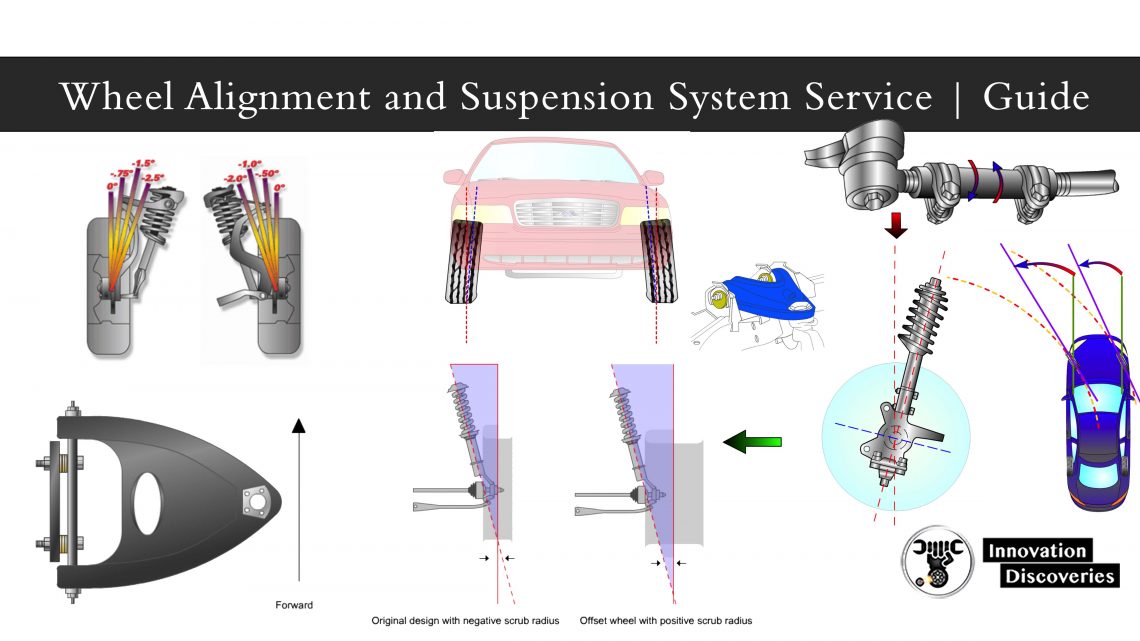

Wheel Alignment

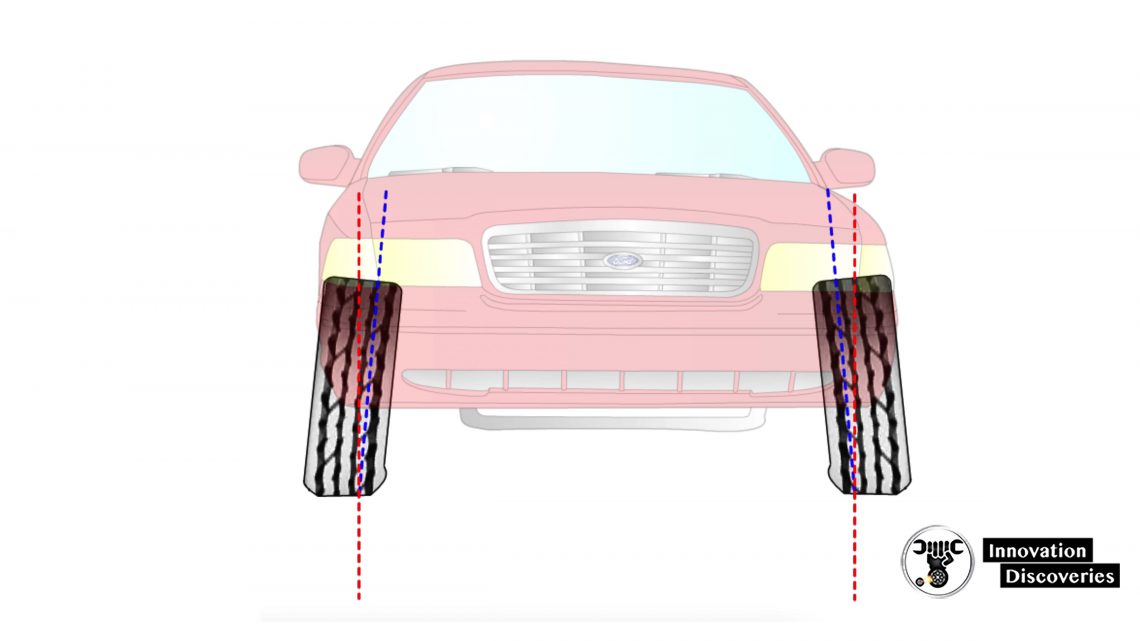

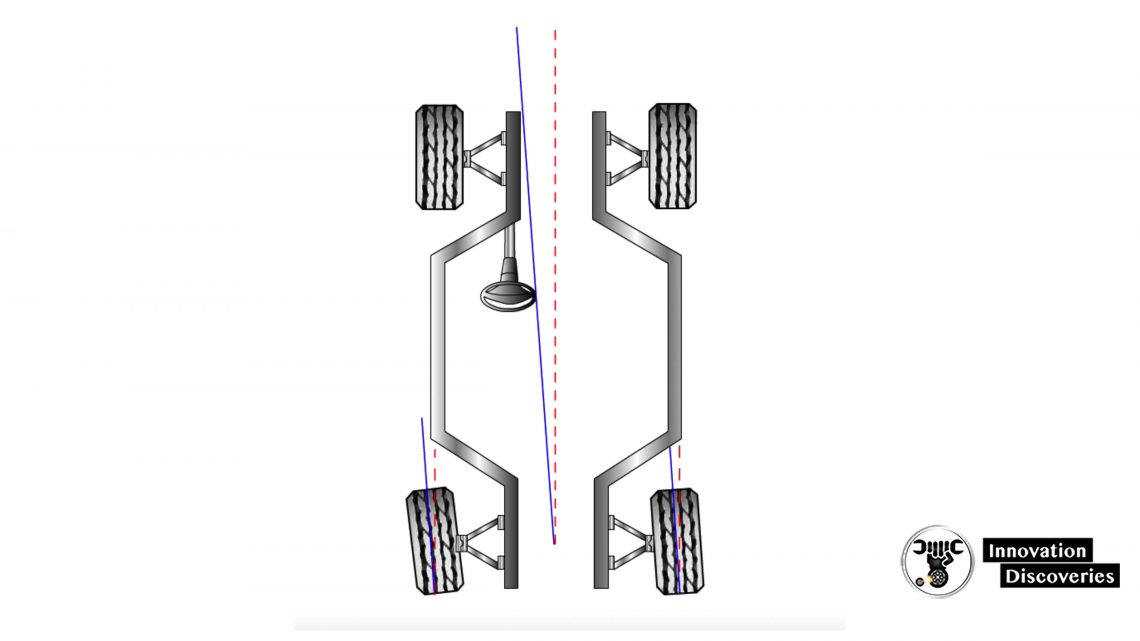

Camber Angle

- Camber is the amount that the centerline of the wheel tilts away from true vertical when viewed from the front of the vehicle

- Camber places the tire tread flat on the road reducing tire wear and improving vehicle handling

- Excessive camber will cause wear on the edge of the tire’s tread

Camber Split

- Camber split is the difference between the left and right camber settings

- Excessive camber split will cause a vehicle to pull to the most positive side

- Camber split should be limited to ½ a degree or less to prevent vehicle pull

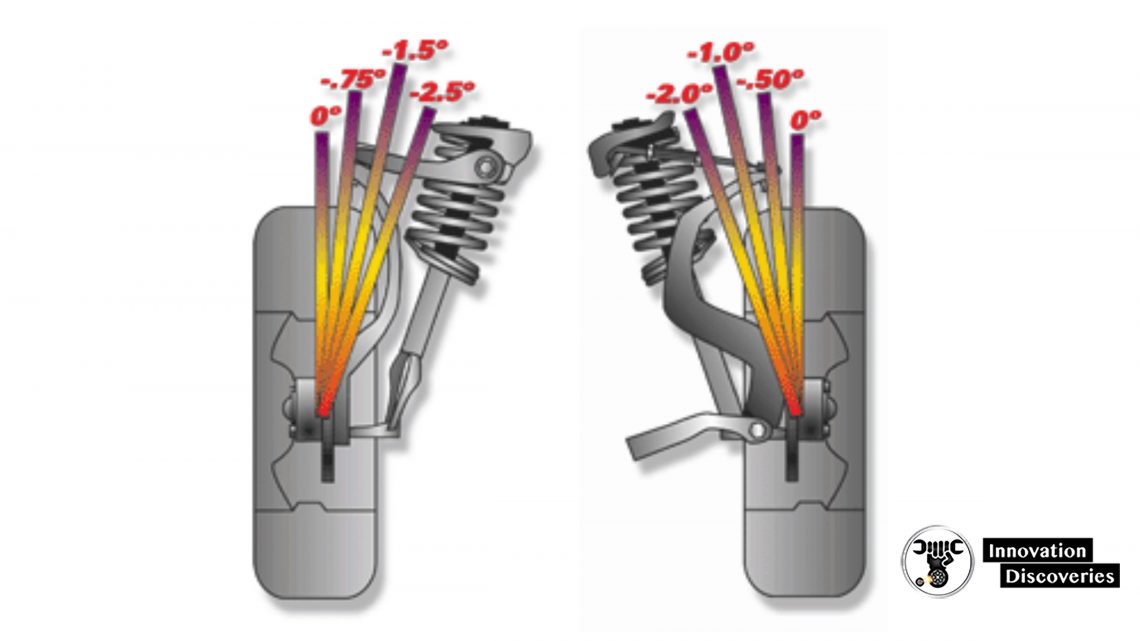

Caster Angle

- Positive caster is the rearward tilt of the steering axis

- Negative caster is the forward tilt of the steering axis

- The vehicle will pull to the least positive side

- Not a tire wear angle

- The caster aids in directional stability and steering wheel return

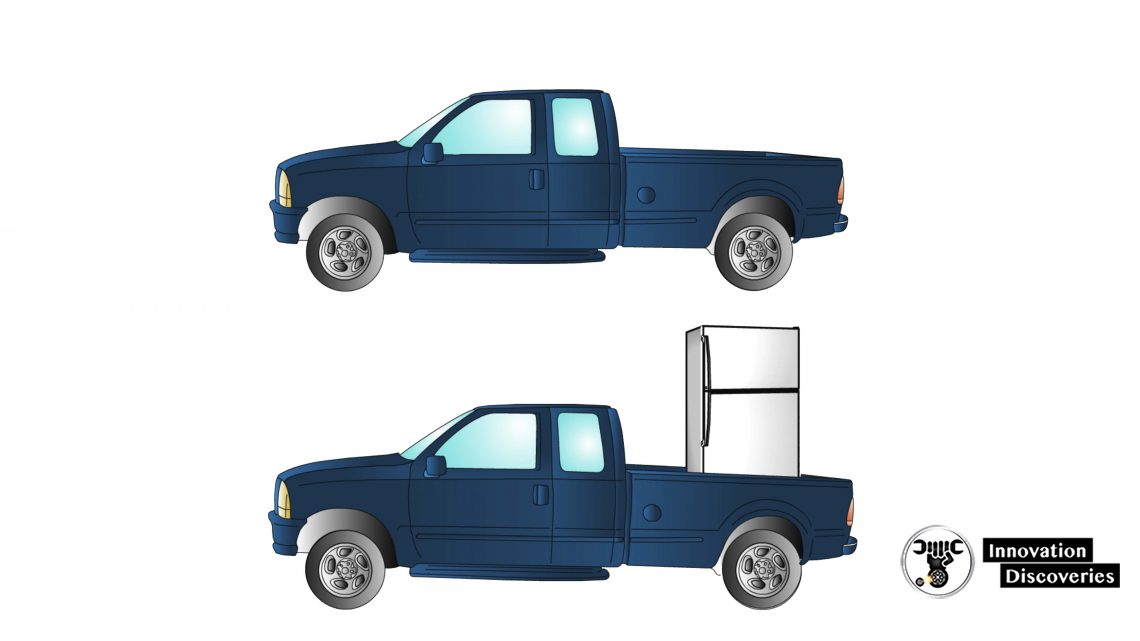

Caster and Ride Height

- It is important to consider normal vehicle loading when performing alignment checks and adjustments

- What effect does loading the truck have on the caster?

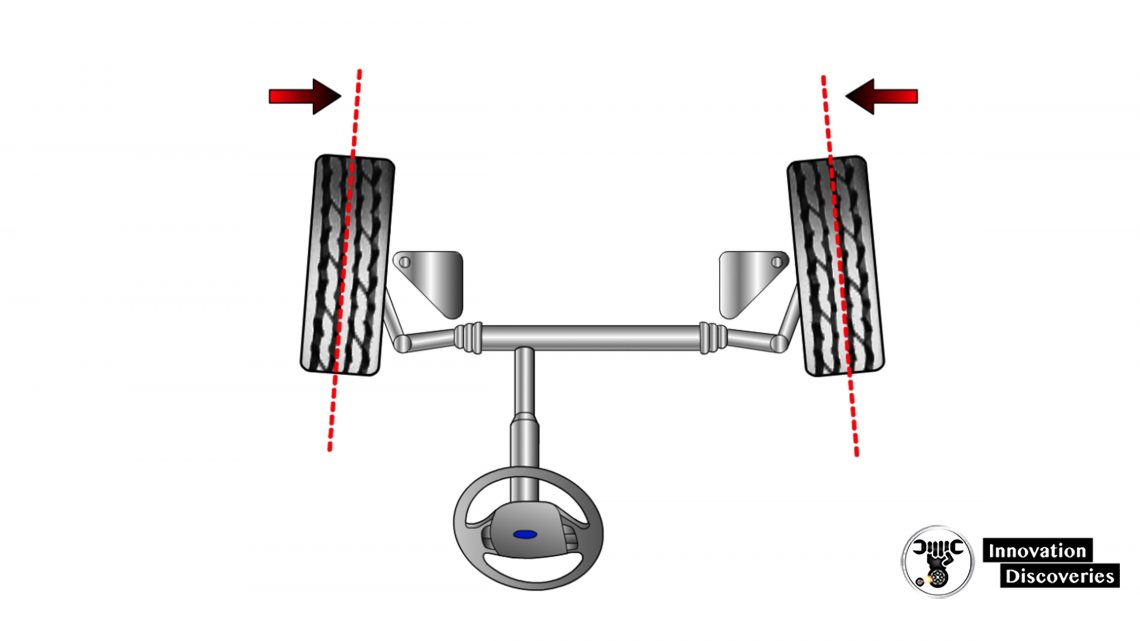

Toe Angle

- Inward or outward variation of tires from a straight-ahead position

- Toe-in is referred to as positive toe

- Toe out is referred to as negative toe

- Not a directional control angle

- Toe is a critical tire wear angle that commonly causes feathered tire tread wear

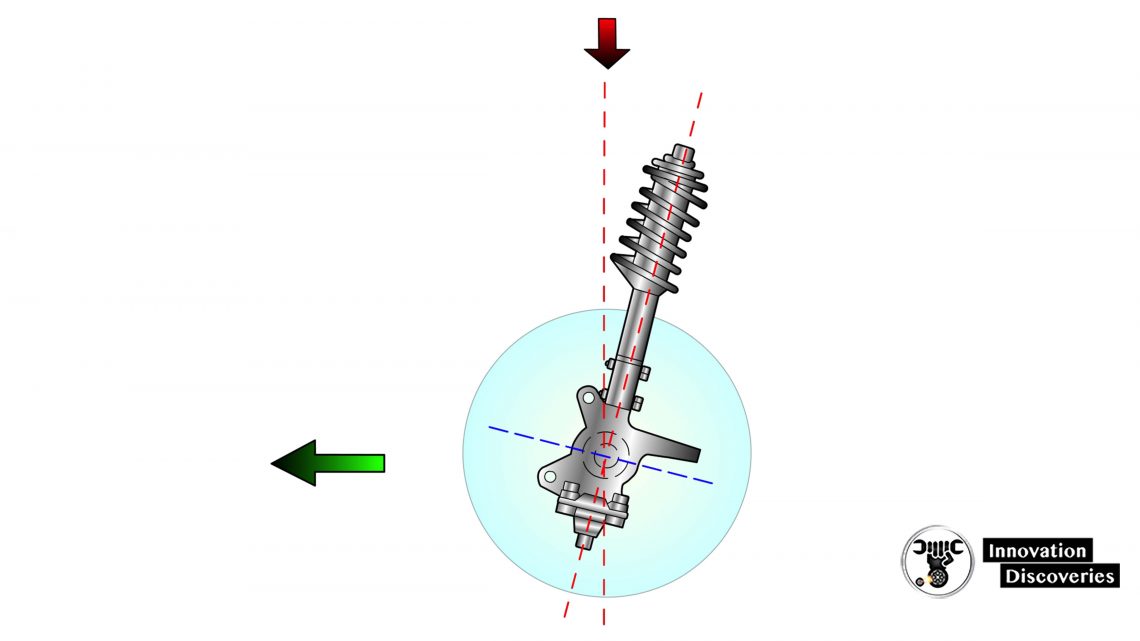

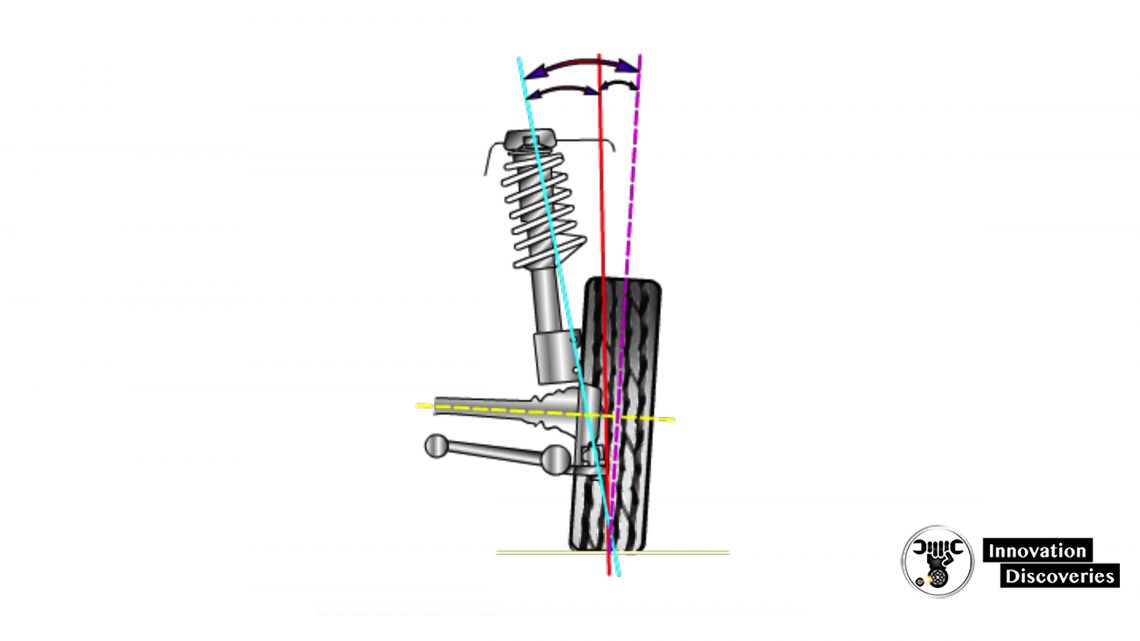

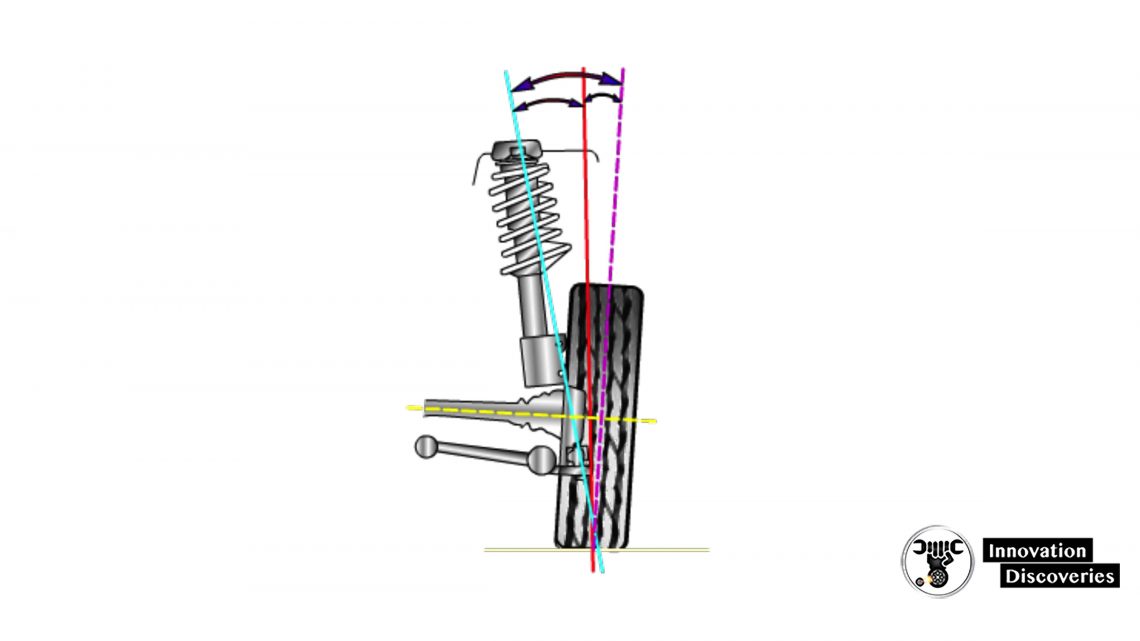

SAI and Included Angle

- SAI – Steering Axis Inclination

- The angle between the steering knuckle pivot points and true vertical

- Included Angle

- Sum of SAI and camber

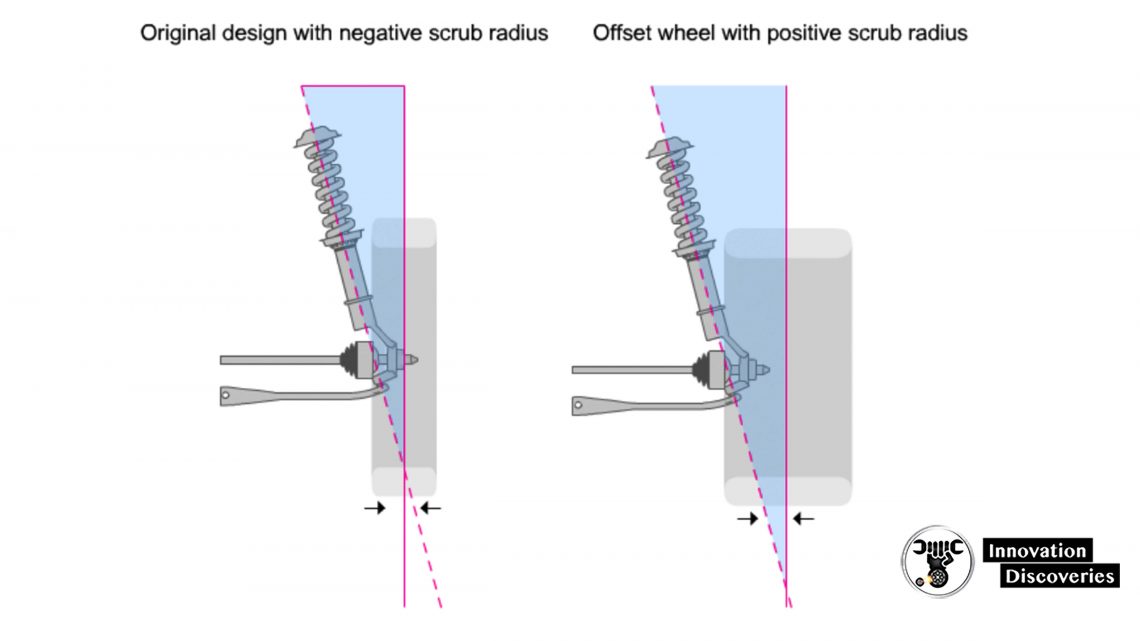

Scrub Radius

- Scrub radius is the distance between the tread centerline and the point where a projection of the steering axis angle would contact the road surface

Scrub Radius & Wheel Offset

Toe Out On Turns

- Toe out on turns is the difference in turning angles between the two front tires measured at a specific turning angle

- Customer concerns about toe out on turns are usually related to tire squealing during low-speed parking manoeuvres

- Improper toe out on turns is commonly caused by bent or damaged steering linkage and/or steering knuckles

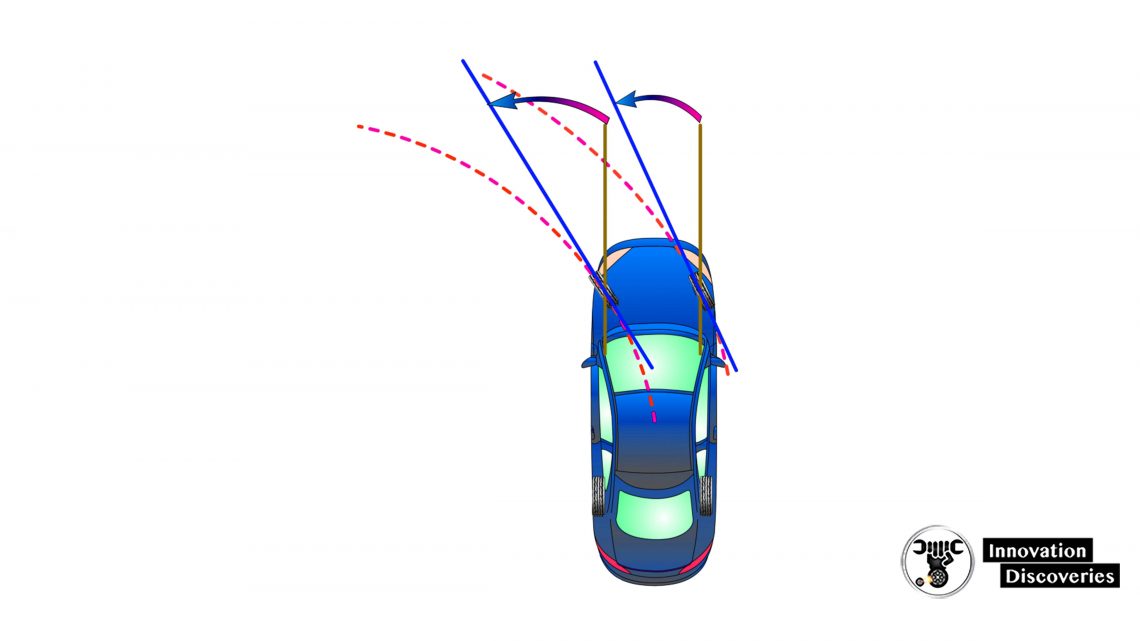

Thrust Angle

- Thrust angle is the difference between the centerline of the vehicle and the thrust line of the rear axle

- Negative – rear wheels point left

- Positive – rear wheels point right

Don’t Miss:

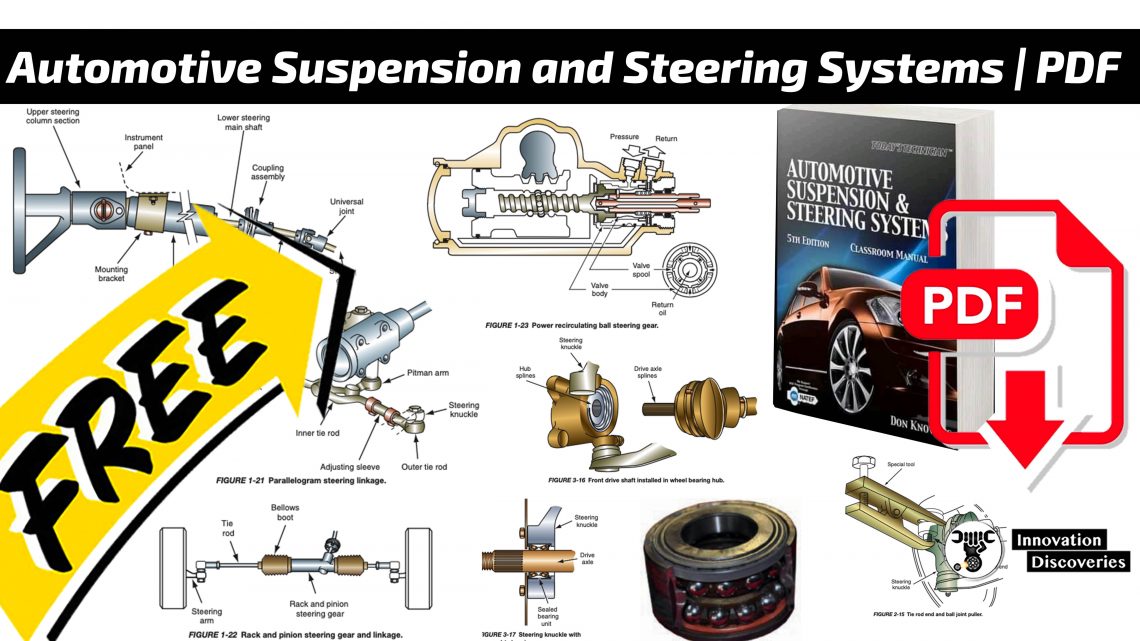

Suspension System

Suspension System Service

- Alignments are often considered part of routine vehicle maintenance

- A vehicle’s alignment should always be checked and adjusted after performing any steering or suspension system service that could impact alignment angles

- Proper wheel alignment affects vehicle handling, control, ride quality and tire life

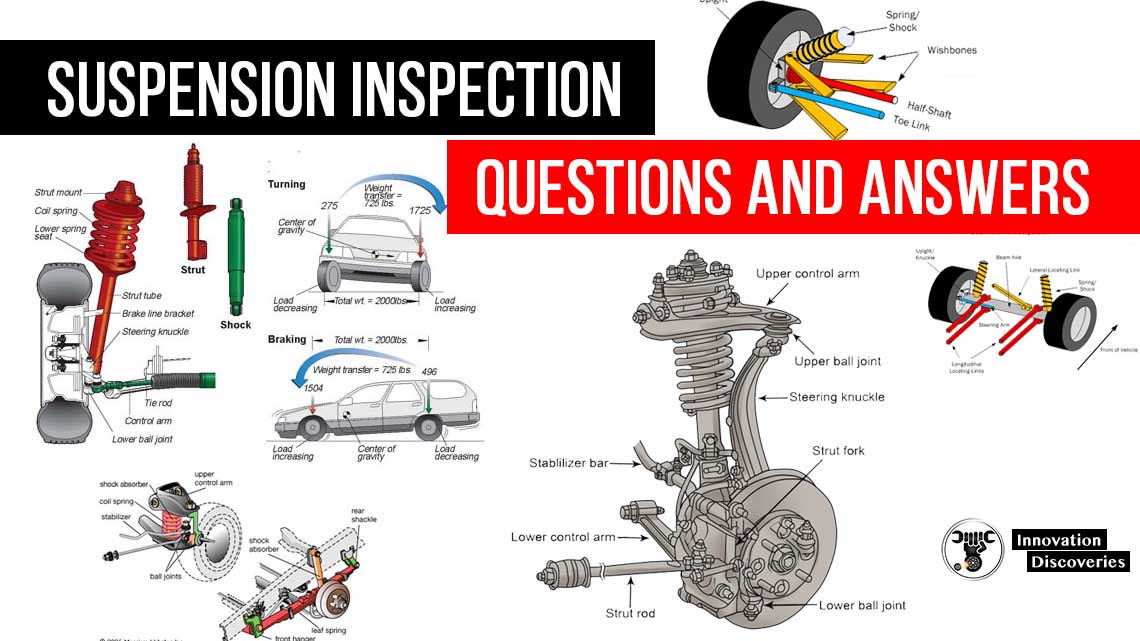

Alignment Pre-Checks

- Tire pressure and condition

- Evidence of recent collision damage

- Ride height

- Wheel bearings

- Steering linkage

- Suspension components

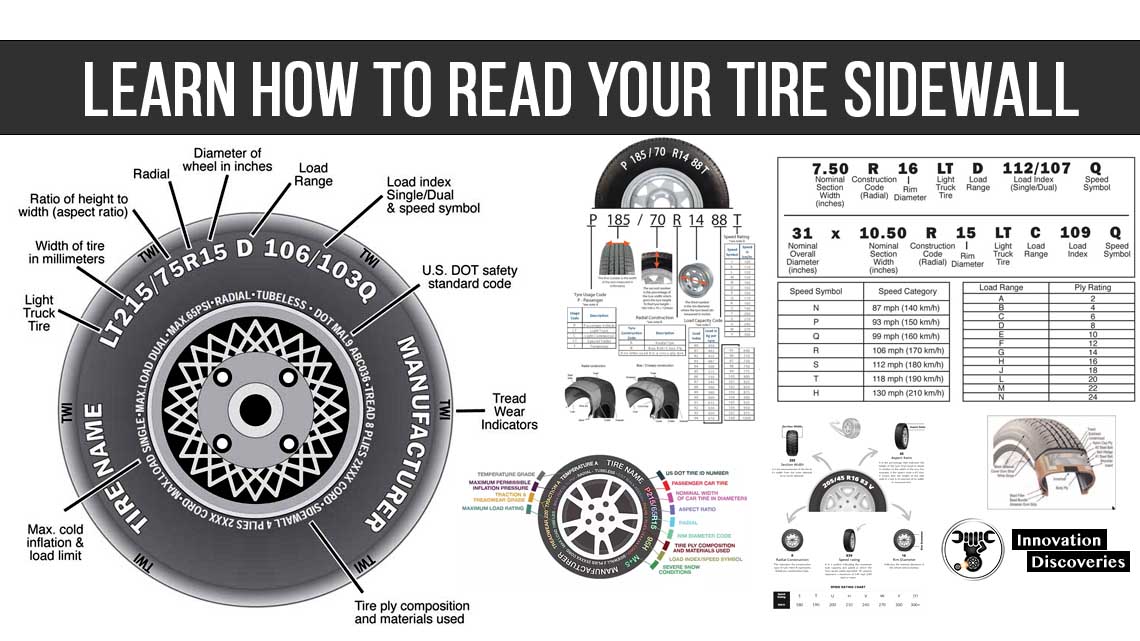

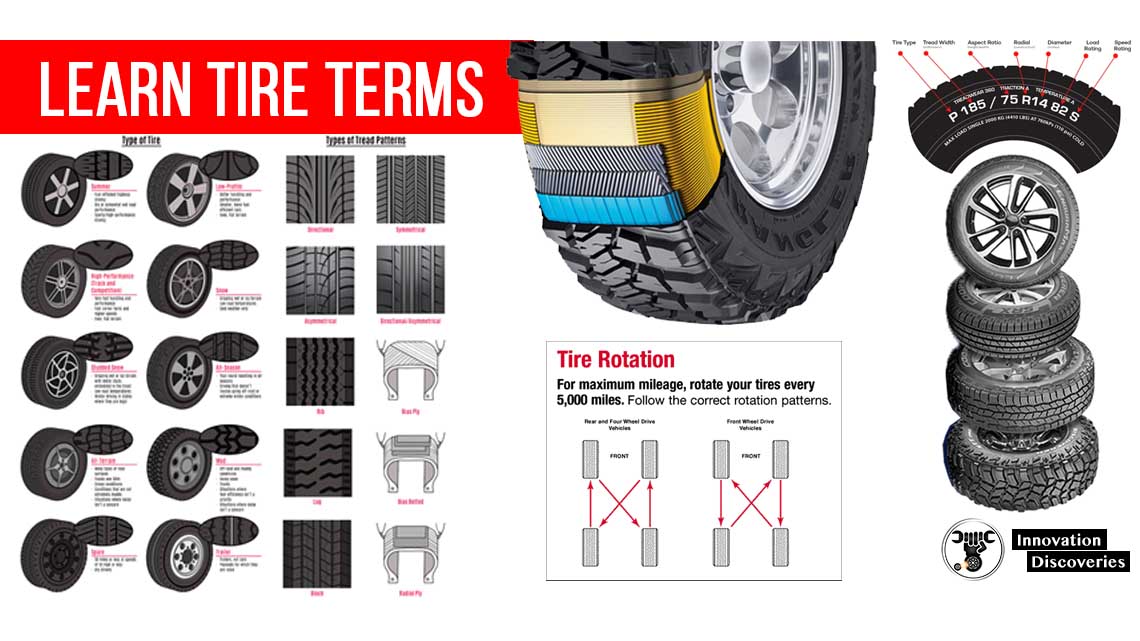

Tire Inspection

- Check and adjust tire pressure to the vehicle manufacturer’s specifications

- Inspect the tires for abnormal wear such as

- Center wear

- Wear on both outer edges

- Wear on one outer edge

- Feathering

- Cupping or damage

READ: Learn How to Read Your Tire Sidewall

Bearing Adjustment Inspection

- Wheel bearings should be inspected for proper adjustment or excessive wear

- Attempt to rock the tire from top to bottom

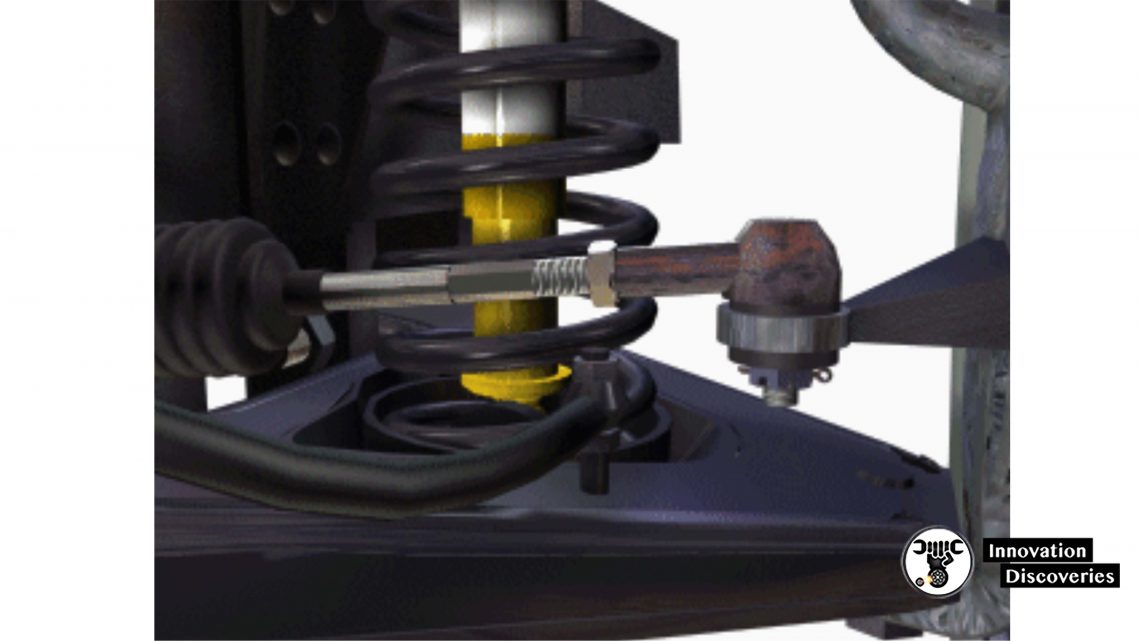

Steering Linkage Inspection

- The steering linkage should be inspected for excessive wear or damage

- Attempt to rock the tire from left to right

- Carefully inspect the linkage for evidence of damage

Suspension Inspection

- Inspect all bushings for evidence of damage, cracking and wear

- Inspect control arms, springs, ball joints, etc. for evidence of damage and wear

- Inspect shock absorbers and struts for leakage and damage

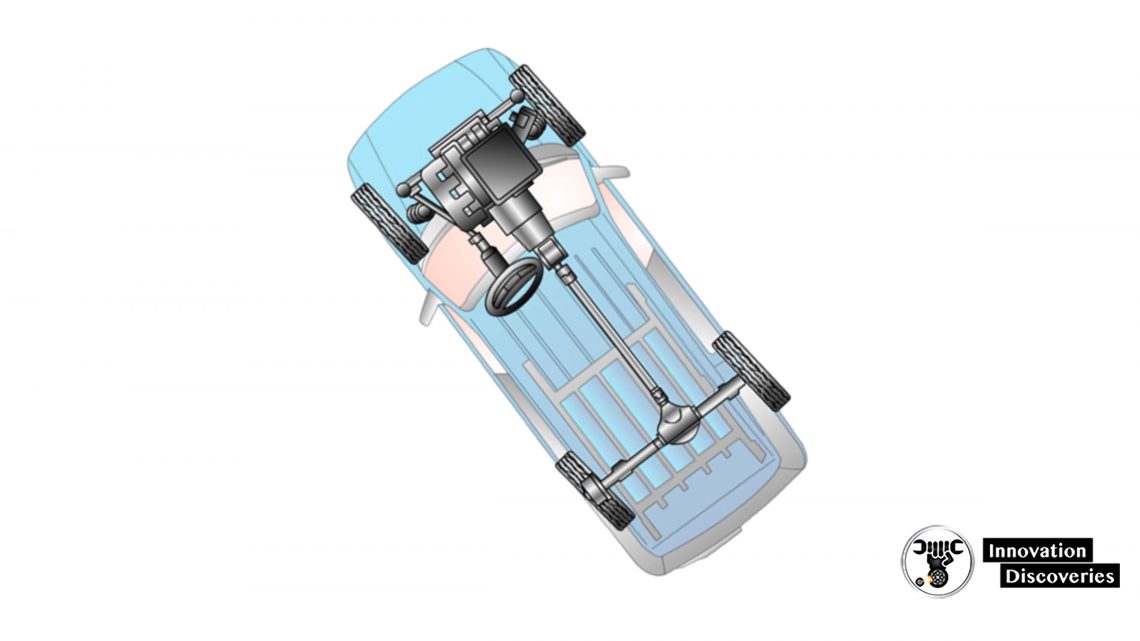

Types of Alignments

- Center line alignment

- The vehicle’s front wheels are aligned to the vehicle’s centerline

- Thrust angle alignment

- The vehicle’s front wheels are aligned to match the rear wheel’s thrust angle

- Four wheel alignment

- All four wheels are aligned to the vehicle’s centerline

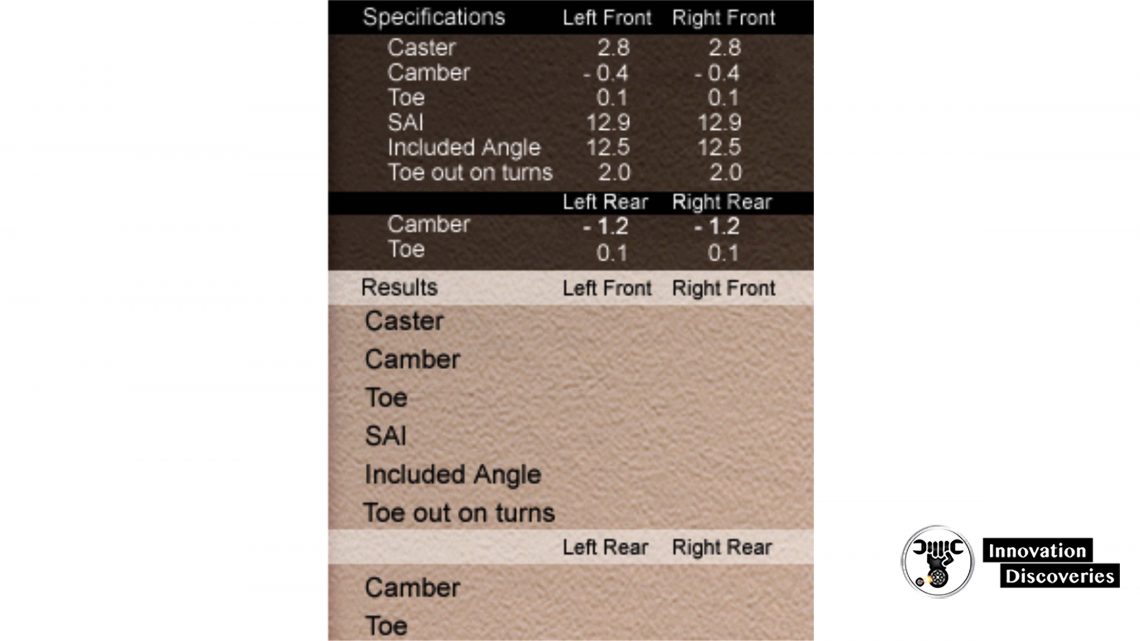

Alignment Procedure

- Perform alignment pre-checks

- Set up the alignment computer as per the equipment manufacturer’s instructions

- Mount and compensate the alignment sensor heads

- Measure caster

Alignment Adjustments

- Compare the alignment specifications to the vehicle’s actual settings and adjust in the following order

- Rear camber

- Rear toe

- Front caster

- Front camber

- Front toe

Camber and Caster Adjustment

- Camber is adjusted by moving the top of the tire inward or outward

- The caster is adjusted by moving the upper steering pivot point forward or backwards

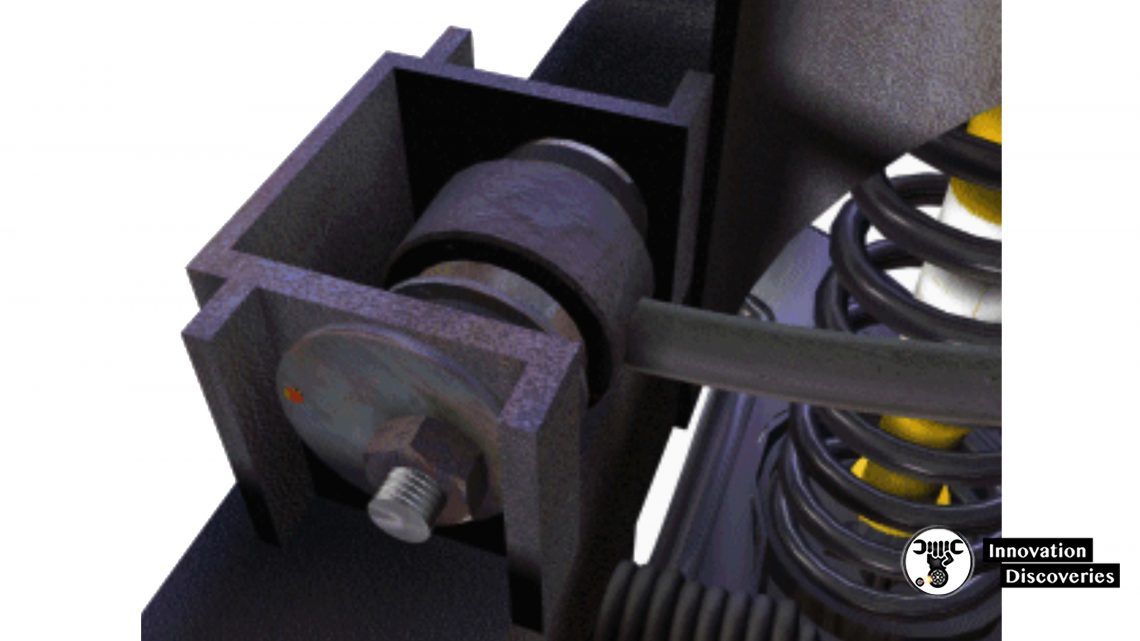

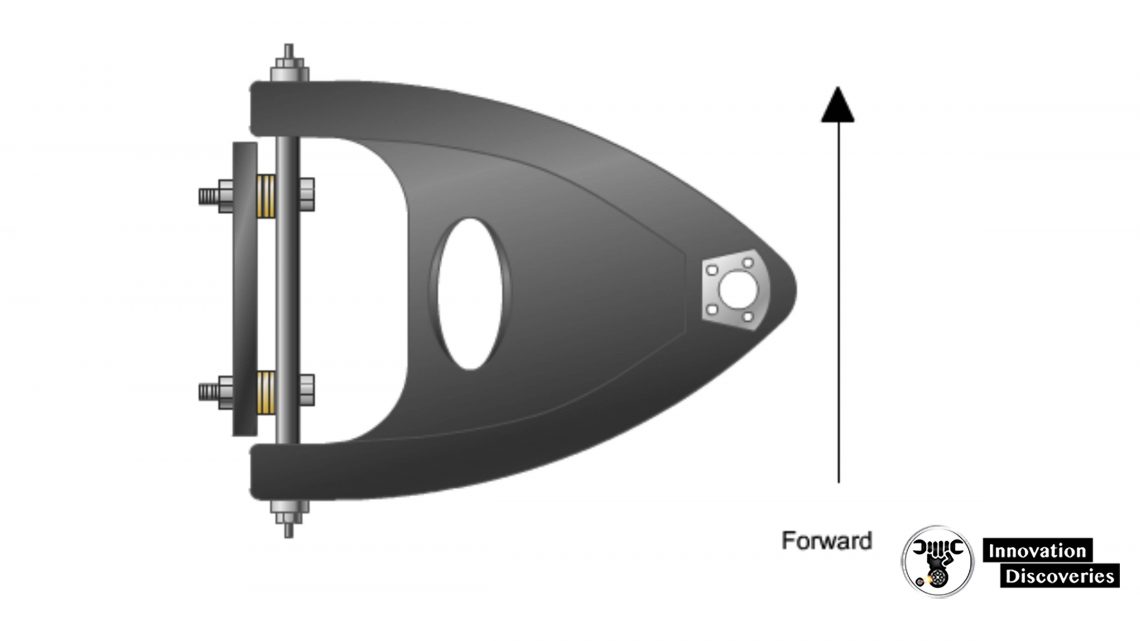

Control Arm Shims

- Adding shims between the control arm and frame as shown moves the upper ball joint inward

- Changing the shim pack dimensions allows the technician to change the caster and camber

- Some vehicles use shims to move the control arm outward

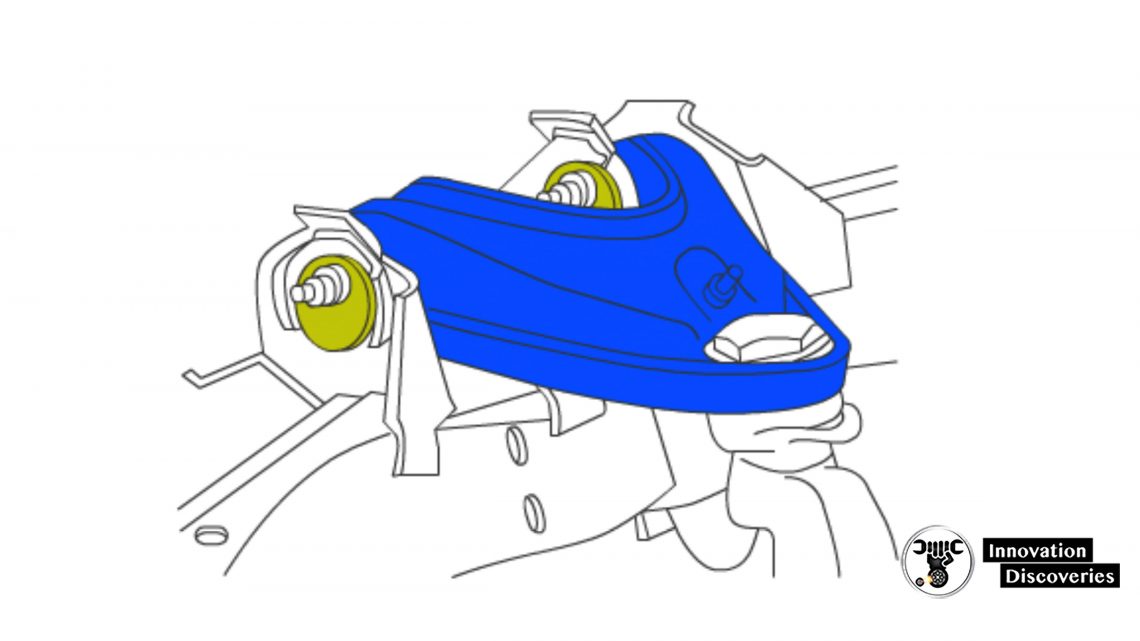

Moveable MacPherson Strut

- Elongated strut mounting holes may allow the strut to be moved to change the caster and/or camber

- Some vehicles require you to rotate the strut in mount holes to make changes in the caster and/or camber

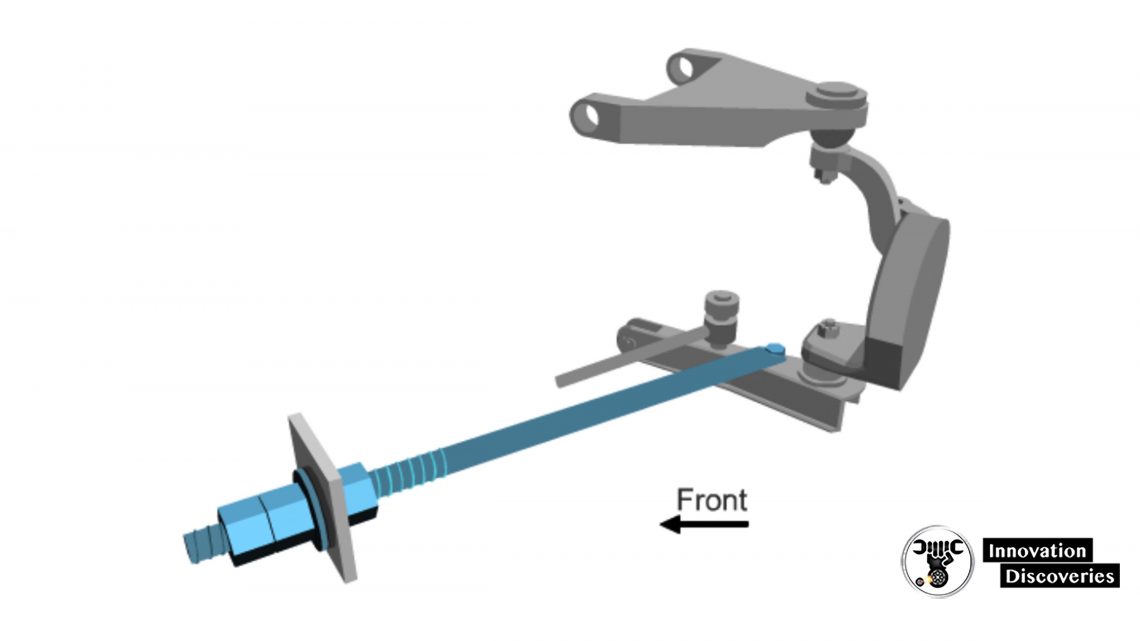

Adjustable Strut Rod

- Change strut rod length moves the lower ball joint to be shifted forward and rearward

- Moving the lower ball joint forward increases the caster

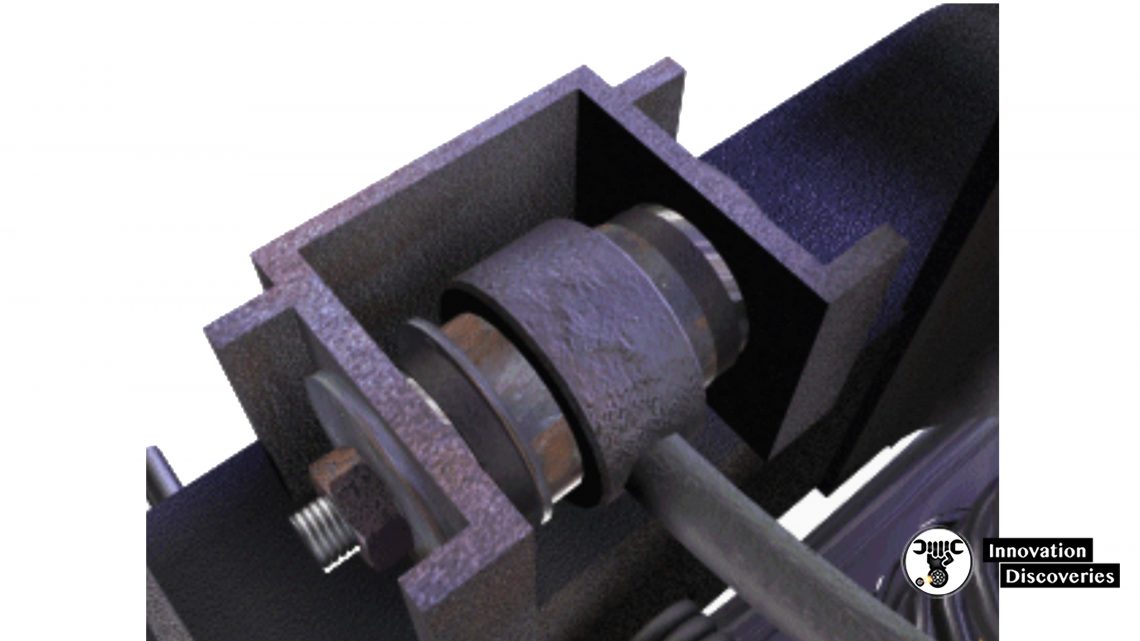

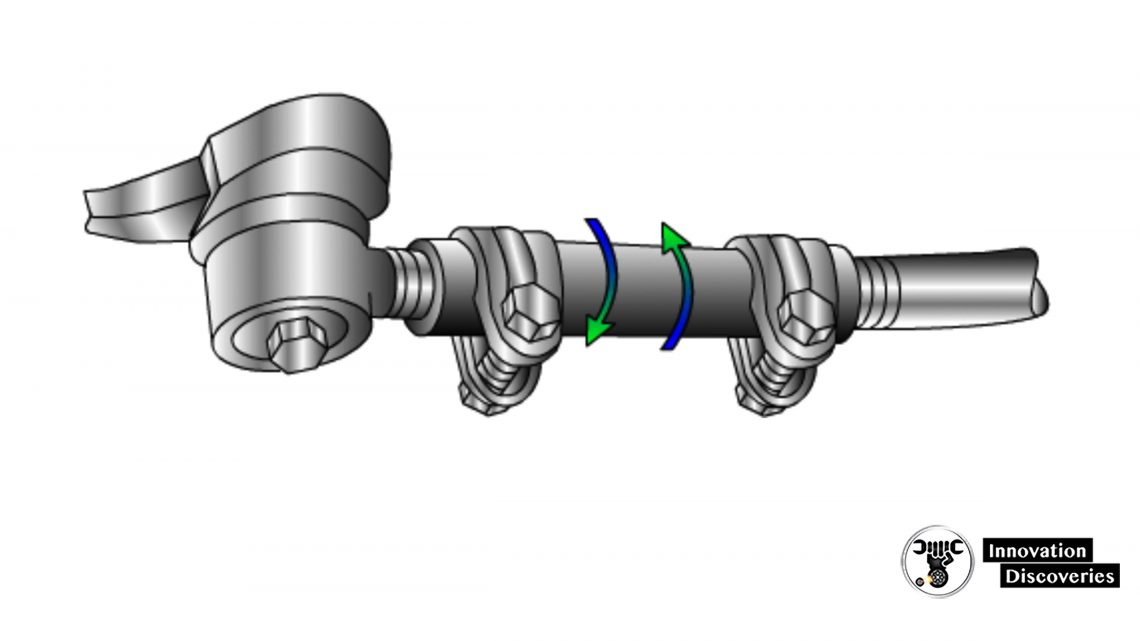

Control Arm Cams

- Eccentric cams allow the technician to move the upper ball joint in and out

- Moving both eccentrics equally changes only camber

- Moving one cam in and the other cam out an equal amount changes only the caster

Toe Adjustment

- Toe is adjusted to set the tires parallel to one another while the vehicle is moving

- Toe is adjusted by increasing or decreasing the tie rod length

Toe Adjustment Procedure

- Set the steering wheel straight ahead and lock the wheel

- Parallelogram

- Loosen the clamps

- Rotate the adjuster sleeve

- Tighten the clamps

- Rack and pinion

- Loosen the tie rod end lock nut

- Rotate tie rod

- Tighten tie rod end lock nut

DISCOVER MORE:

READ MORE:

- A QUICK GUIDE TO DIAGNOSING 10 COMMON STEERING ISSUES

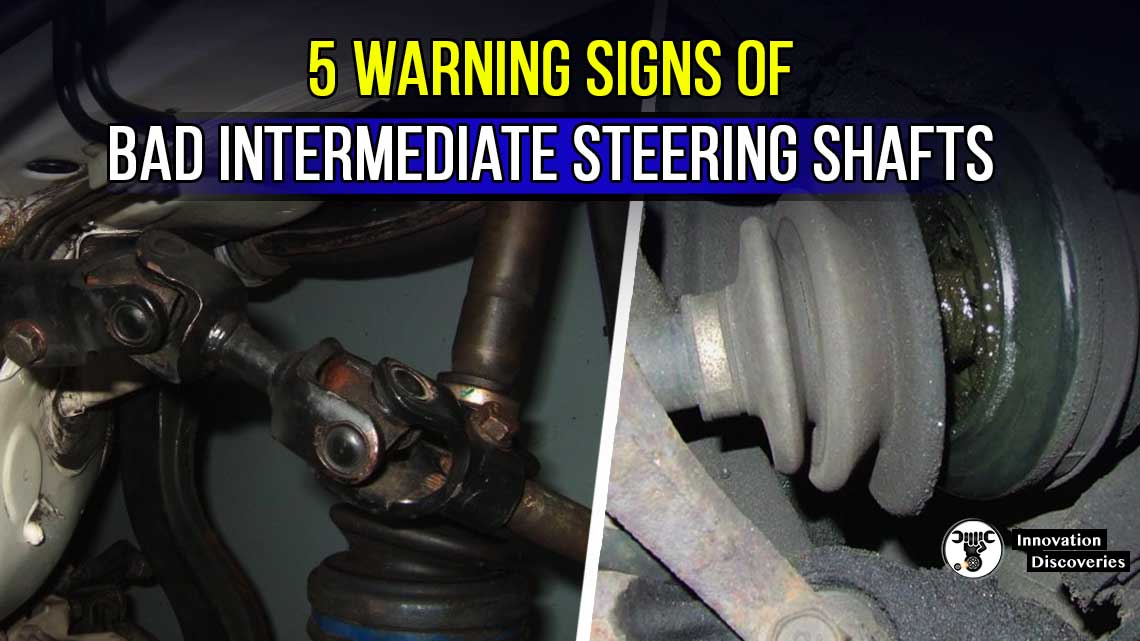

- 5 WARNING SIGNS OF BAD INTERMEDIATE STEERING SHAFTS

- 3 COMMON SYMPTOMS OF LOW POWER STEERING FLUID

- ELECTRIC VS HYDRAULIC POWER STEERING

- HOW POWER STEERING WORKS?

- STEERING SYSTEM: REQUIREMENTS, TYPES, POWER STEER

Visit Forum

Visit Our Friendly Website