Synchronizers are used to reduce gear wear and reduce the noise level during operation resulting from the impact of the teeth when shifting gears.

The synchronizer includes three elements:

- leveling angular velocities (conical rings);

- blocking inclusion (blocking fingers);

- including gears (gear clutch).

The truck gearbox synchronizer is a mobile clutch with a disk, which is affected by the shift fork, and with gear teeth. The coupling is mounted on the splines of the driven shaft.

The clutch disc has three holes for the locking fingers connecting it to two interlocked conical rings, and for the locking fingers that rigidly connect the conical rings. There are springs in the locking fingers.

In the neutral position, the synchronizer housing is located in the middle between the gears, while there are gaps between the conical rings and the conical surfaces of the gears, the locking fingers are located with the ring gaps in the center of the coupling hole.

When the gear is engaged, the synchronizer clutch, moving the locking fingers, presses the conical ring against the conical surface of the gear.

A clutch connected to the driven shaft and a gear connected to the countershaft has different rotational speeds.

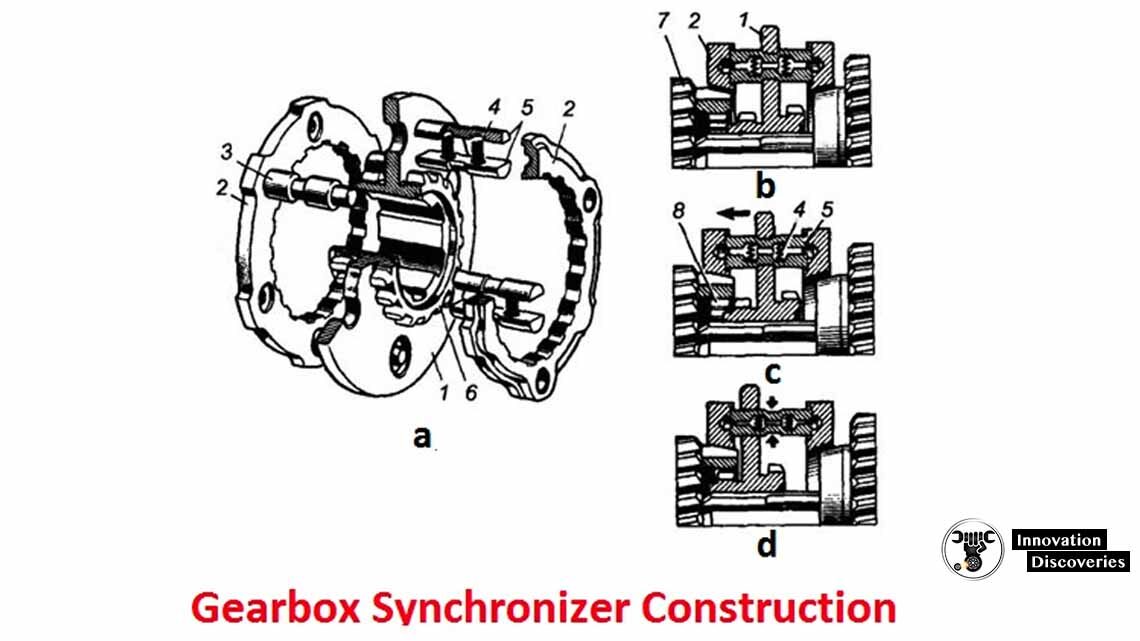

Truck gearbox synchronizer:

a – design;

b – d – work;

1- synchronizer clutch;

2 – a conical ring;

3 – blocking finger;

4 – spring;

5 – a finger of a clamp;

6 – gear ring of the coupling;

7 – a gear wheel;

8 – internal gear ring gear.

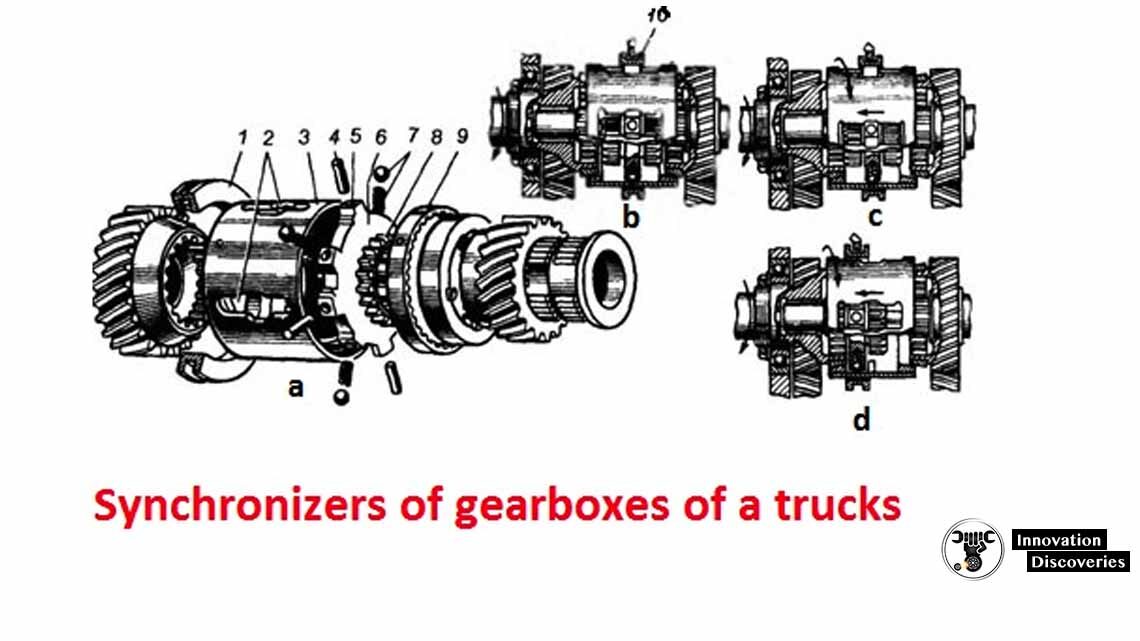

Synchronizers of gearboxes of trucks

а – design;

b – d — work;

1 – a clip of a plug of switching;

2 – slotted body;

3 – case;

4 – pin;

5 – coupling protrusion;

6 – gear ring of the coupling;

7 – a clamp;

8 – internal gear ring of the coupling;

9 – a conical ring;

10 – a clip of a plug of switching.:

Under the action of friction forces arising between the conical surfaces, the conical ring rotates relative to the coupling disk until the locking conical chamfers of the disk openings come in contact with the locking fingers; rings and couplings are blocked.

After aligning the rotational speeds of the gear of the driven shaft, and consequently, of the conical rings with locking fingers and the coupling, the locking action of the fingers ends, the coupling moves further, and its teeth engage silently with the gear ring of the corresponding gear.

Similarly work synchronizers and other designs.

2 Comments