When it comes to upgrading a vehicle’s performance, many enthusiasts focus on increasing horsepower or improving aerodynamics. However, a critical aspect that often deserves more attention is the braking system. High-performance brake systems not only enhance stopping power but also improve safety and vehicle control, especially during high-speed driving or on the racetrack.

This article dives into the advanced theory behind high-performance braking systems and provides a step-by-step guide to installing them.

Understanding High-Performance Brake Systems

1. The Basics of Braking

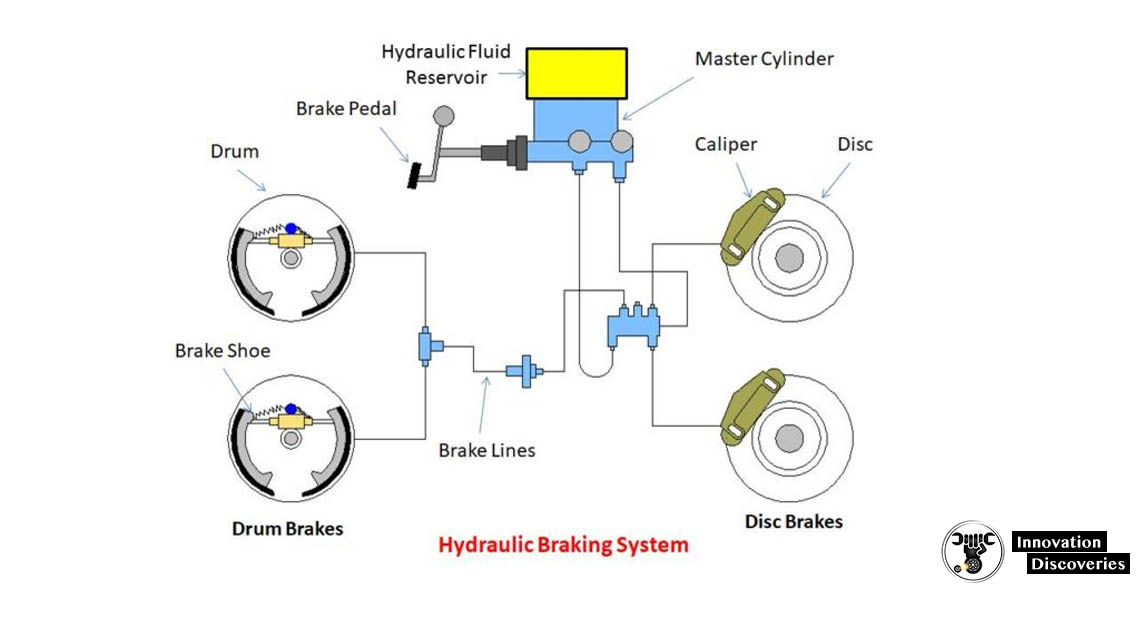

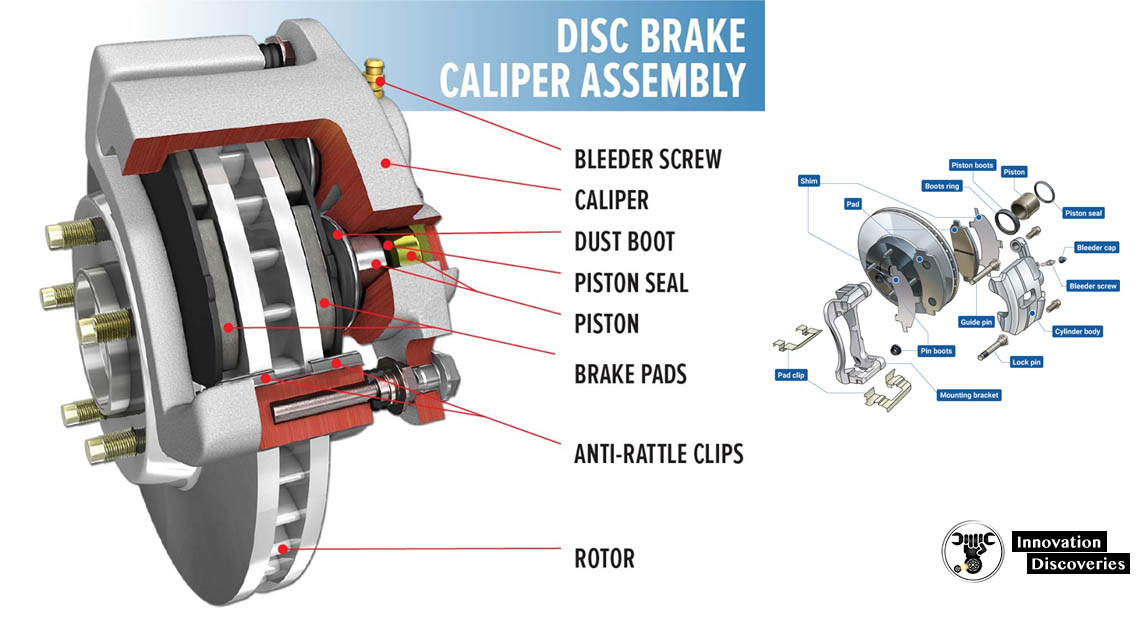

A braking system converts a vehicle’s kinetic energy into heat energy through friction, slowing down or stopping the vehicle. The main components involved in this process include:

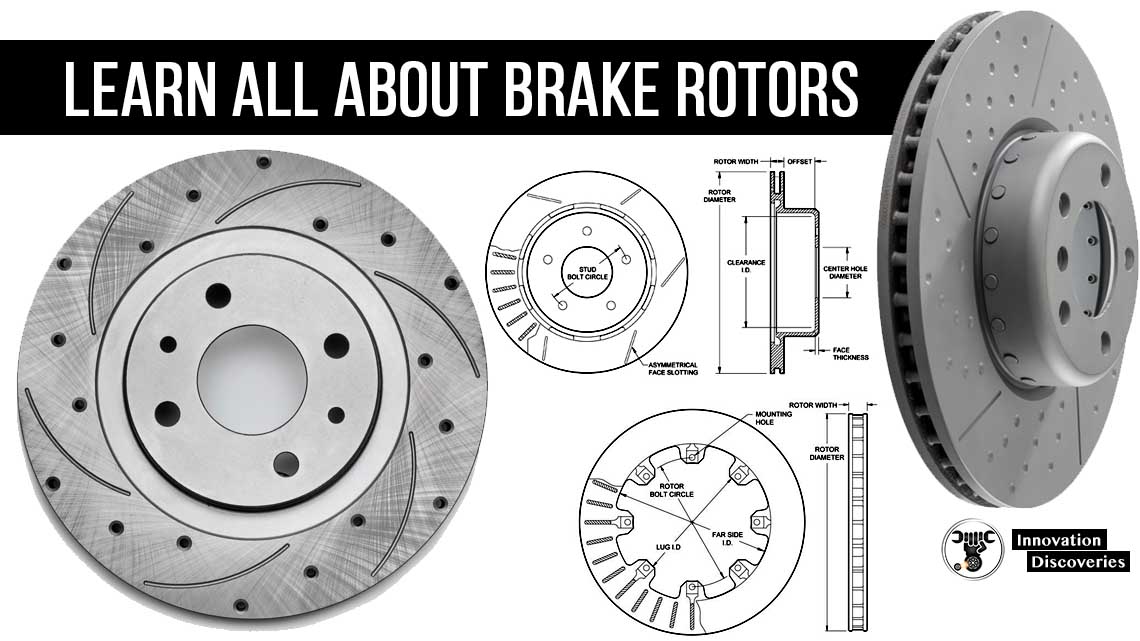

- Brake Rotors (Discs): Rotating components attached to the wheel hub.

- Brake Pads: Friction material that presses against the rotors.

- Calipers: Mechanisms that apply pressure to the brake pads.

- Brake Fluid: Transfers force from the brake pedal to the calipers.

2. What Makes a Brake System High-Performance?

High-performance brake systems are engineered to handle the extreme heat and stress associated with high-speed driving and repeated heavy braking. Key features include:

- Larger Rotors: Provide a greater surface area for heat dissipation.

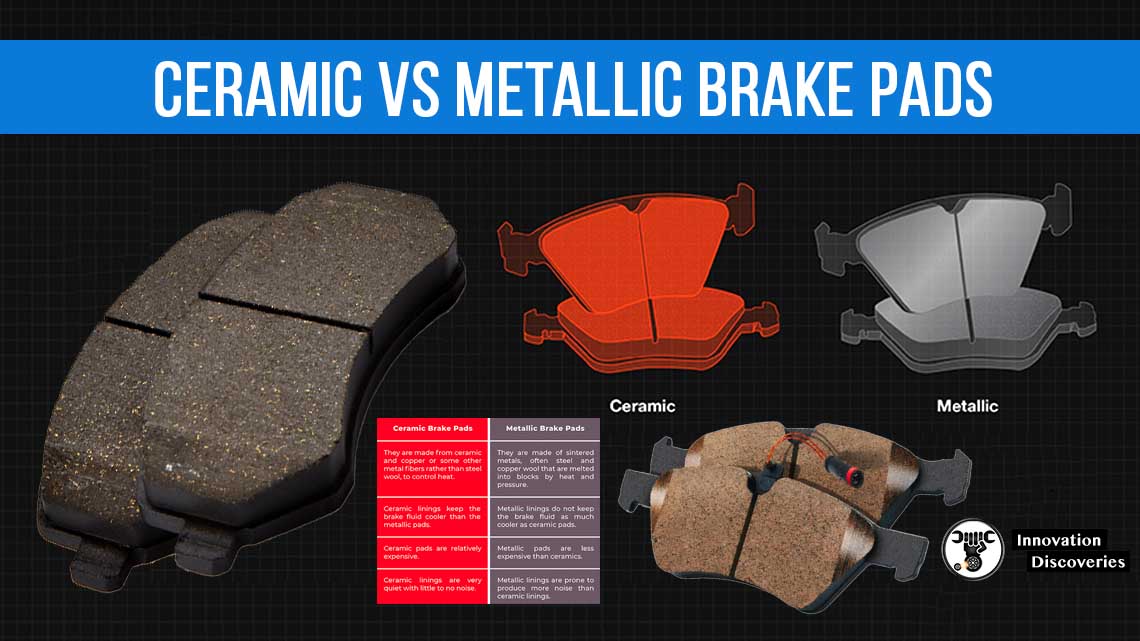

- Performance Brake Pads: Made from advanced materials (e.g., carbon-ceramic, semi-metallic) for superior friction.

- Multi-Piston Calipers: Offer more even pressure distribution on the pads.

- Stainless Steel Brake Lines: Reduce flex and ensure consistent braking.

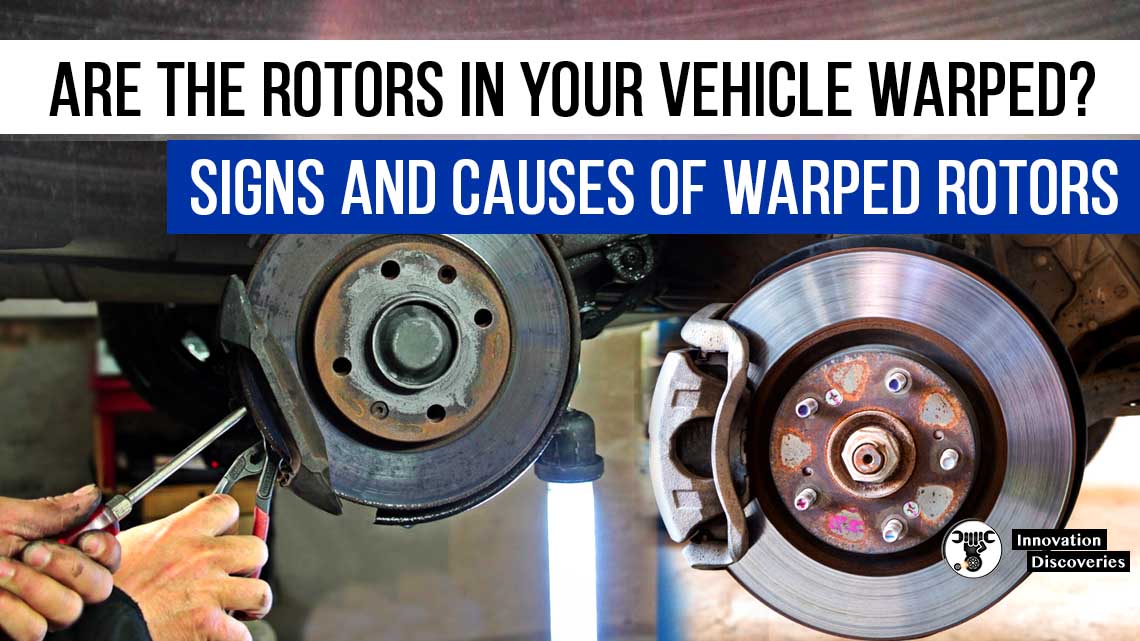

- Improved Ventilation: Slotted or drilled rotors enhance cooling and prevent brake fade.

3. The Science of Braking Performance

- Friction Coefficients: Performance brake pads have higher friction coefficients, improving stopping power.

- Heat Management: Advanced materials dissipate heat more effectively, reducing the risk of brake fade.

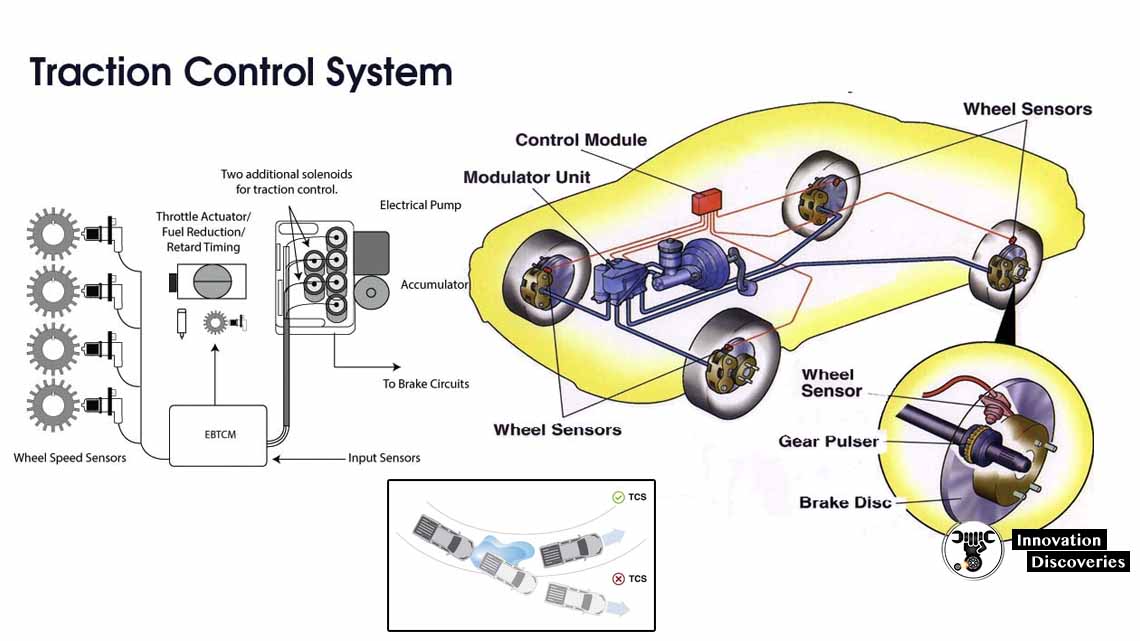

- Brake Bias: Adjusting the balance of braking force between front and rear wheels optimizes control and stability.

Advantages of Upgrading to High-Performance Brake Systems

- Enhanced Stopping Power: Reduced stopping distances, even under high-speed or emergency conditions.

- Improved Heat Resistance: Prevents brake fade during prolonged use, such as on racetracks.

- Better Pedal Feel: Enhanced responsiveness and consistency underfoot.

- Increased Durability: Components designed to withstand higher stress levels and temperatures.

- Aesthetic Appeal: Upgraded systems often include visually appealing calipers and rotors.

Step-by-Step Guide to Installing a High-Performance Brake System

Tools and Materials Needed

- Jack and jack stands

- Lug wrench

- Socket set and wrenches

- Brake fluid and bleeder kit

- High-performance brake kit (rotors, pads, calipers, and lines)

- Torque wrench

- Brake cleaner

Preparation

- Choose the Right Kit: Ensure compatibility with your vehicle’s make and model.

- Gather Tools: Have all necessary tools and materials ready.

- Safety First: Work on a flat surface and use jack stands to secure the vehicle.

Installation Steps

1. Remove Existing Components

- Loosen the lug nuts and lift the vehicle with a jack.

- Remove the wheels to access the brake assembly.

- Unbolt the calipers and support them with a wire to avoid stress on the brake lines.

- Slide off the rotors and remove the brake pads.

2. Install New Rotors

- Clean the new rotors with brake cleaner to remove any protective coating.

- Slide the rotors onto the hub and secure them with retaining screws (if applicable).

3. Install New Calipers and Pads

- Mount the new calipers and torque the bolts to the manufacturer’s specifications.

- Insert the high-performance brake pads into the caliper bracket.

4. Replace Brake Lines

- Disconnect the old rubber brake lines and install stainless steel braided lines for improved durability and performance.

- Ensure all connections are secure and leak-free.

5. Bleed the Brakes

- Use a bleeder kit to remove air from the brake lines, starting with the wheel farthest from the master cylinder.

- Refill the system with high-quality brake fluid and ensure a firm pedal feel.

6. Reassemble and Test

- Reinstall the wheels and lower the vehicle.

- Test the brakes at low speeds to ensure proper installation and performance.

Maintenance Tips for High-Performance Brakes

- Regular Inspection: Check pads, rotors, and lines for wear or damage.

- Monitor Brake Fluid: Use performance brake fluid and replace it as recommended.

- Keep Components Clean: Remove debris and dirt to prevent premature wear.

- Avoid Excessive Heat: Allow the brakes to cool during heavy use.

- Torque Check: Periodically ensure all bolts and fittings are secure.

Conclusion

Upgrading to a high-performance brake system can transform your driving experience, offering better control, shorter stopping distances, and improved durability. By understanding the theory behind these systems and following proper installation techniques, you can ensure both safety and performance.

Whether you’re a weekend track enthusiast or a driver seeking improved safety on the road, investing in a high-performance brake system is a decision that pays off. For more automotive insights and tutorials, stay tuned to Innovation Discoveries!

Discover More:

Also, Read:

More About Braking Systems

- Top 5 Causes of Steering Wheel Shakes at Low and High Speeds

- HOW HYDRAULIC BRAKE WORKS?

- AIR BRAKE SYSTEM: COMPONENTS, WORKING PRINCIPLE, AND APPLICATIONS

- HOW DOES REGENERATIVE BRAKING WORK?

- 8 REASONS YOUR CAR IS MAKING GRINDING NOISE WHEN BRAKING

- Regenerative Braking System

- JAKE BRAKE VS. EXHAUST BRAKE: WHICH IS BETTER?

- SQUEALING BRAKES AT LOW SPEED: CAUSES AND SOLUTIONS

- TROUBLESHOOTING A HARD BRAKE PEDAL

- CONVERT DRUM BRAKES TO DISC BRAKES IN 3 STEPS!

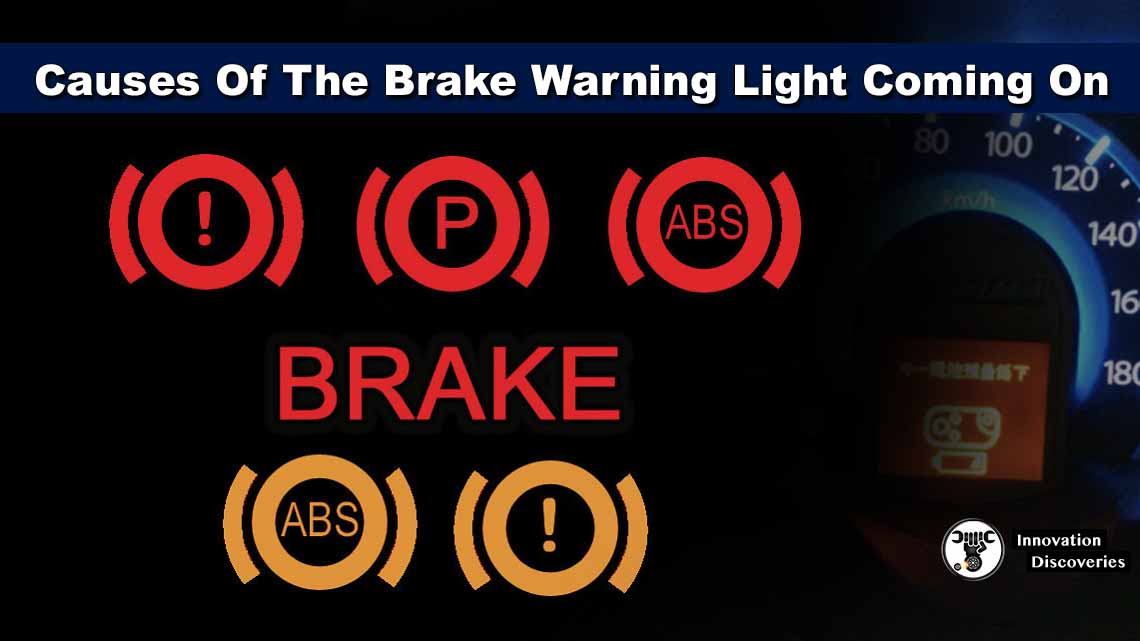

- CAUSES OF THE BRAKE WARNING LIGHT COMING ON

Download: BRAKES, BRAKE CONTROL AND DRIVER ASSISTANCE SYSTEMS: FUNCTION, REGULATION AND COMPONENTS

READ: HOW HYDRAULIC BRAKE WORKS?

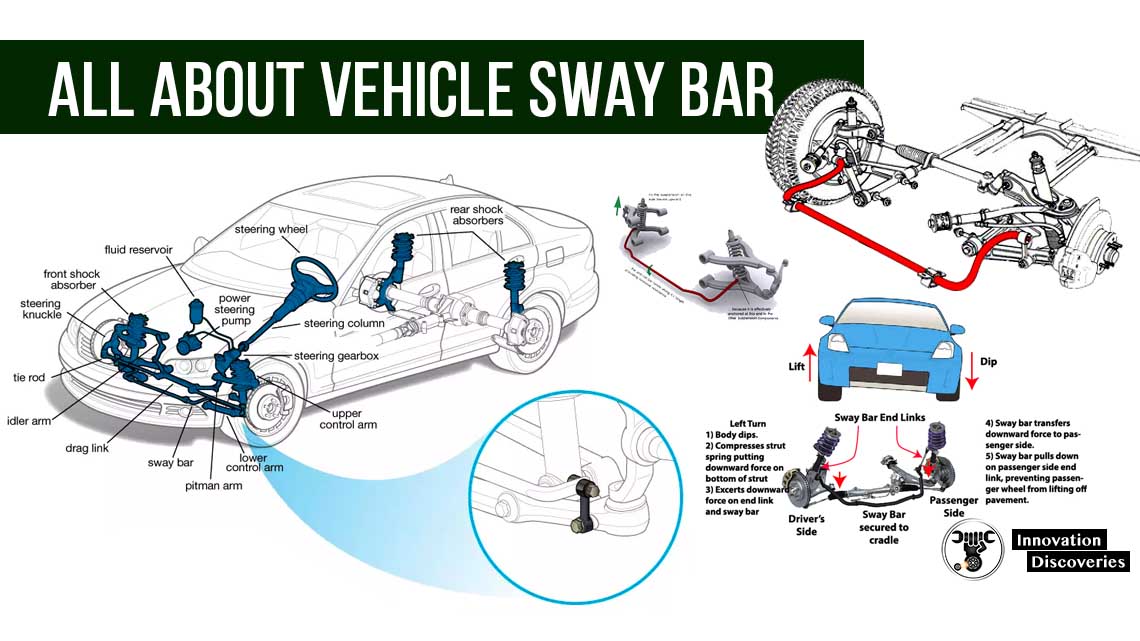

READ: All About Vehicle Sway bar

Also, read: The Importance of Measuring Brake Pad Thickness

Visit Forum

Visit Our Friendly Website