After reading this article, you will be able to understand:

- All the parts of the diesel engine.

- The working principle of a diesel engine.

- The operation of the diesel engine.

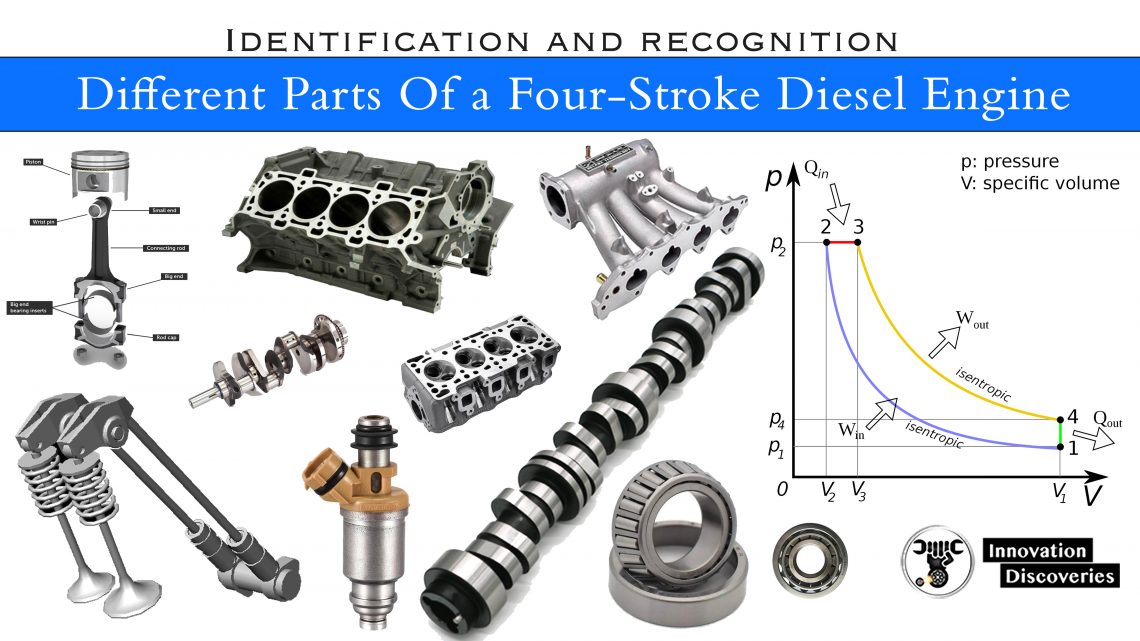

Main Parts

- Cylinder Block

- Piston

- Cylinder head

- Connecting rod

- Crankshaft

- Oil sump

- Camshaft

- Valves

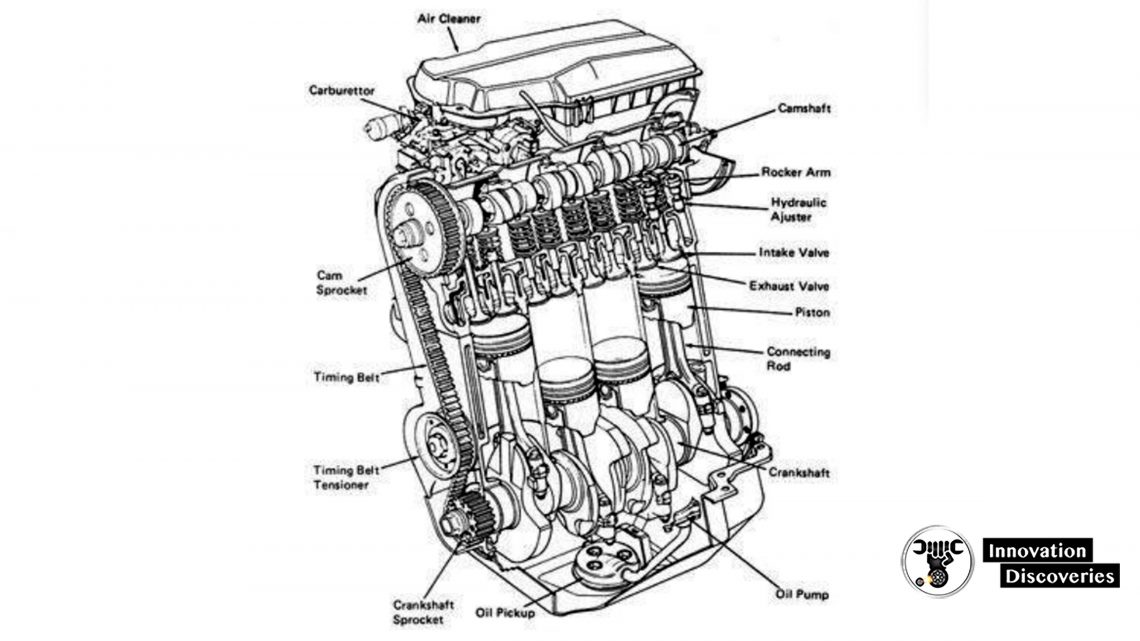

Labelled Diagram of a 4-Stroke Diesel Engine

Description of main parts

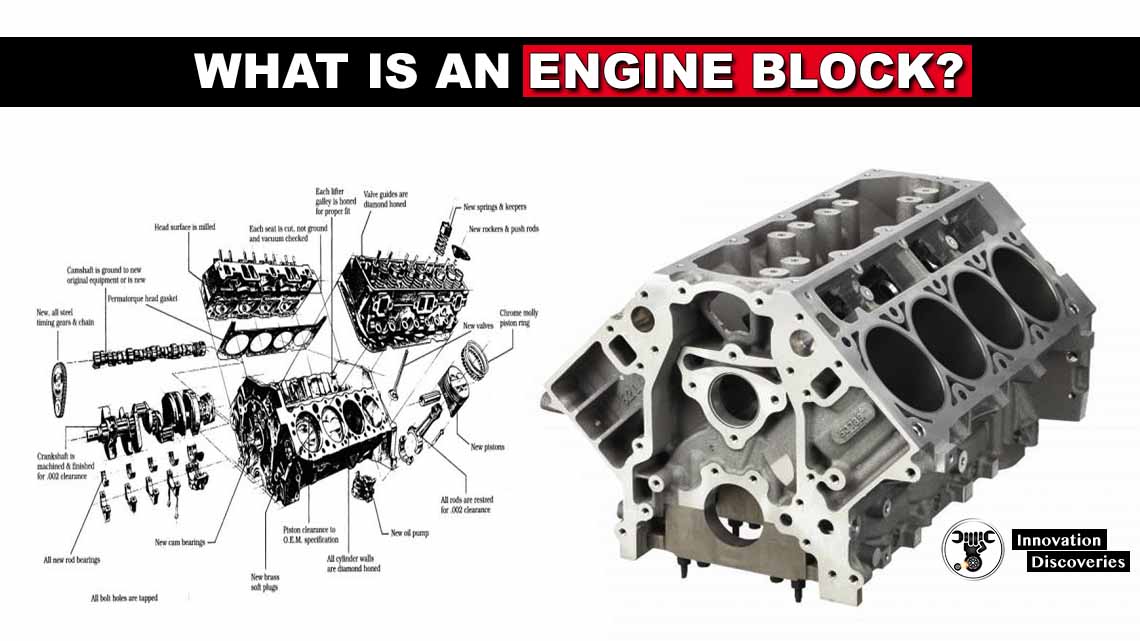

Cylinder block

The cylinder block or cylinder is the main part of an engine. It is a part in which the combustion of fuel takes place.

All other parts like piston, connecting rod, crankshaft, water jacket etc. are bolted on it.

Read More:

Piston

The piston is placed in the cylinder and transmits the thrust to the connecting rod. It is free to move.

Compresses the air-fuel mixture and converts the fuel energy into mechanical energy. It transmits the power to the crankshaft.

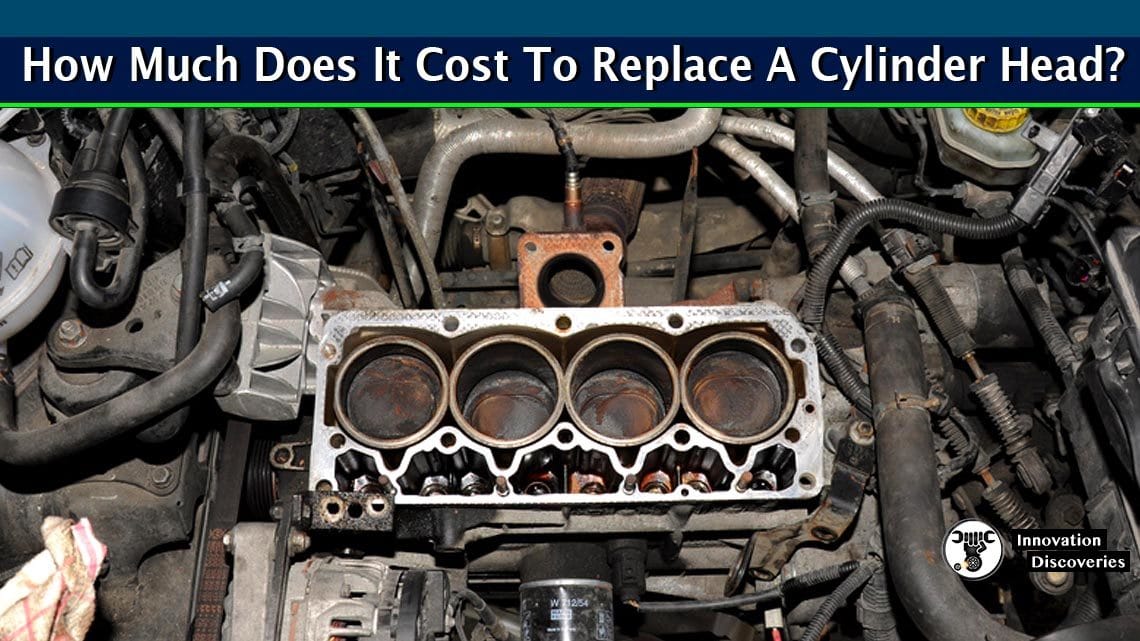

Cylinder Head

The cylinder head is fitted on the top of the cylinder block, and the function of the cylinder head is to seal the working end of the cylinder and not to permit entry and exit of gases on the cover head valves of the engine.

The valves, spark plug, camshaft, etc are fitted on it.

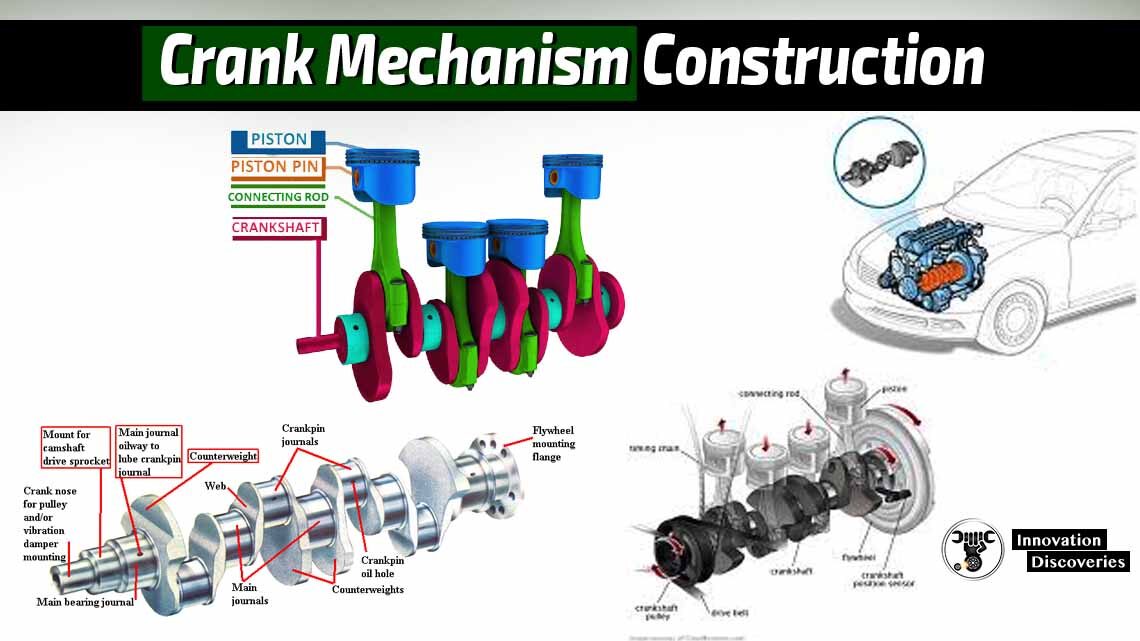

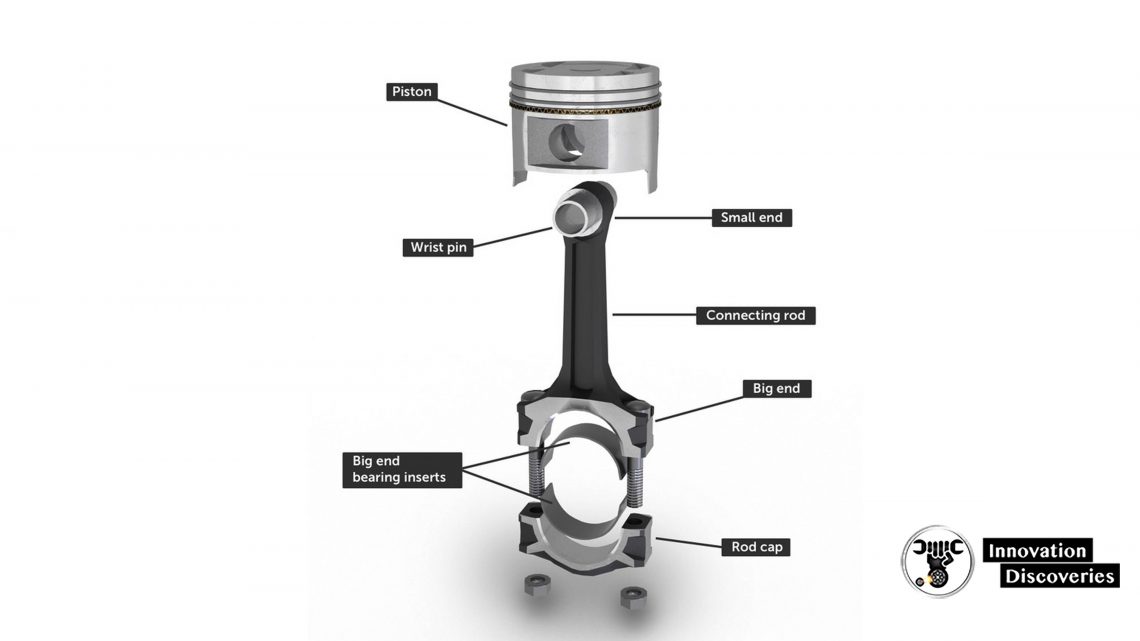

Connecting Rod

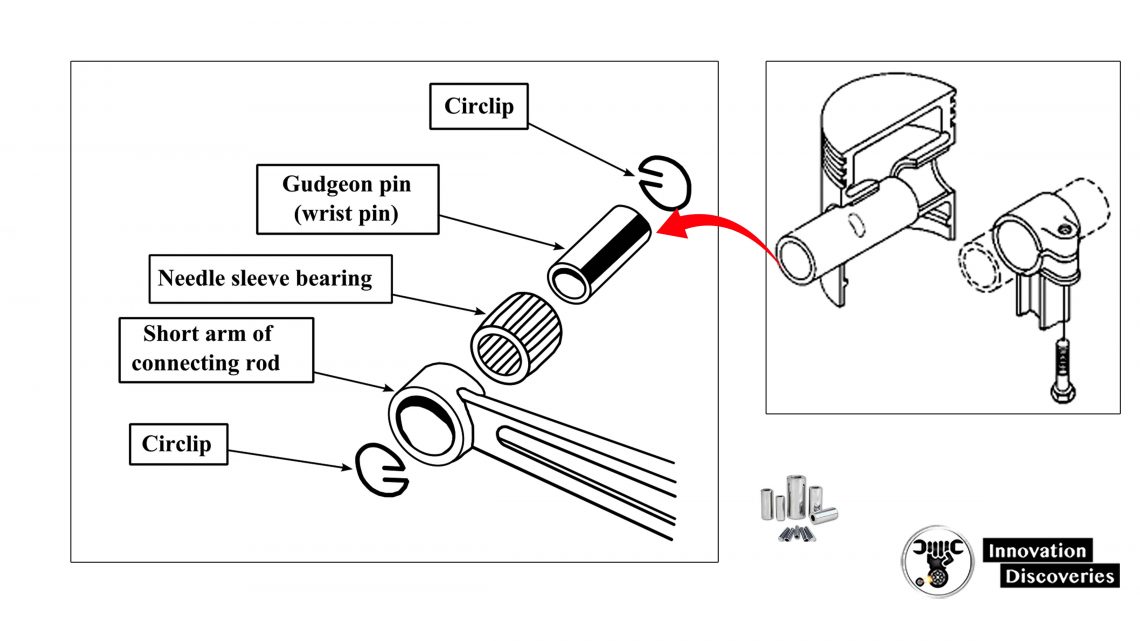

It connects the piston to the crankshaft and transmits the motion and thrust of the piston to the crankshaft.

The lower end of the connecting rod is connected to the piston and the bigger is connected to the crankshaft.

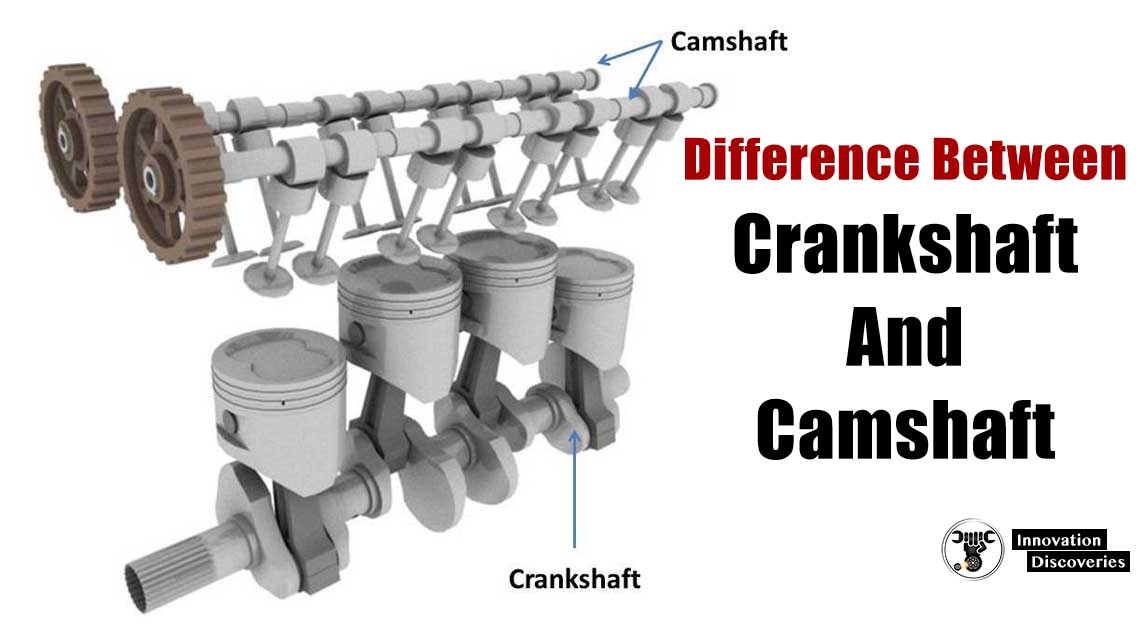

Crankshaft

It is located at the bottom end of the cylinder block. It transmits the reciprocating motion of the piston into rotary motion.

This rotary motion is used to rotate the wheels of the vehicle.

Oil Sump

It is bolted at the lower end of the cylinder block. All the oil for lubricating the movable parts is placed in it.

Camshaft

It is fitted either in the cylinder head or at the bottom of the cylinder

block. It is used to open or close valves at proper timing in a multi-cylinder engine.

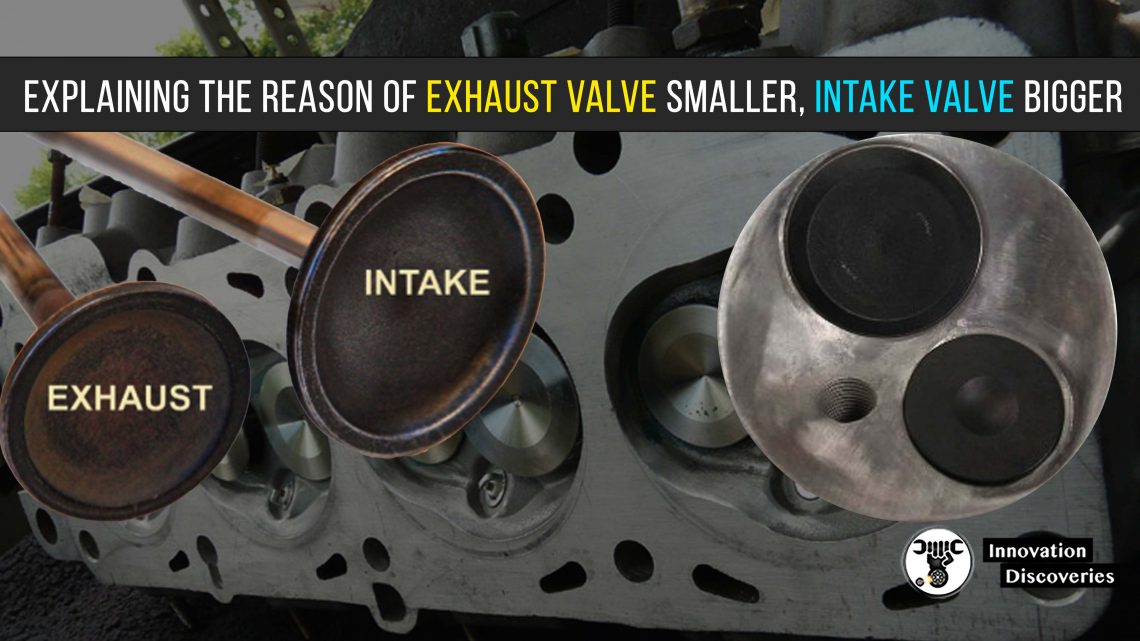

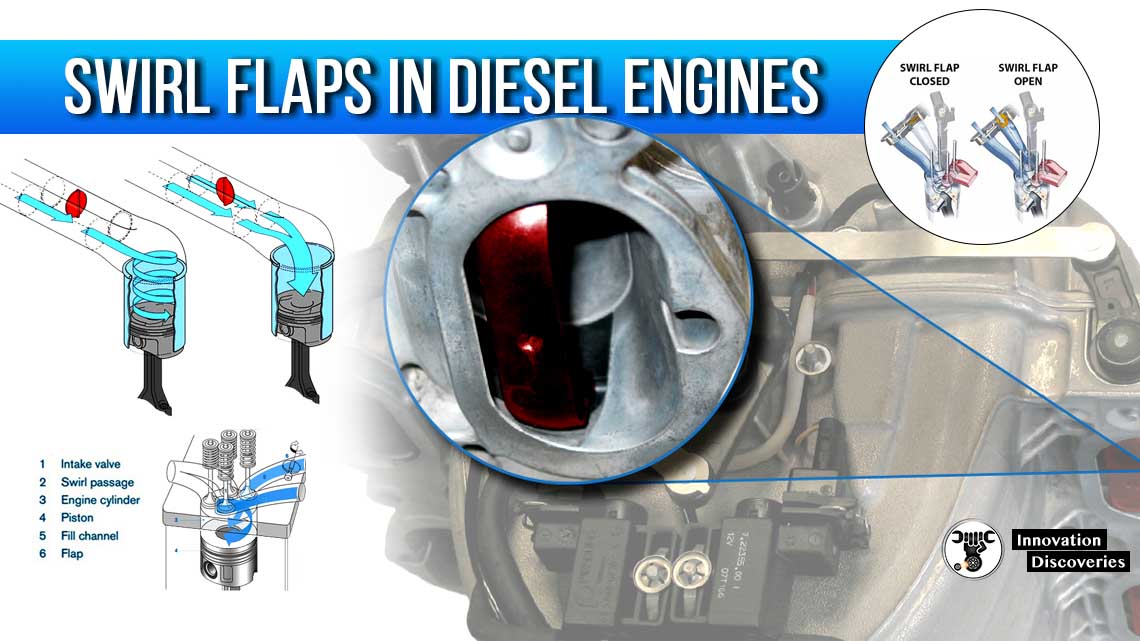

Valves

It is fitted on the cylinder head. It regulates the flow of air-fuel mixture inside the cylinder and exhaust gas outside the cylinder block.

When both inlet and exhaust valves are closed no pressure can go inside or outside of the cylinder block.

Spark Plug

It is used in the Petrol engine (Spark Ignition Engine). And it is fitted on the cylinder head. It is used to ignite the air-fuel mixture inside the cylinder at the end of each compression stroke.

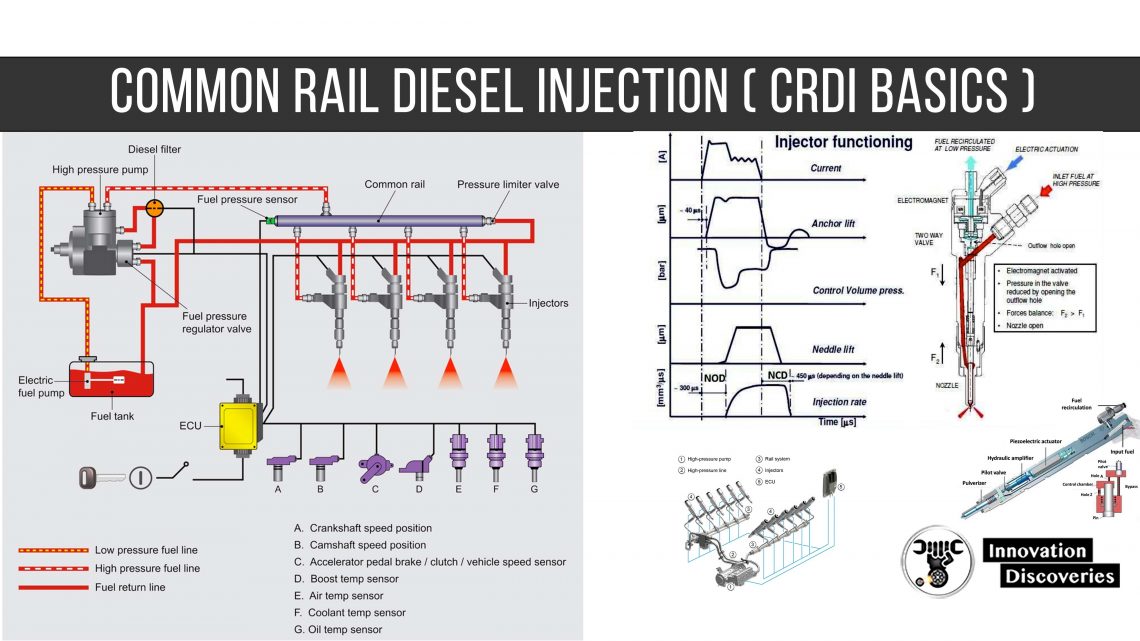

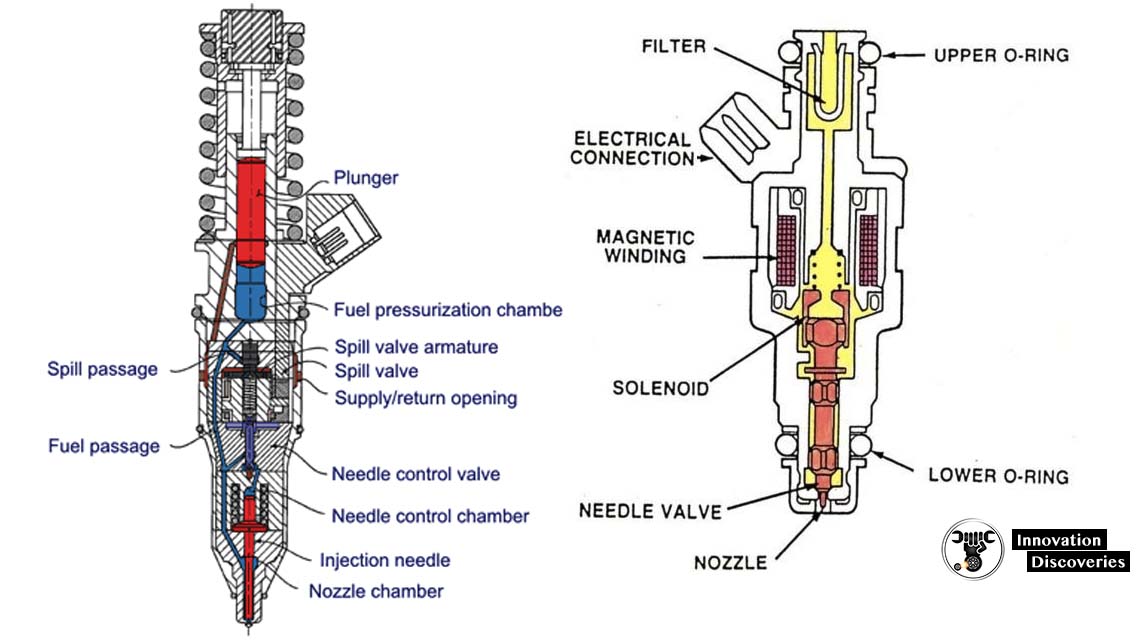

Injector

It is used in the diesel engine (compression ignition engine). And it is fitted on the cylinder head.

It is used to inject fuel in spray form inside the cylinder at the end of the compression stroke.

Read More: What is Automobile Injector and its Types

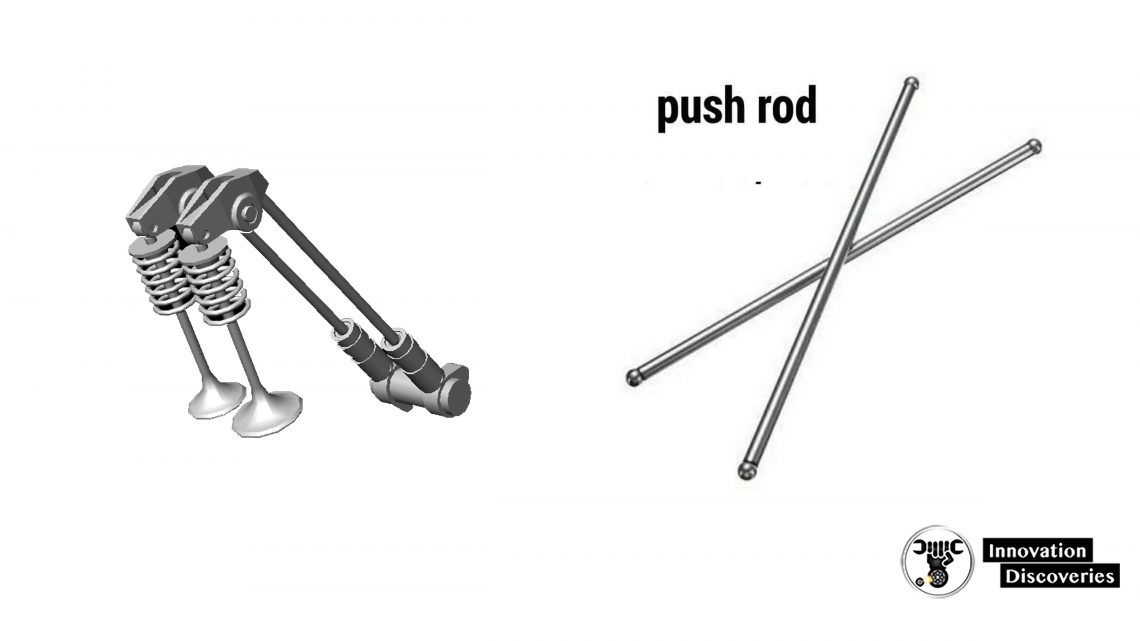

Push Rod

It is used when the camshaft is situated at the bottom of the cylinder head.

It regulates the timing of valves opening and closing through the rocker arm and camshaft.

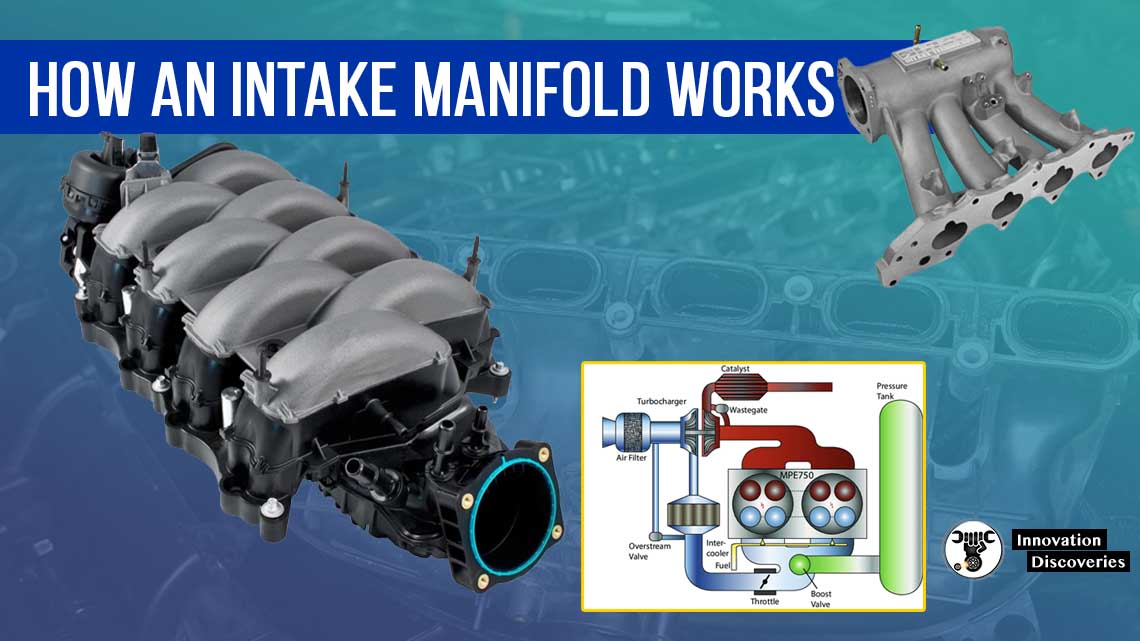

Manifold

It is bolted on the cylinder head, one each for intake and exhaust.

Its function is to evenly distribute the air-fuel mixture for intake and collect the exhaust gases from all cylinders.

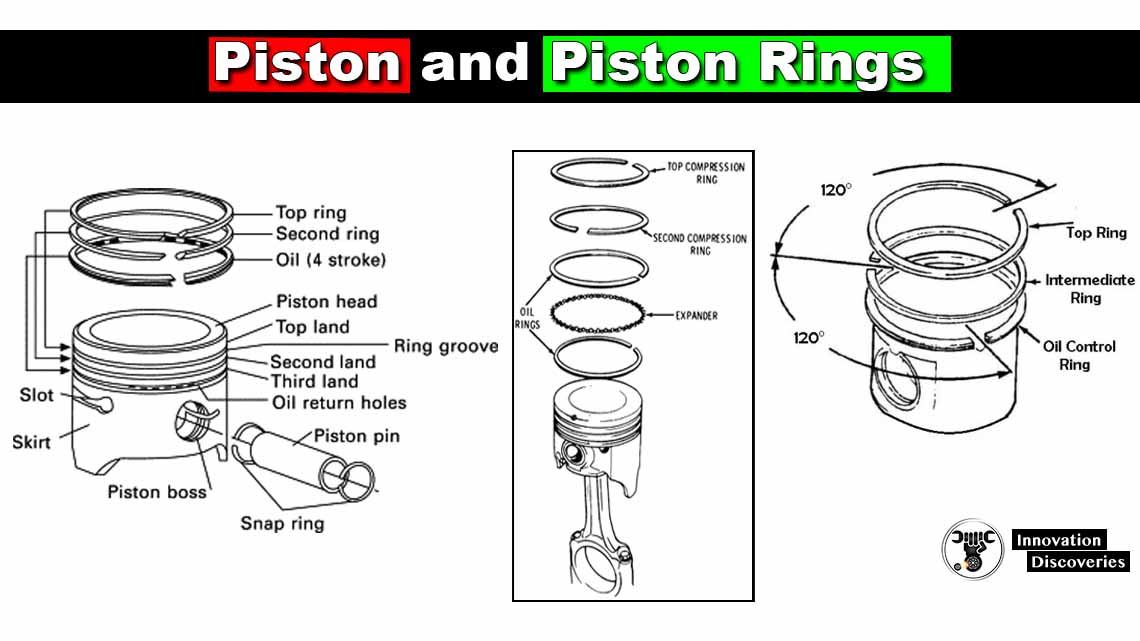

Piston Rings

It provides a good sealing fit and less friction resistance between the piston and cylinder.

It is split at one point so it can be easily installed into the grooves cut in the piston.

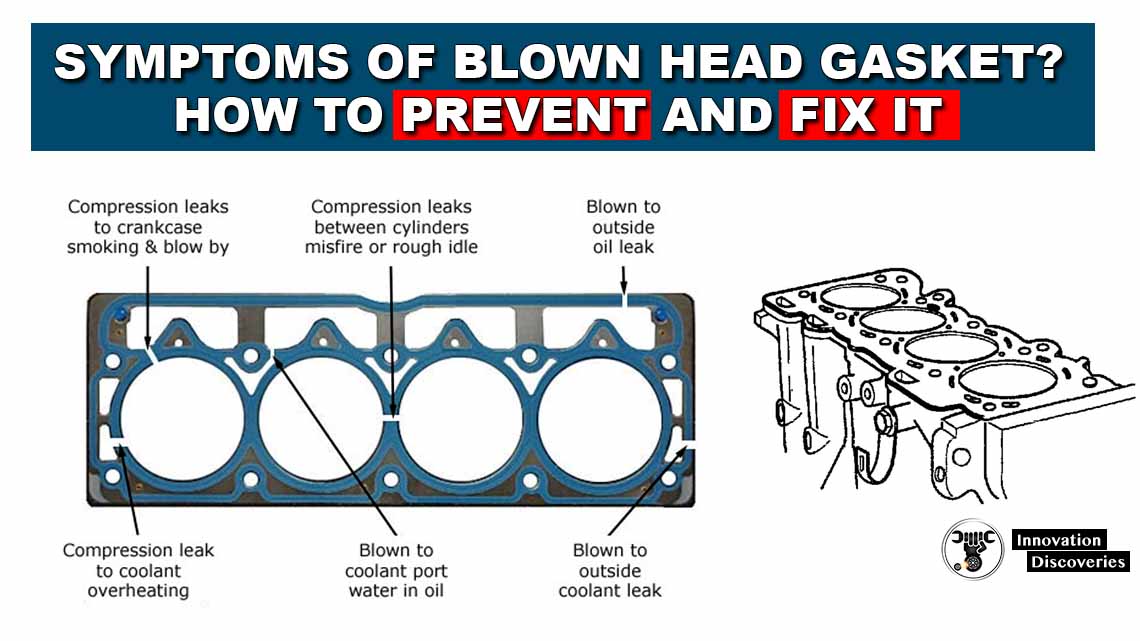

Gaskets

It is used to seal the cylinder head and cylinder so no pressure is allowed to escape.

It is placed between the cylinder block and the cylinder head.

Gudgeon Pin (Piston Pin)

The parallel spindles fitted through the piston boss and connect the rod’s small end. It connects the piston to the connecting rod.

Engine Bearing

Bearings are used to support the moving parts. The purpose of bearings is to reduce friction.

The crankshaft is supported by a bearing. In an engine, two types of bearing are used sliding bearing and rolling bearing.

Working Principle of Diesel Engine

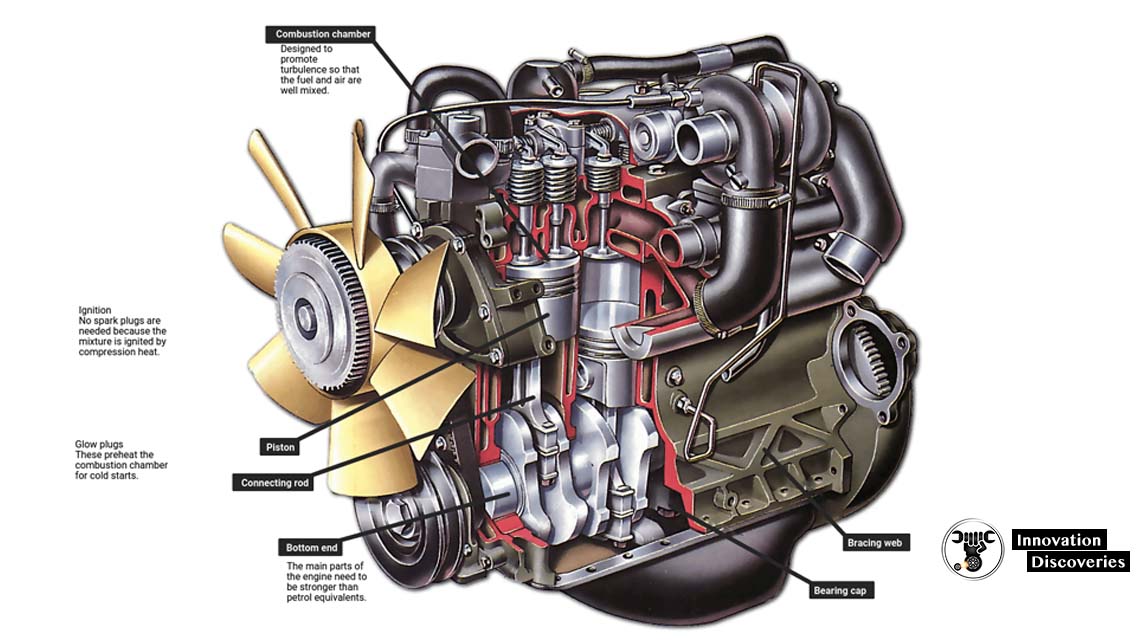

The diesel engine differs from the gasoline-powered Otto cycle by using highly compressed hot air to ignite the fuel rather than using a spark plug (compression ignition rather than spark ignition).

In a diesel engine, only air is initially introduced into the combustion chamber. The air is then compressed with a compression ratio typically between 15:1 and 23:1.

This high compression causes the temperature of the air to rise. At about the top of the compression stroke, fuel is injected directly into the compressed air in the combustion chamber.

This may be into a void in the top of the piston or a pre-chamber depending upon the design of the engine.

The fuel injector ensures that the fuel is broken down into small droplets and that the fuel is distributed evenly.

The heat of the compressed air vaporizes fuel from the surface of the droplets.

The vapour is then ignited by the heat from the compressed air in the combustion chamber.

The droplets continue to vaporize from their surfaces and burn, getting smaller, until all the fuel in the droplets has been burnt.

Combustion occurs at a substantially constant pressure during the initial part of the power stroke.

The start of vaporization causes a delay before ignition, and the characteristic diesel knocking sound as the vapour reaches ignition temperature causes an abrupt increase in pressure above the piston.

When combustion is complete the combustion gases expand as the piston descends further; the high pressure in the cylinder drives the piston downward, supplying power to the crankshaft.

As well as the high level of compression allowing combustion to take place without a separate ignition system, a high compression ratio greatly increases the engine’s efficiency.

Increasing the compression ratio in a spark-ignition engine where fuel and air are mixed before entry to the cylinder is limited by the need to prevent damaging pre-ignition.

Since only air is compressed in a diesel engine, and fuel is not introduced into the cylinder until shortly before the top dead centre (TDC), premature detonation is not a problem, and compression ratios are much higher.

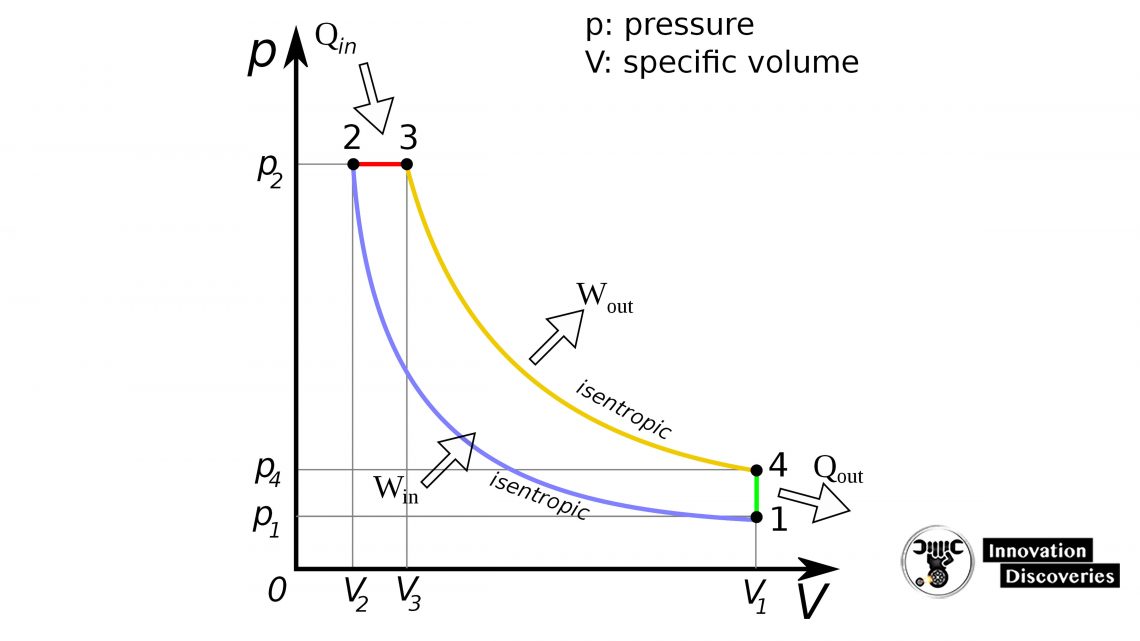

PV Cycle

The p–V diagram is a simplified and idealized representation of the events involved in a diesel engine cycle, arranged to illustrate the similarity with a Carnot cycle.

Starting at 1, the piston is at the bottom dead Centre and both valves are closed at the start of the compression stroke; the cylinder contains air at atmospheric pressure.

Between 1 and 2, the air is compressed adiabatically—that is, without heat transfer to or from the environment—by the rising piston.

(This is only approximately true since there will be some heat exchange with the cylinder walls.)

During this compression, the volume is reduced, and the pressure and temperature both rise.

At or slightly before 2 (TDC), fuel is injected and burns in the compressed hot air.

Chemical energy is released, and this constitutes an injection of thermal energy (heat) into the compressed gas.

Combustion and heating occur between 2 and 3.

In this interval, the pressure remains constant since the piston descends, and the volume increases; the temperature rises as a consequence of the energy of combustion.

At 3 fuel injection and combustion are complete, and the cylinder contains gas at a higher temperature than at 2.

Between 3 and 4 this hot gas expands, again approximately adiabatically. Work is done on the system to which the engine is connected.

During this expansion phase, the volume of the gas rises, and its temperature and pressure both fall.

At 4 the exhaust valve opens, and the pressure falls abruptly to atmospheric (approximately).

This is an unresisted expansion, and no useful work is done by it.

Ideally, the adiabatic expansion should continue, extending lines 3–4 to the right until the pressure falls to that of the surrounding air,

But the loss of efficiency caused by this unresisted expansion is justified by the practical difficulties involved in recovering it (the engine would have to be much larger).

After the opening of the exhaust valve, the exhaust stroke follows, but this (and the following induction stroke) are not shown on the diagram.

If shown, they would be represented by a low-pressure loop at the bottom of the diagram.

At 1 it is assumed that the exhaust and induction strokes have been completed, and the cylinder is again filled with air.

The piston-cylinder system absorbs energy between 1 and 2—this is the work needed to compress the air in the cylinder, and is provided by mechanical kinetic energy stored in the flywheel of the engine.

Work output is done by the piston-cylinder combination between 2 and 4.

The difference between these two increments of work is the indicated work output per cycle and is represented by the area enclosed by the p–V loop.

The adiabatic expansion is in a higher-pressure range than that of the compression because the gas in the cylinder is hotter during expansion than during compression.

It is for this reason that the loop has a finite area and the net output of work during a cycle is positive.

Advantages

- Diesel fuel has a higher energy density.

- A smaller volume of fuel is required to perform a specific amount of work.

- Heavier fuels like diesel fuel have higher cetane ratings and lower octane ratings, resulting in an increased tendency to ignite spontaneously.

- They have no high-voltage electrical ignition system, resulting in high reliability and easy adaptation to damp environments.

- For any given partial load, the fuel efficiency (mass burned per energy produced) of a diesel engine remains nearly constant, as opposed to petrol and turbine engines, which use proportionally more fuel with partial power outputs.

- The carbon monoxide content of the exhaust is minimal.

Discover More:

Visit Forum

Visit Our Friendly Website