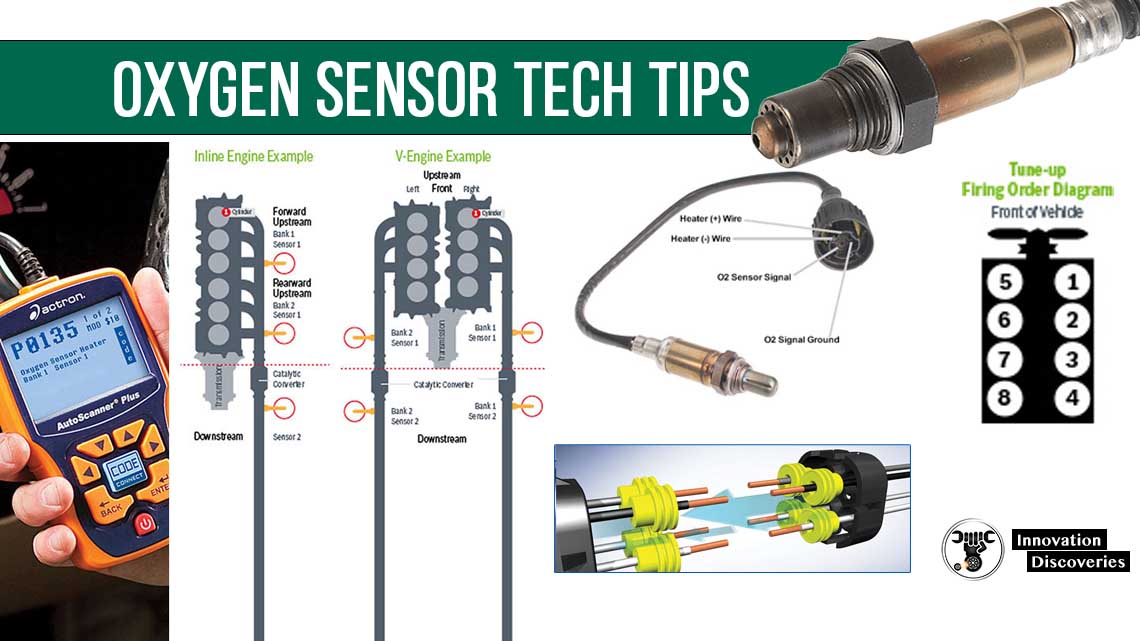

Because engine configurations can vary by vehicle, it’s essential to correctly identify all your oxygen sensors’ specific positions.

So you replace the correct sensor when one of them fails.

The post below clarifies which oxygen sensor to change and a few technical tips to assist in a smooth installation process.

OXYGEN SENSORS /LAMBDA SENSOR/: PARTS, TYPES, WORKING PRINCIPLE AND LOCATION

Knowing which Sensor to Change

Sensor Locations

Refer to your vehicle service manual to determine your sensor locations. If the manual is not available, here are some guidelines that apply to most vehicles:

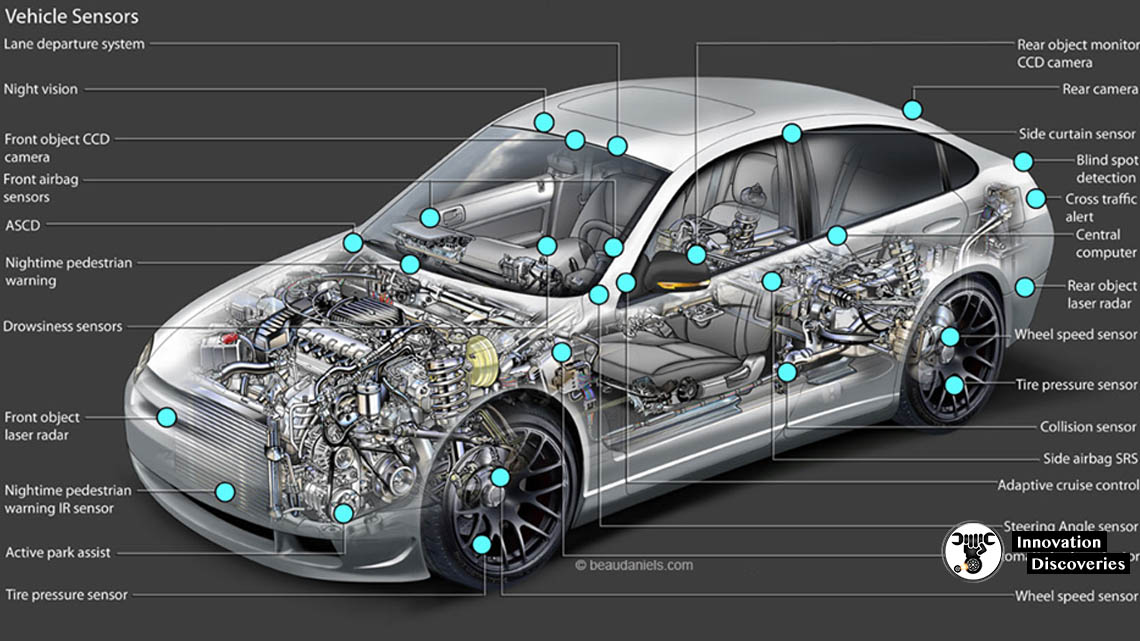

RELATED CONTENT- VEHICLE SENSORS: FUNCTIONS AND TYPES

Read More:

- VEHICLE SENSORS: FUNCTIONS AND TYPES

- WHAT IS PROXIMITY SENSOR, ITS TYPES AND WORKING

- STATE EMISSIONS INSPECTION

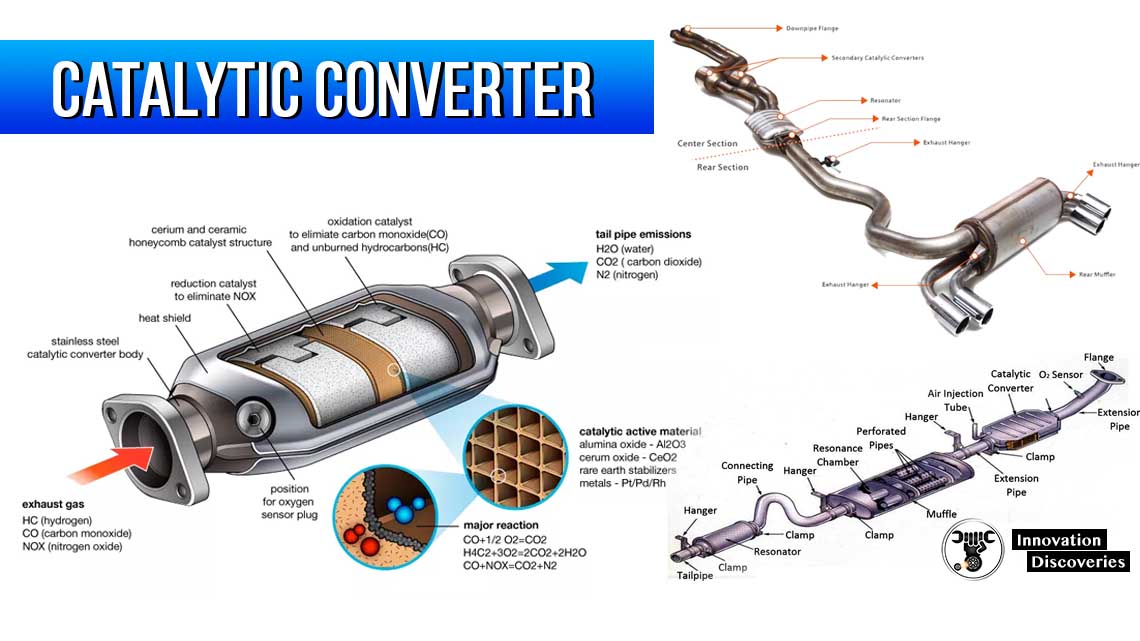

- CATALYTIC CONVERTER

Location by Code

- Carmakers generally define Bank 1 as the Bank containing Cylinder 1.

- If you don’t know your Cylinder 1 location, ask your auto parts store associate for a cylinder-number- or firing-order diagram for your vehicle.

See the example below.

- Sensor 1 is the upstream sensor, and Sensor 2 do generally located after the catalyst (downstream)

- On a 3 sensor per bank system, Sensor 2 is located on the catalyst, and Sensor 3 is located after the catalyst.

Catalog Locations

- The front of the engine contains the belt and alternator.

- The transmission does mount to the rear of the engine.

- Left and right are defined looking from the rear to the front of the engine.

- On rear-wheel-drive applications, this is the view from the driver’s seat.

- Use the bank detail (at left) to determine if you need a forward, rearward, left, or right sensor.

READ:

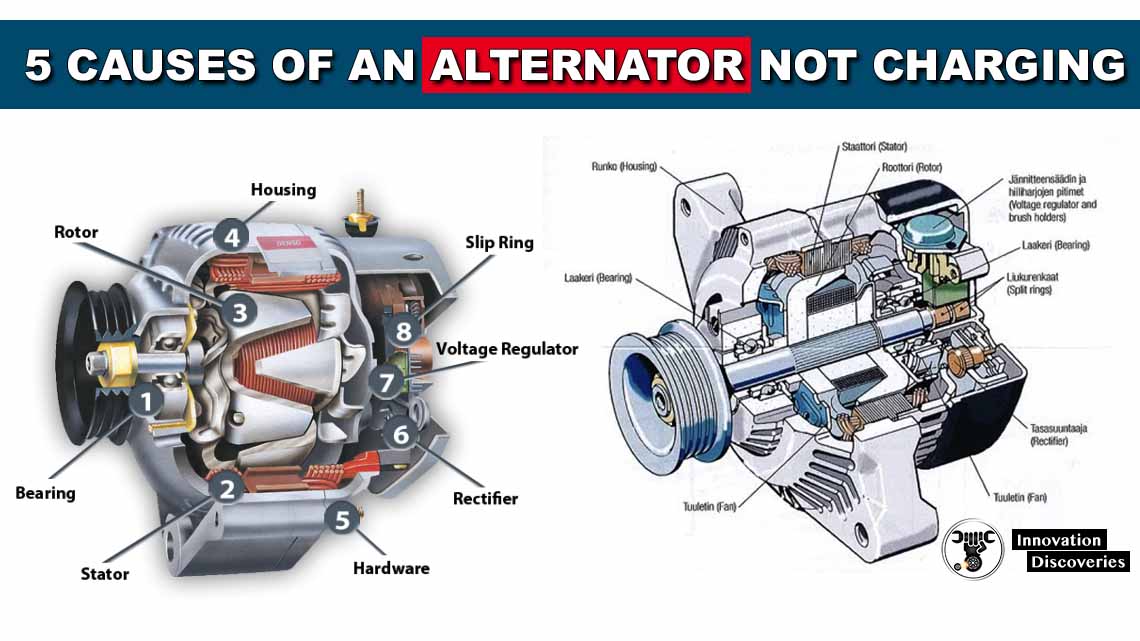

- MOST COMMON LOOSE ALTERNATOR BELT SYMPTOMS

- CAR ALTERNATOR FUNCTIONS AND SYMPTOMS OF FAILURE

- 5 SIGNS OF A BAD ALTERNATOR

- 5 CAUSES OF AN ALTERNATOR NOT CHARGING

- STARTING AND CHARGING SYSTEMS

Installation Tip

Disconnect the Battery

Many vehicles require a sensor learning trigger from a scan tool after a new sensor does install.

Clearing codes does not initiate this learning process, but often a 5-minute battery disconnect can.

So, not only is having the battery cable disconnected during service recommended for safety, but it can also help you avoid unnecessary service.

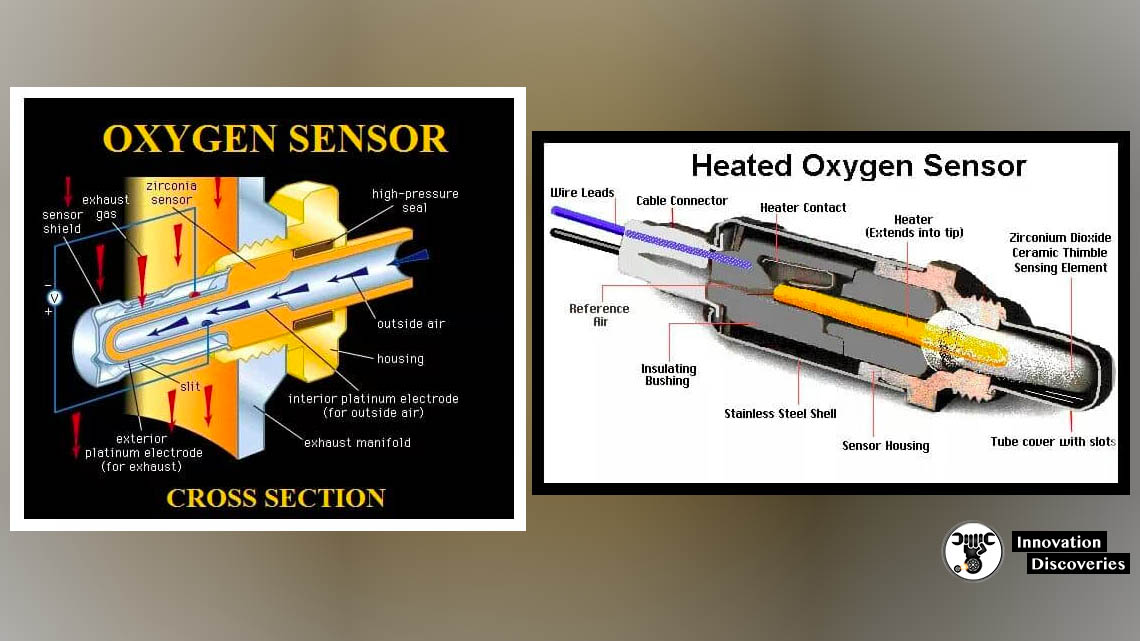

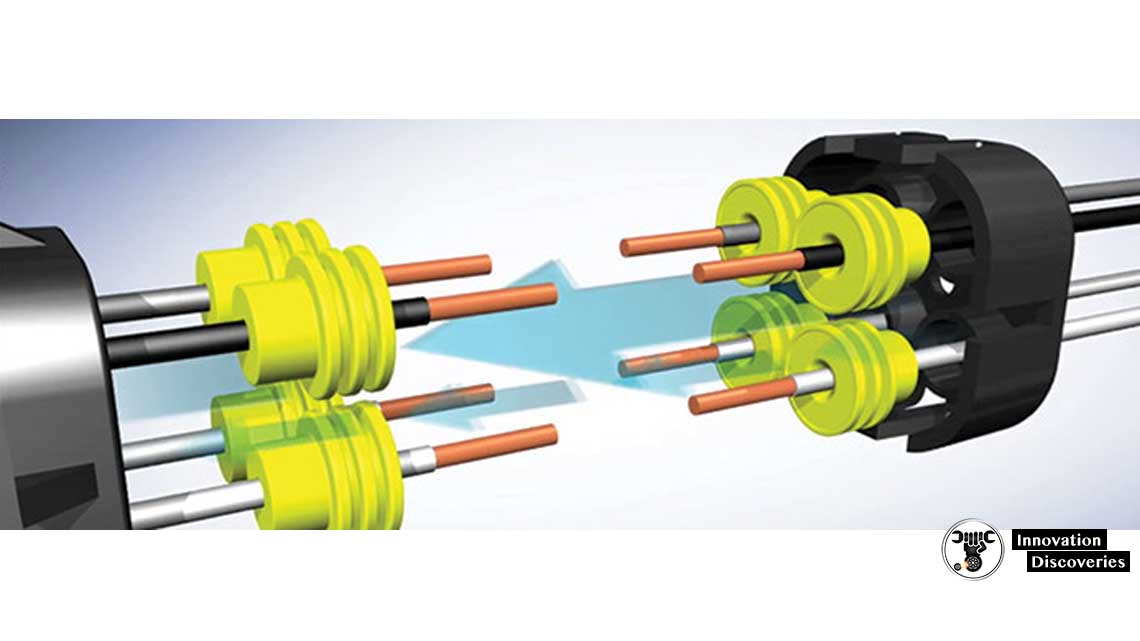

Reference Air

Because Oxygen Sensors require a clean reference air sample to function properly:

- Mustn’t damage the wiring harness during installation.

- The use of dielectric grease, cleaners, and other chemicals in the connector or sensor can cause permanent damage.

Discolored / Seared Protection Tube Ensures High Quality

Some customers have noticed a dark discoloration on Bosch sensors and question if the part is used.

- Rest assured that this discoloration is normal and the result of one of many processes we utilize during manufacturing to ensure quality and performance.

Visit Forum

Visit Our Friendly Website