Introduction:

Diesel engines are renowned for their characteristic noise, which sets them apart from their gasoline counterparts. The distinctive sound emitted by diesel engines is a result of several factors contributing to their noisy operation.

In this discussion, we will delve into the major reasons behind the noise emissions of diesel engines.

Why Are Diesel Engines Noisy – The Major Reasons

Diesel engines have gained recognition for their distinctively loud noise, surpassing the sound levels typically associated with gasoline engines. The noisy operation of diesel engines can be attributed to a multitude of factors.

Let’s explore the major reasons behind their noise emissions:

1. Vibrations Inside The Engine-Inner Surface

One of the significant reasons for the noise produced by diesel engines is the vibrations that occur within the engine’s inner surface. Diesel engines operate under high compression ratios, which means that the air-fuel mixture is compressed to a greater extent before combustion.

This high compression leads to increased pressure and force during the combustion process. As the fuel ignites and expands rapidly, it exerts strong forces on the engine’s components.

These forces generate vibrations that propagate throughout the engine, resulting in the characteristic noise associated with diesel engines.

The vibrations inside the engine are amplified by the structure and materials used in its construction. The metal components, such as the engine block, cylinder head, and pistons, can act as resonators, amplifying the vibrations and creating more noise.

Additionally, the design of the engine, including the arrangement of cylinders and the firing sequence, can also contribute to the vibrations and subsequent noise production.

While efforts have been made to dampen these vibrations with improved engine design and the use of vibration-damping materials, diesel engines inherently produce more noise due to their high compression ignition process.

2. Combustion And Pressure

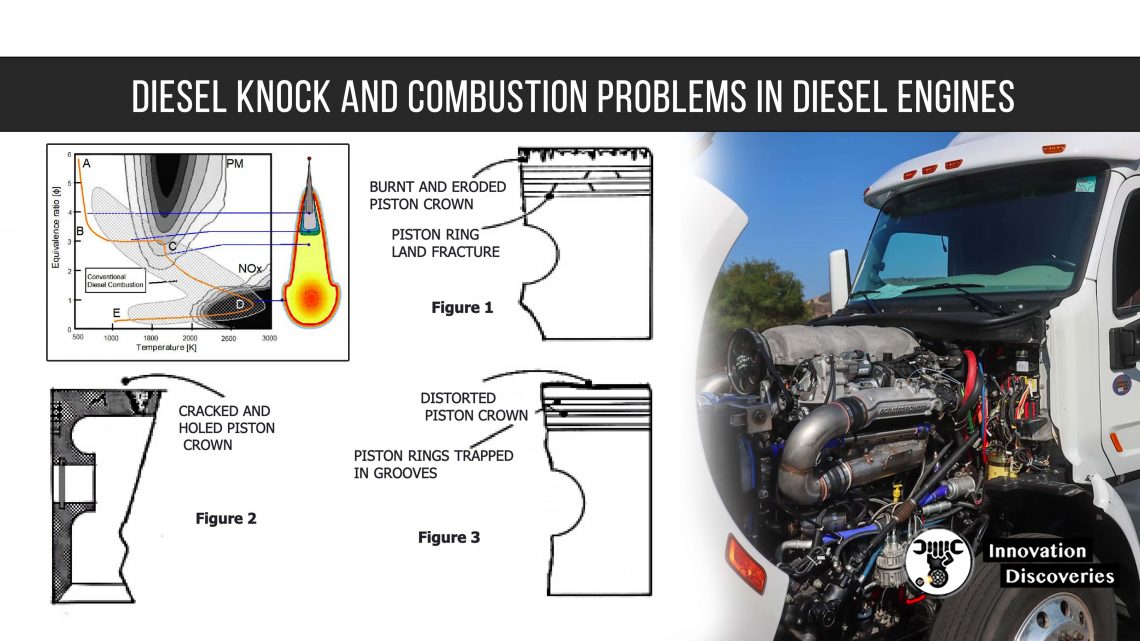

Unlike gasoline engines, which use spark ignition, diesel engines rely on compression ignition. This means that the air-fuel mixture in a diesel engine ignites due to the high pressure and temperature resulting from the compression of air within the combustion chamber.

When the fuel is injected into the combustion chamber and comes into contact with the hot, highly compressed air, it rapidly combusts, creating a powerful release of energy.

This combustion process generates a distinctive knocking or clattering sound that is characteristic of diesel engines.

The rapid expansion of gases during combustion further adds to the noise level. As the fuel ignites and the gases rapidly expand, the resulting pressure and force exerted on the engine components and the surrounding air cause vibrations and sound waves to propagate.

These sound waves contribute to the overall noise emitted by the engine. Additionally, factors such as fuel quality, injection timing, and combustion efficiency can also influence the noise produced during the combustion process.

While advancements in engine technology and fuel injection systems have helped reduce this noise, it remains a characteristic feature of diesel engines due to their unique combustion process.

3. Vibrations Of Surface & Accessories- Outer Surface

Apart from the vibrations occurring within the engine’s inner components, diesel engines also generate noise due to vibrations on their outer surfaces. Various engine accessories, such as fuel injectors, pumps, and valves, undergo mechanical oscillations during operation.

These vibrations can be caused by the reciprocating motion of pistons, the movement of valves opening and closing, or the rotating motion of engine components.

These mechanical oscillations transfer to the engine’s outer surfaces, leading to additional noise generation.

The vibrations of surface and accessories are often amplified by the engine’s housing and other surrounding components. The engine block, cylinder head, and other parts act as resonating chambers, amplifying the vibrations and producing more audible noise.

Additionally, the materials used in the engine’s construction can impact the noise generated. Certain metals or alloys may have natural resonance frequencies that coincide with the vibrations produced, resulting in increased noise levels.

Efforts to mitigate these vibrations include using vibration-damping materials, optimizing the design of engine accessories, and implementing better insulation techniques.

4. Size Of Engine Parts

The size and design of engine parts also contribute to the noise emissions of diesel engines. Diesel engines generally have larger and heavier components compared to gasoline engines.

Components such as pistons, crankshafts, and connecting rods are more substantial in diesel engines due to the higher compression ratios and greater forces involved in the combustion process.

These larger parts have more mass and are subjected to stronger forces during operation, leading to louder vibrations and subsequently increased noise levels.

The mechanical movements of these larger engine parts generate significant vibrations within the engine. As these vibrations propagate through the engine’s structure, they contribute to the overall noise output.

Additionally, the design and geometry of the engine parts can influence the noise generated. Complex shapes or structures that are prone to resonance or vibration amplification can result in higher noise levels.

Engine manufacturers employ various techniques such as optimizing component sizes, utilizing vibration-damping materials, and employing advanced manufacturing processes to minimize the noise produced by larger engine parts.

Conclusion

In conclusion, diesel engines are known for their distinctive noise, which is often louder compared to gasoline engines. Several factors contribute to the noisy operation of diesel engines. Vibrations occurring within the engine’s inner components, such as the result of high compression ratios and intense forces during combustion, play a significant role in the noise emissions.

The combustion process itself, driven by compression ignition, leads to rapid energy release and creates knocking or clattering sounds. Vibrations on the outer surfaces caused by mechanical oscillations of accessories and engine components further contribute to the overall noise level.

Additionally, the size and design of engine parts, including larger and heavier components, generate more noise due to their mass and the forces acting upon them. These factors combine to make diesel engines inherently noisier compared to gasoline engines.

While advancements in technology and engineering have aimed to reduce diesel engine noise, the fundamental characteristics of diesel combustion and the mechanical nature of these engines continue to contribute to their distinctive and often louder noise emissions.

Discover More:

Visit Forum

Visit Our Friendly Website

6 Comments