission.

At higher engine speeds and torques, the swirl flap does open to achieve a better filling level.

The swirl flaps are also opened at starting of the engine and in overrun condition. Swirl flaps are also called “inlet duct cutoffs.”

In the Opel Twinport engine, the swirl flap reduces the throttle losses during part-load operation.

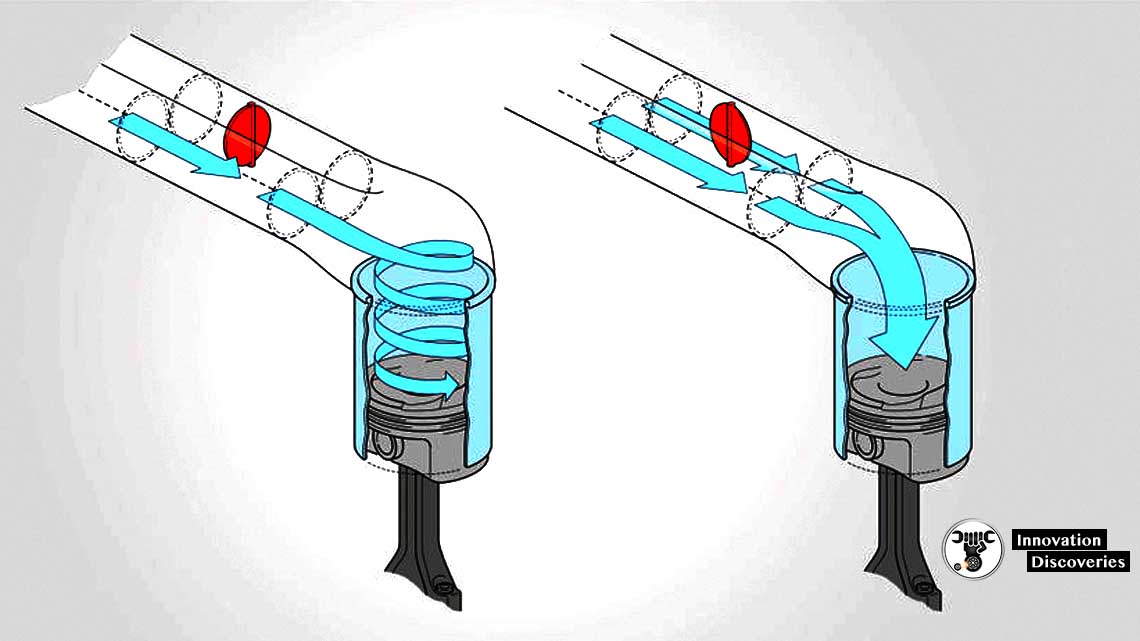

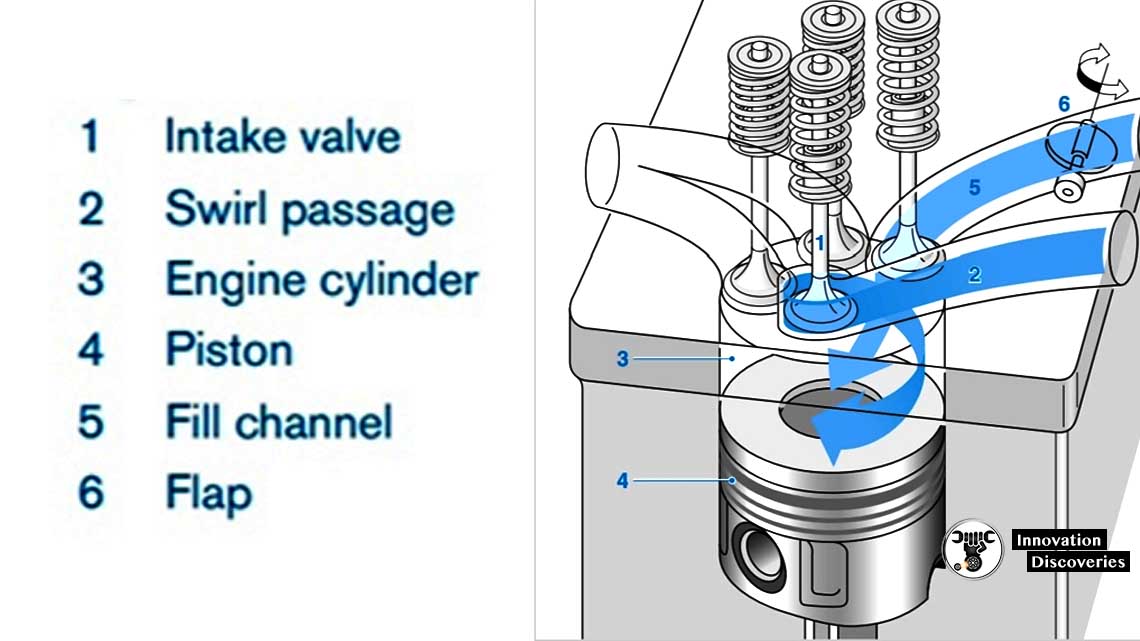

Left: part load, swirl flap closed, strong swirling

Right: full load, swirl flap open, high filling level

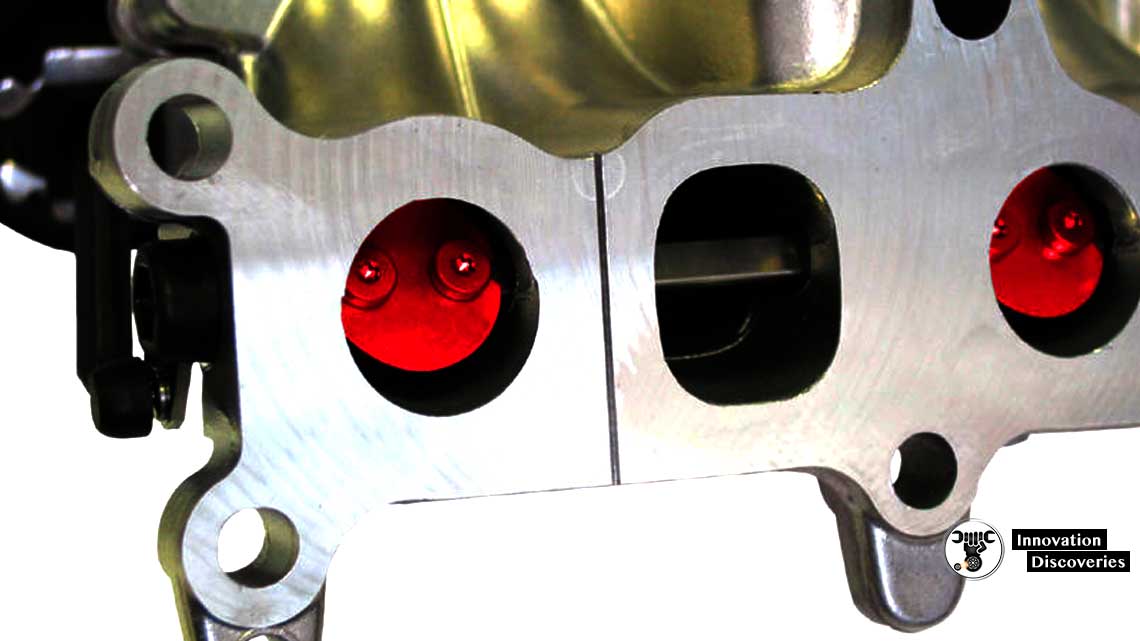

Two channels for each cylinder: Swirl flaps (highlighted in red) in the Pierburg intake manifold, e.g. in the Opel Astra J 1.7 CDTi

Abstract

The airflow pattern inside the cylinders of a diesel engine has a fundamental effect on mixture formation.

The factors that influence airflow pattern are:

- The airflow generated by injection jets

- The movement of air flowing into the cylinder

- Piston movement

Did You Know? | WONDERING “WHY ARE DIESEL ENGINES NOISY?” THE REASONS

The whirl-assisted air during the induction process helps in rapid mixture formation with the diesel fuel, which is critical for rapid combustion.

With the help of swirl flaps, whirl can be regulated depending on the engine speed and load.

The intake ducts are designed as fill channels and swirl passages to allow the passage for air.

The filling channel can be closed with the help of a flap (swirl flap), controlled by the engine management system.

The swirl flap is closed at low engine speeds (idling speed) and is fully open at high engine speed and load.

The flap can also be at an intermediate position depending on the engine speed. Swirl passages, on the other hand, don’t employ any flap.

At low engine speeds, the air does suck via the swirling passage. The whirl is much stronger as the fill channel is closed.

The filling channel does open at high engine speeds, allowing for more air quantity to be inducted into the cylinder. The whirl is not strong when flaps are open.

The control over whirl function makes it possible to cut the NOx and particulate emissions significantly, especially at low engine speeds.

Swirl flaps are used in some car engines and are playing an important role in minimizing emissions.

However, modern-day trucks have diesel engines that operate at low whirl rates.

Due to their smaller engine speed range and larger combustion chamber, the injection jets are sufficient to allow mixture formation.

Read More:

- PROFESSIONAL TIPS ON HOW TO START A FLOODED ENGINE

- HOW OFTEN TO CHANGE AIR FILTER IN CAR? THE ANSWER

- 3 INTAKE MANIFOLD LEAK SYMPTOMS (AND REPLACEMENT COST)

- WHAT ARE THE INTAKE MANIFOLD GASKET LEAK SYMPTOMS?

- INTRODUCTION OF ENGINES

- Piston and Piston Rings

Read More:

Visit Our Friendly Website