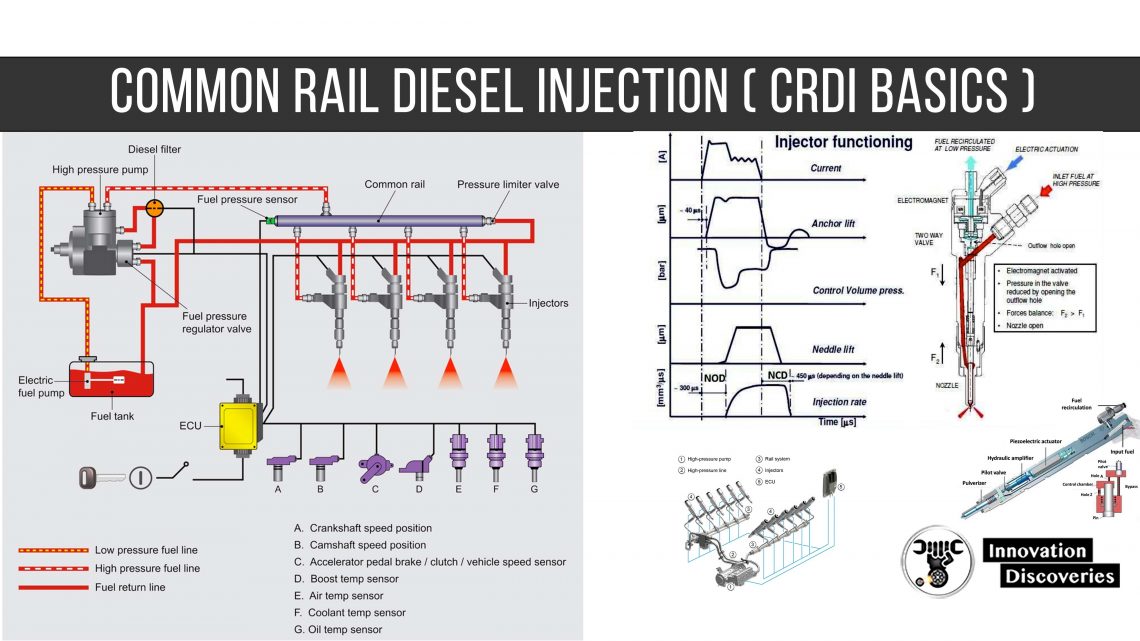

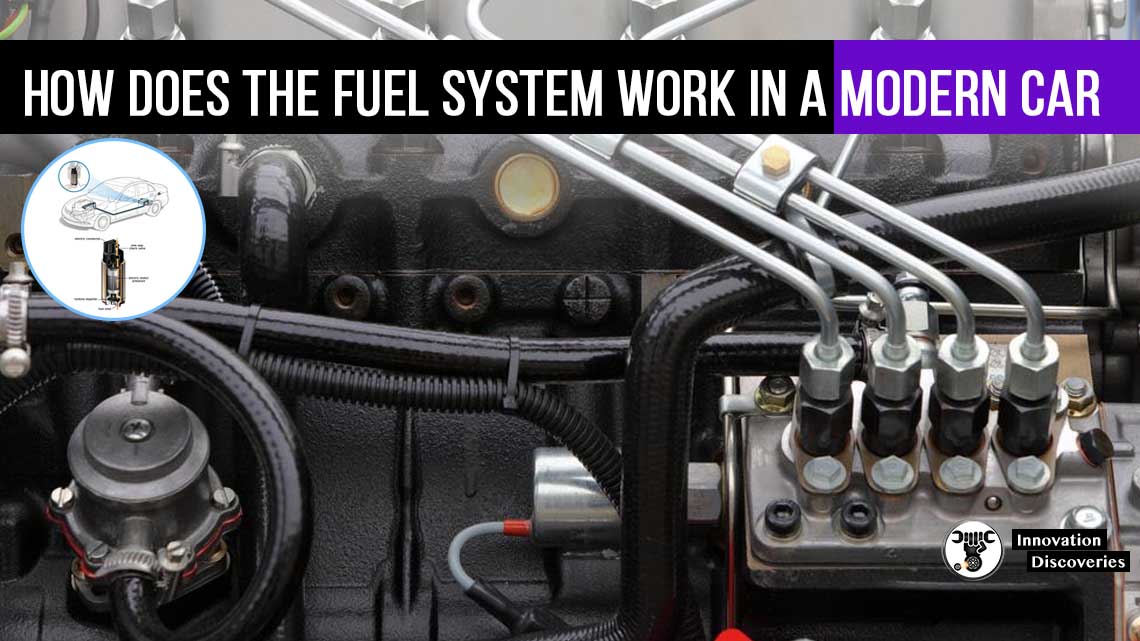

Satisfactory combustion of diesel fuel requires extremely fine atomisation of the fuel and precise regulation of the start and finish timing of the injection period.

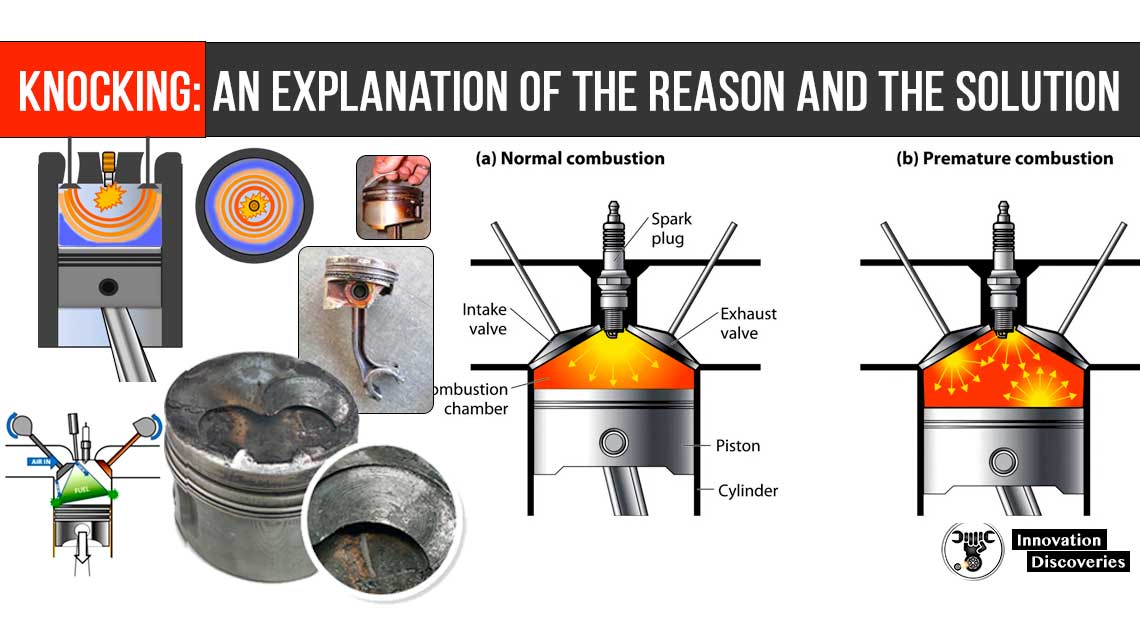

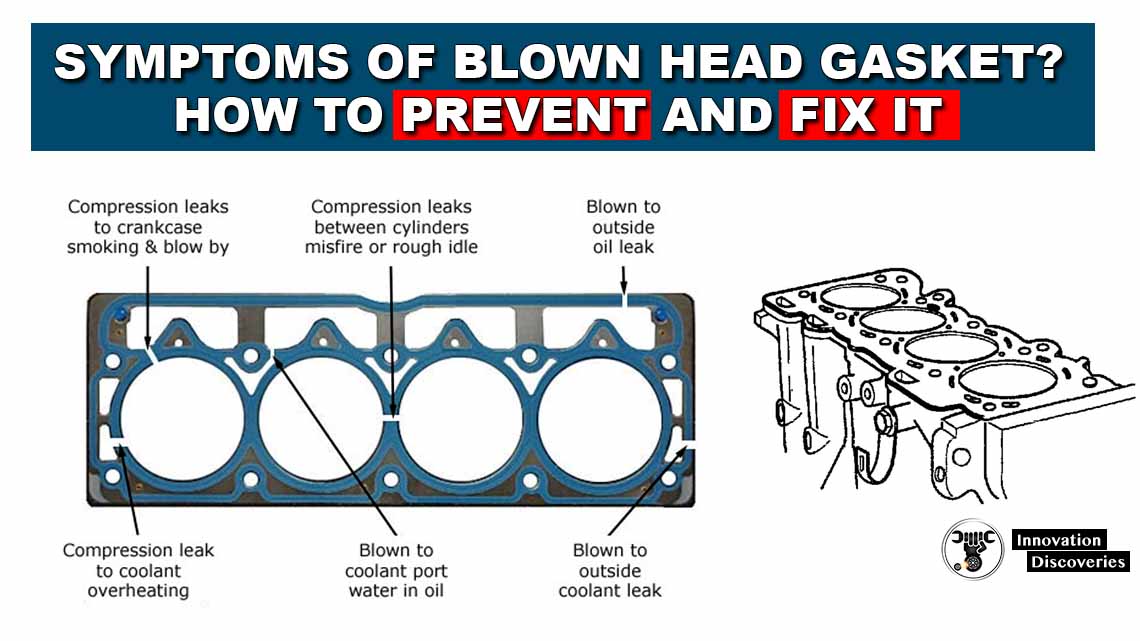

The normal pressure cycle of diesel combustion can be adversely affected by a range of influences, three of which are particularly notable:

- Ignition delay

- Incomplete combustion

- Leaking injectors

The injected liquid fuel droplets must reach distillation temperature and vaporize before ignition occurs.

This requires a time delay between the points of injection and ignition.

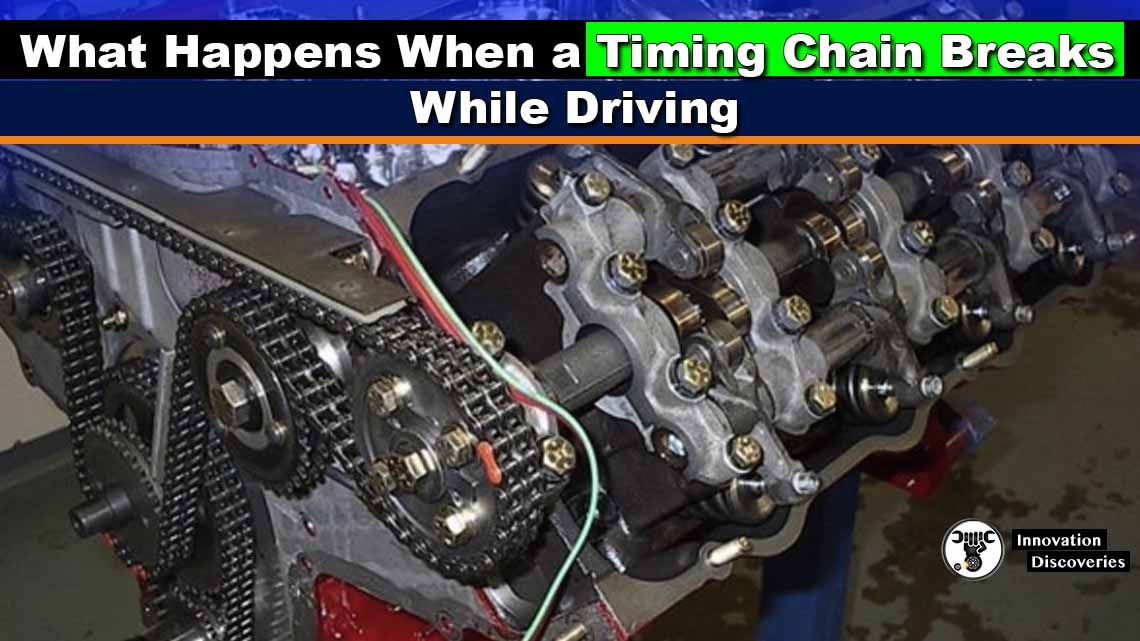

If the commencement of ignition is further delayed for any reason, then there is an increase in the volume of uncombusted fuel in the combustion chamber, and when ignition does occur, the result is a rough running engine (known as “diesel knock”).

If this condition continues, engine component overload and failure are likely.

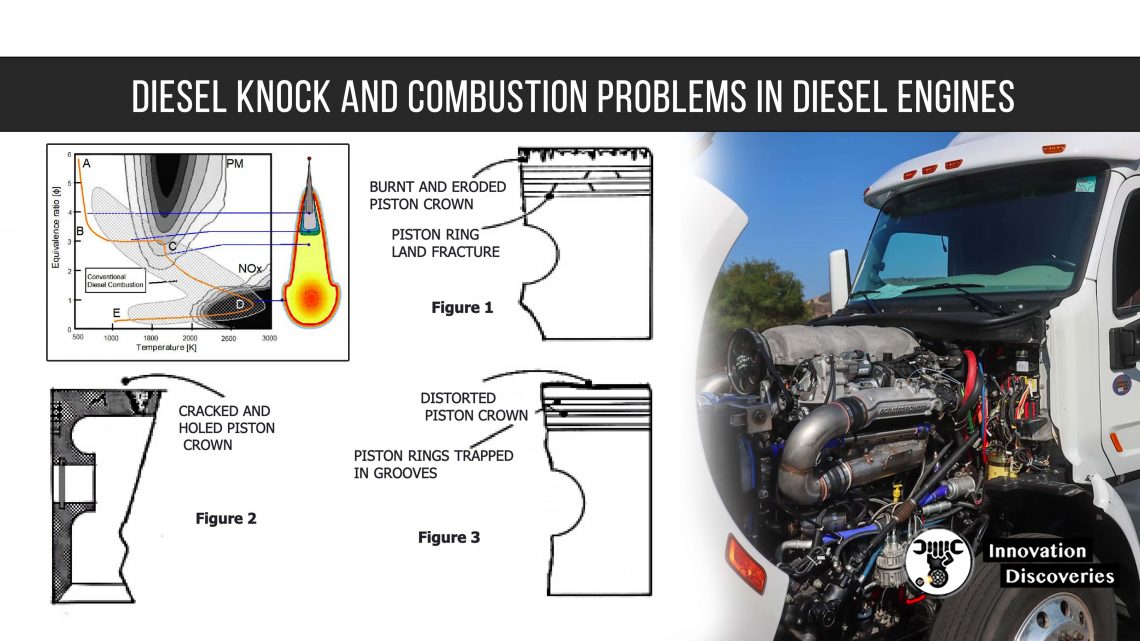

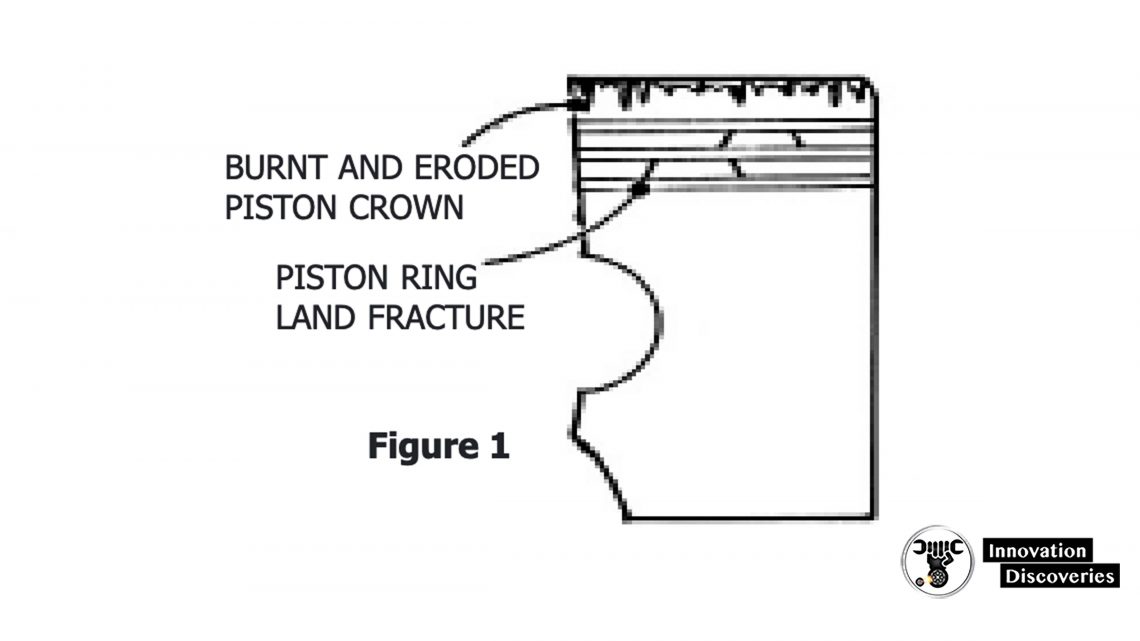

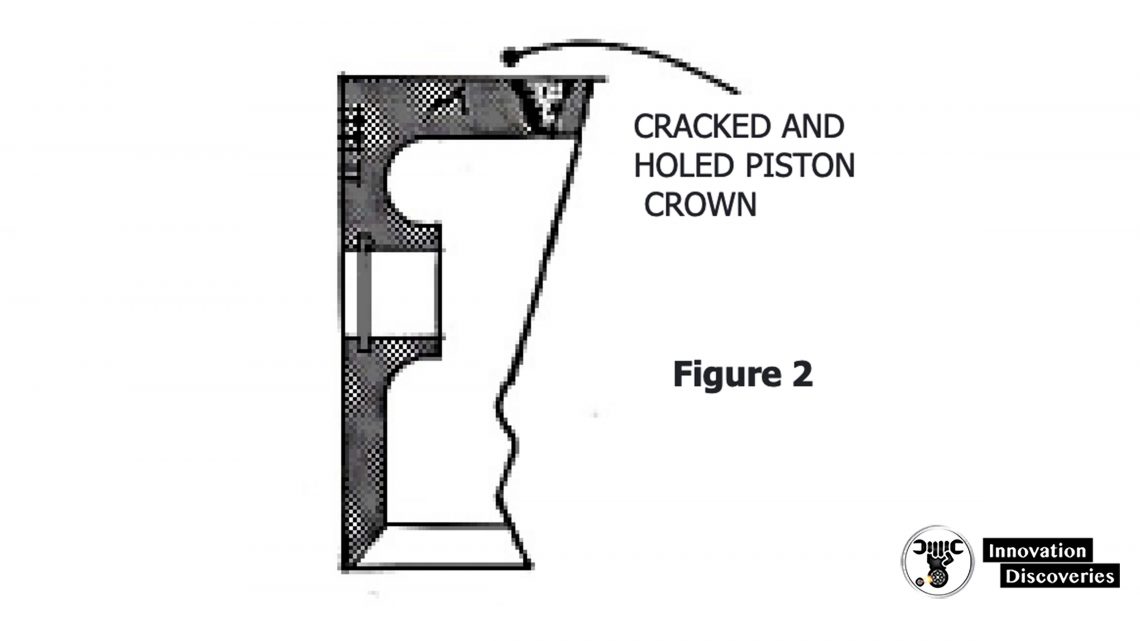

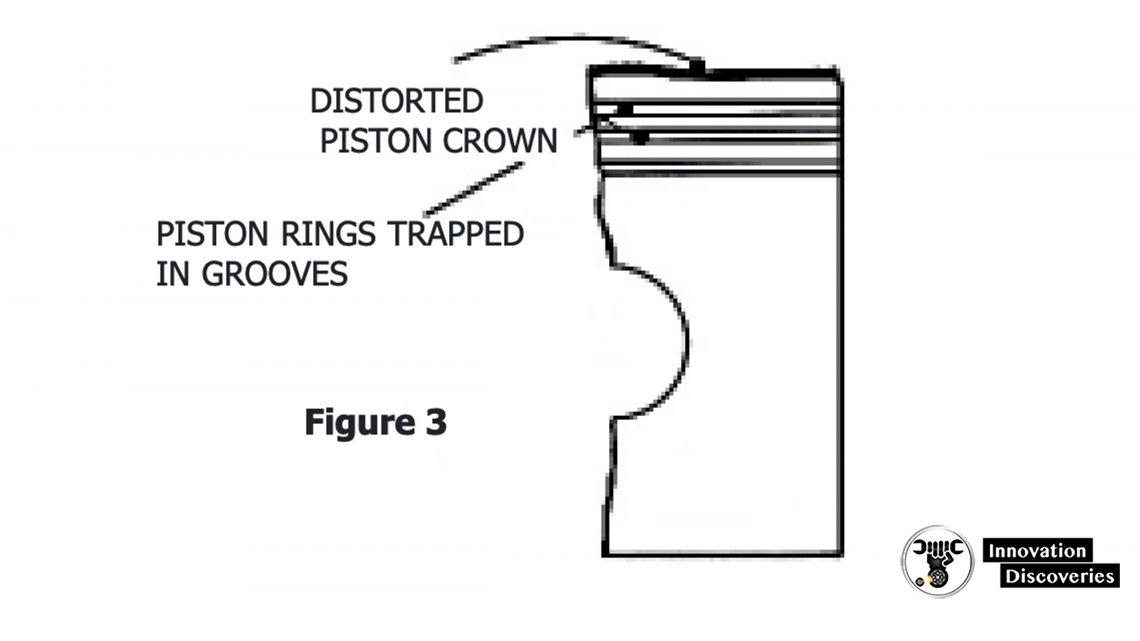

This could include piston crown and ring land fractures (Figures 1, 2, and 3).

There are six primary factors influencing ignition delay:

- Injected fuel droplet size and velocity

- Engine compression ratio/cylinder pressure

- Fuel grade – cetane rating and vaporisation point

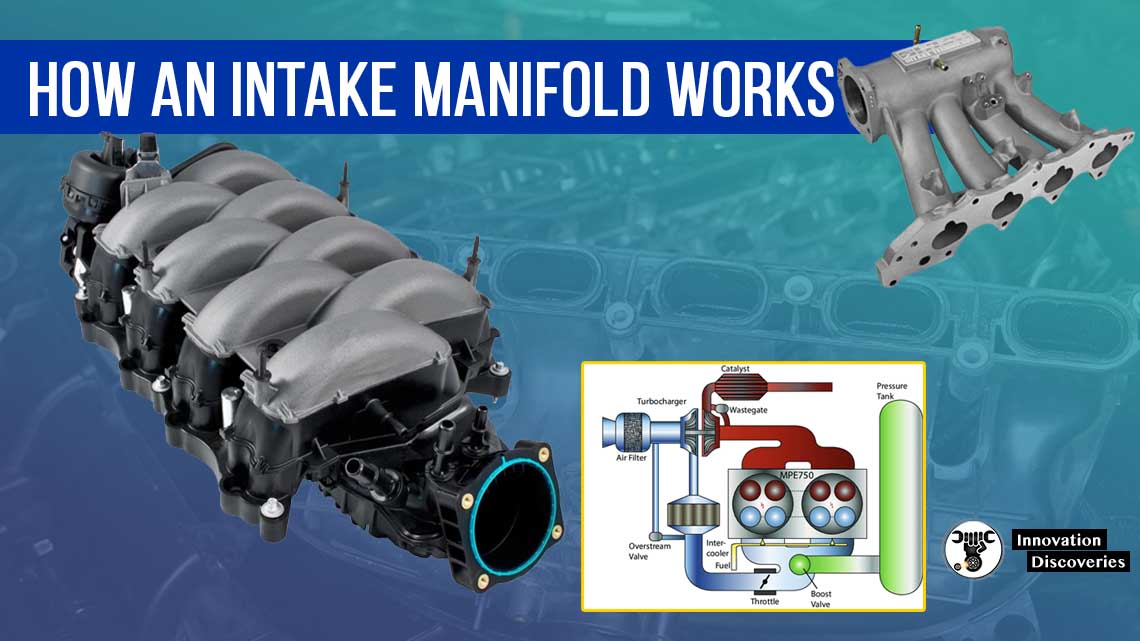

- Intake air temperature, pressure and volume

- Ignition timing – advanced or retarded

- Engine temperature

Incomplete combustion is typically one of the results of ignition delay, and each of the above factors applies.

Unburned or incompletely burned fuel condenses on the cylinder walls and piston crowns.

When it impinges on the cylinder walls, the lubrication film is weakened or destroyed.

The ring surfaces and cylinder walls then start to overheat, resulting in excessive wear or scuffing of ring faces and flanks, piston groove flanks, cylinder surfaces and ultimately ring lands and piston skirts.

If for any reason the injector delivers an anatomized stream of fuel to the cylinder, then piston crown burning, erosion, and melting are the likely outcomes (Figures 1 and 2).

Adverse effects of abnormal combustion include:

- Excessively noisy engine (diesel knock)

- Smoking engine – white or black

- Thermal stress cracks in piston crowns (Figure 2)

- Ring land distortion or fracture (Figures 1 & 3)

- Piston crown distortion, fracture, burning, erosion or melting

- Ring land and piston skirt scuffing

Discover More:

Visit Forum

Visit Our Friendly Website