Introduction

The quality and performance of railway tracks are significantly influenced by the formation of the track bed. Proper foundation and formation techniques are crucial for ensuring stability and longevity.

Earthwork

Usual Forms of Cross-Sections

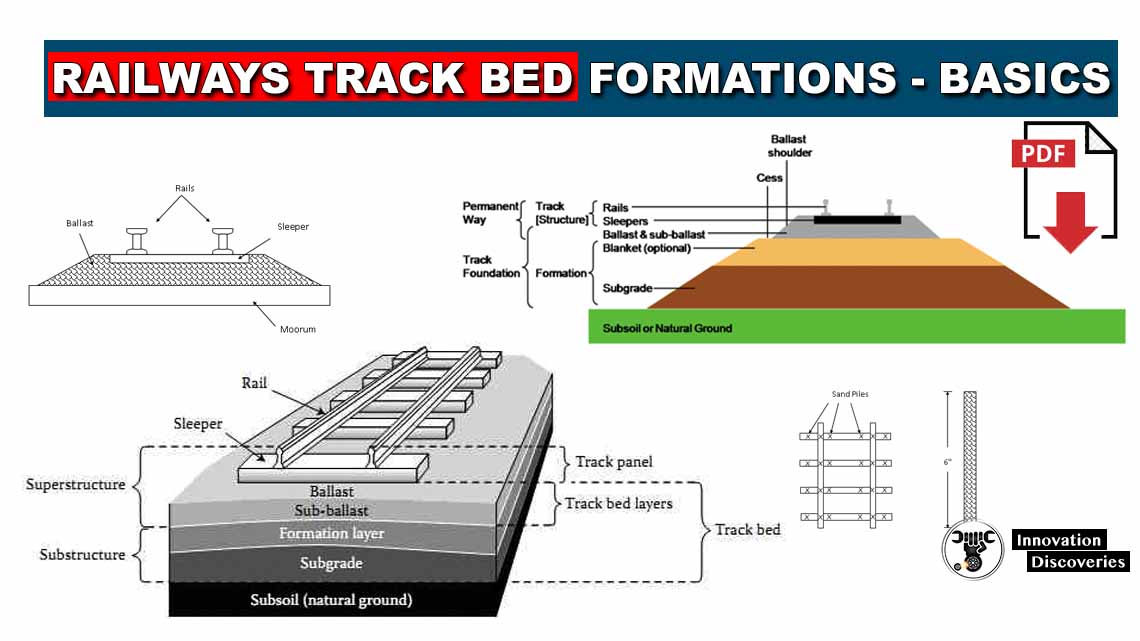

- Subgrade: The naturally occurring soil on which the track bed is constructed.

- Formation: When the subgrade is prepared to receive the ballast and track, it is called the formation.

- Embankment: When a formation is raised on a bank of earth, it is termed an embankment.

- Cutting: When a formation is made by cutting into the ground, it is called a cutting. Here, the track is laid below ground level, necessitating excavation of the required portion.

Railway lines are typically constructed on flat ground, embankments, cuttings, or a combination of these sections.

Features of Rail Track Bed Level

When constructing a formation on embankments or cuttings, several features must be carefully considered:

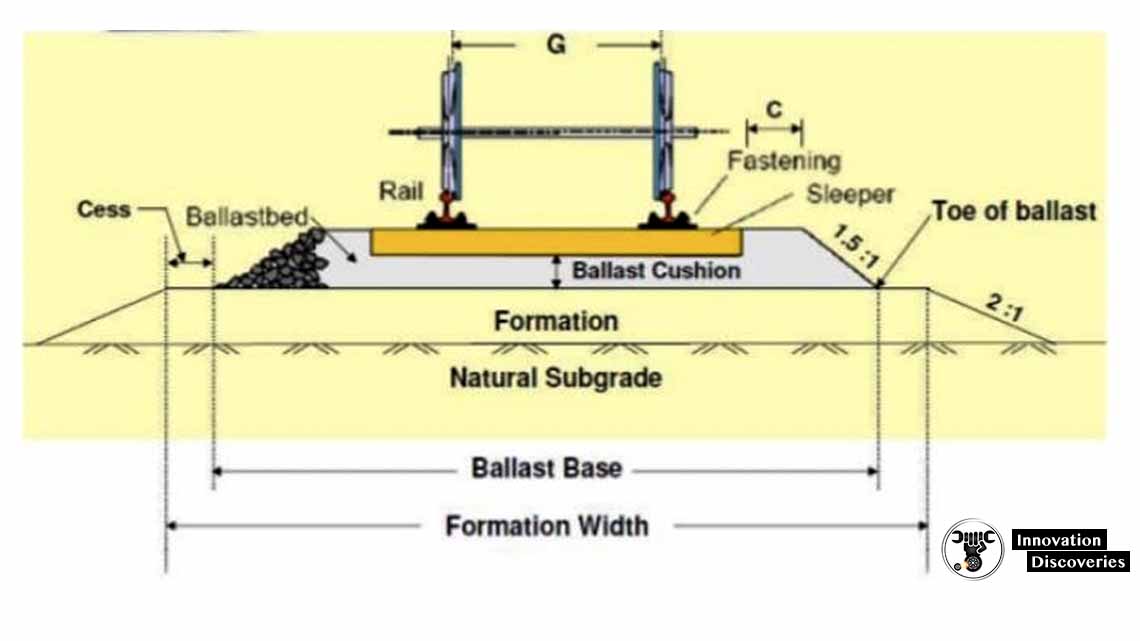

1. Width of Formation

The width of the formation depends on several factors:

- Number of tracks

- Gauge of tracks

- Center-to-center distance between tracks

- Width of the ballast layer

- Width of trenches if needed

2. Slopes of Sides

The stability of the earthwork is influenced by two factors: cohesion and friction.

- Cohesion provides temporary stability.

- Friction ensures permanent stability by maintaining the natural angle of repose of the material.

Slopes should be slightly flatter than the material’s angle of repose. In cuttings, the slopes typically vary from 1.5:1 or steeper.

3. Drains

Water accumulation reduces soil friction, impacting stability. Effective drainage is essential, especially in cuttings where water cannot drain naturally.

- Side Drains: Constructed along the track, typically at a depth of about 1200 mm from the rail level.

- The size of the drains depends on rainfall data.

Stabilization of Track on Poor Soil

Sometimes, tracks must be laid on poor or undesirable soil. Various methods are used to improve and strengthen the soil:

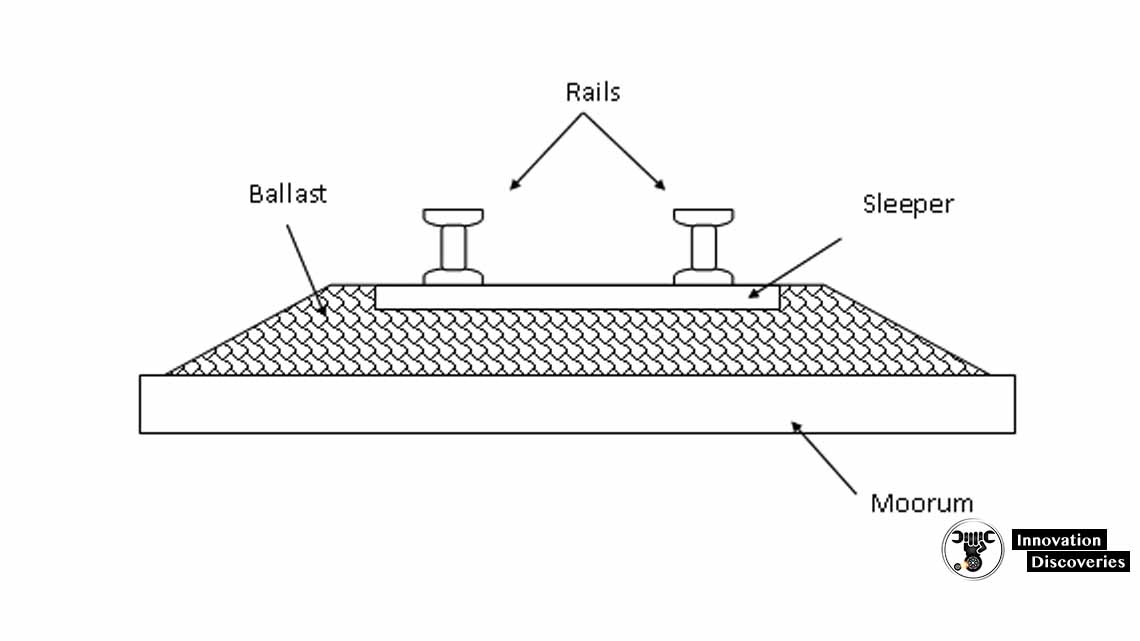

Layer of Moorum

- Moorum: A fine black loamy soil used to stabilize poor-quality soil, such as black cotton soil.

- Properties: Expands when moist and cracks heavily when dry.

- A layer of moorum (300 mm to 600 mm thick) is laid under the ballast to distribute load pressure and prevent ballast loss in soil cracks.

Alternative materials such as ashes, concrete slabs, rubber, or unserviceable sleepers can also be used effectively.

Cement Grouting

- Steel tubes (30 mm in diameter and 1.5 m long) are driven into the foundation at an angle so the tube ends are nearly under the rail.

- Cement grout is injected under pressure (0.7 N/mm²) through these tubes.

- The grout spreads through the poor soil, consolidating it. The tubes are then gradually removed.

Cement grouting is a technique used to stabilize and strengthen soil that has poor bearing capacity, making it suitable for supporting railway tracks. Here’s a detailed description of the process:

- Preparation:

- Steel Tubes: Steel tubes with a diameter of about 30 mm and a length of 1.5 meters are prepared. These tubes are essential for delivering the grout mixture into the soil.

- Insertion:

- The steel tubes are driven into the ground at an angle. The end of each tube should be positioned nearly under the rail to ensure the grout effectively reaches the areas that need stabilization.

- Grout Injection:

- Cement Grout Mixture: The grout is typically a mixture of cement and water, but sometimes other additives are used to improve the properties of the grout.

- Pressure Application: The cement grout is injected through the steel tubes into the soil under high pressure (about 0.7 N/mm²). This pressure ensures that the grout penetrates the soil effectively, filling voids and spaces.

- Soil Consolidation:

- As the grout spreads through the soil, it fills the gaps and binds the soil particles together. This consolidation process increases the soil’s bearing capacity and overall stability.

- Tube Removal:

- After the grout has been injected, the steel tubes are gradually withdrawn. This process ensures that the grout is evenly distributed and that the soil is adequately consolidated around the rail tracks.

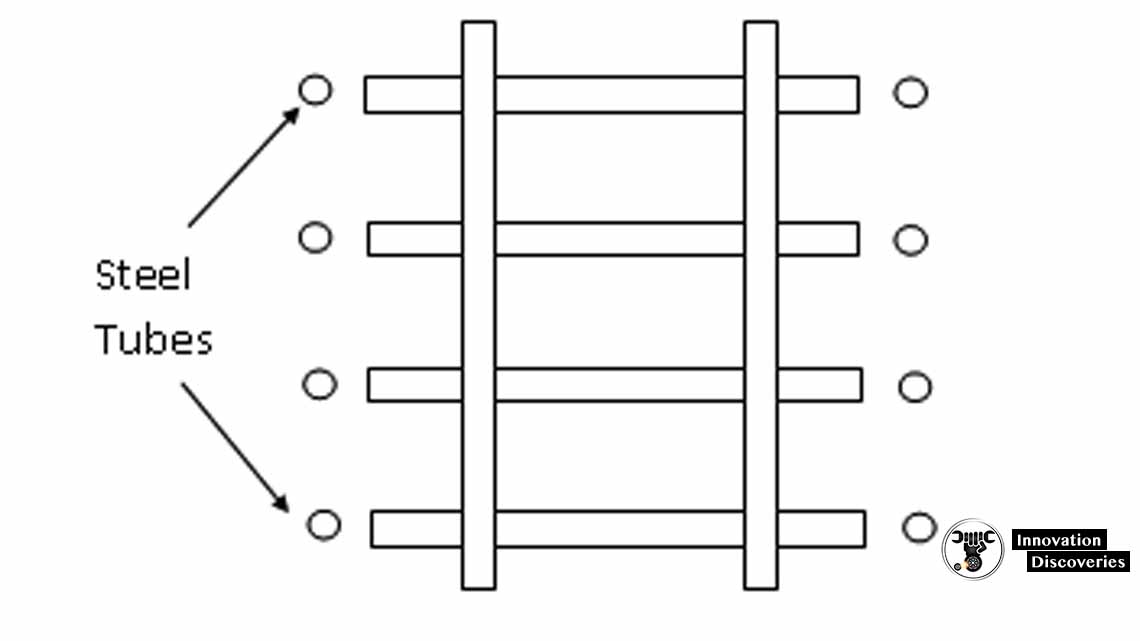

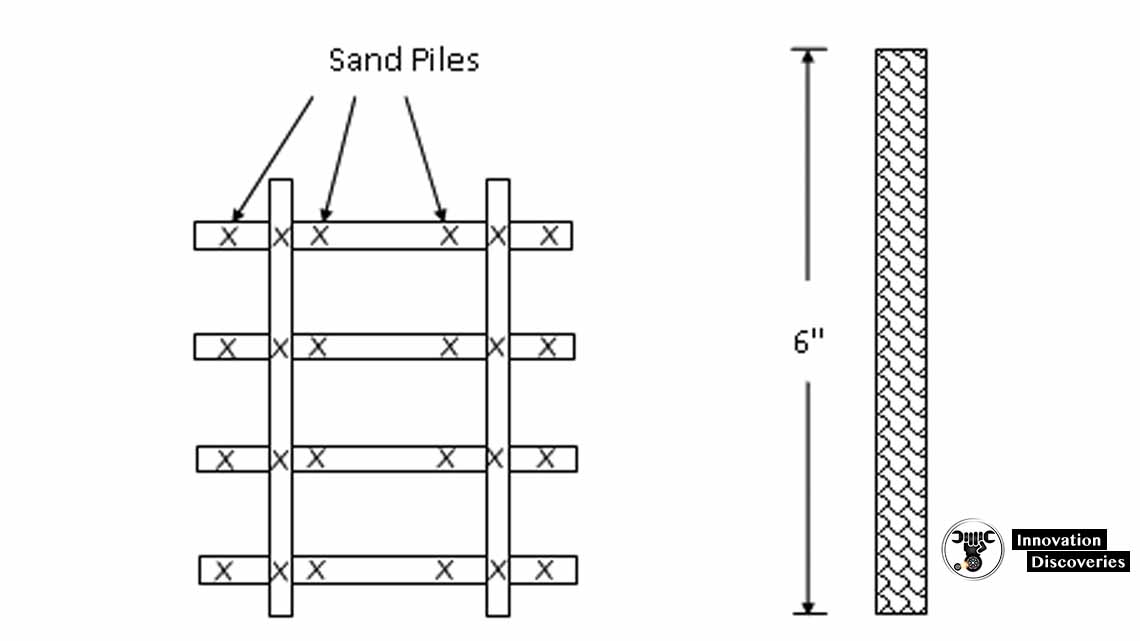

Sand Piles

- A vertical bore (about 300 mm in diameter) is made in the ground using a wooden pile, which is then withdrawn.

- The space is filled with sand and well-rammed.

- Sand piles are arranged so their cross-sectional area is about 20% of the formation area, providing stability.

Sand piling is another method used to improve the load-bearing capacity of poor soil. This method involves the creation of vertical columns of compacted sand within the soil. Here’s a detailed description of the process:

- Boring:

- Vertical Bores: Vertical bores with a diameter of about 300 mm are made in the ground. These bores can be created using mechanical drilling equipment or by driving wooden piles into the ground and then removing them.

- Sand Filling:

- Sand Placement: After the bore is created, it is filled with clean, dry sand.

- Compaction: The sand is then compacted to ensure that it forms a solid, stable column. This compaction can be done using mechanical rammers or other suitable equipment.

- Pattern Arrangement:

- Pattern Design: The sand piles are arranged in a specific pattern, typically in a grid formation. The cross-sectional area of the sand piles should be about 20% of the total formation area to provide sufficient support.

- This pattern ensures that the load from the railway track is evenly distributed across the entire formation, improving stability.

- Top Section Cover:

- The top section of the formation is covered with sand, which helps distribute the load more evenly and provides a stable base for the railway track.

Comparison and Use Cases

- Cement Grouting is often used when a more permanent and robust solution is needed. It is particularly effective in areas where soil has low cohesion and needs to be solidified to support heavy loads.

- Sand Piles are typically used in areas where the soil has moderate instability. This method is common in developing countries due to its simplicity and effectiveness in improving soil stability.

Use of Chemicals

- Chemicals like silicate of soda followed by calcium chloride are used to consolidate sandy soils with less than 25% silt and clay.

Conclusion

Proper track bed formation is crucial for the stability and performance of railway tracks. By understanding and applying various techniques for earthwork, drainage, and soil stabilization, railway tracks can be constructed to endure diverse environmental conditions and maintain their integrity over time.

Read more – Track-basics-v2 | PDF

Discover More:

Visit Forum

Visit Our Friendly Website

3 Comments