Introduction

Direct injection carbon build-up is a common issue that many modern gasoline engines equipped with direct fuel injection systems face.

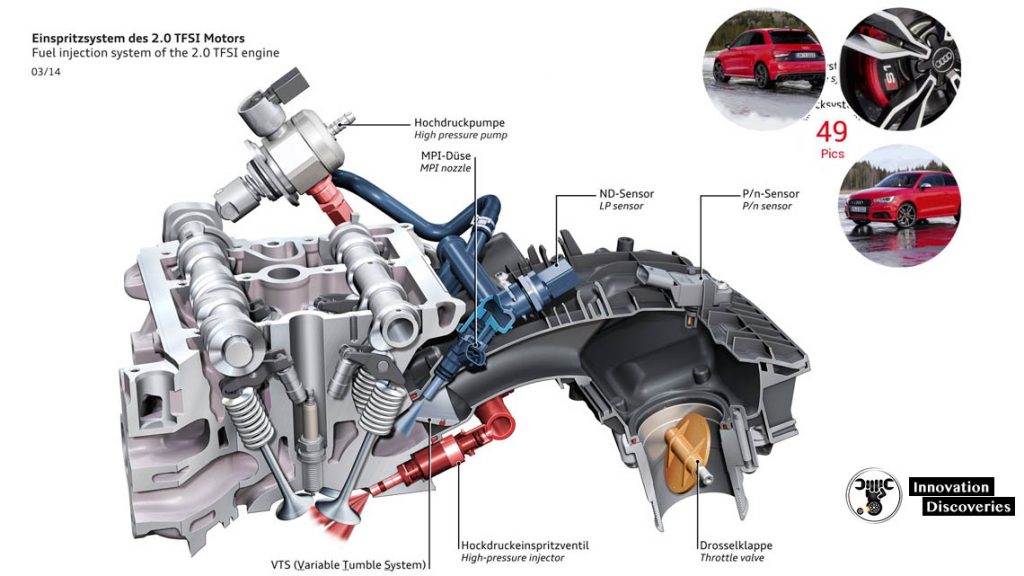

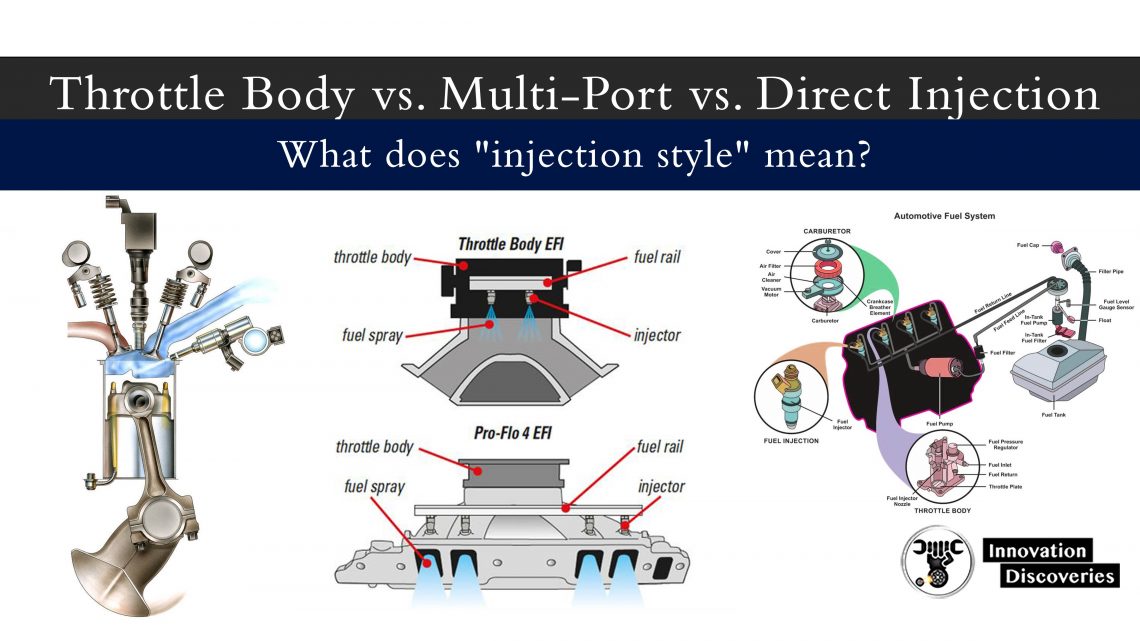

Unlike traditional port fuel injection systems, where fuel is injected before the intake valve, direct injection systems spray fuel directly into the combustion chamber.

While this technology offers benefits such as improved fuel efficiency and performance, it also poses challenges, one of which is carbon build-up.

Why It Happens?

1. Unable to Clean Valve and Port:

In traditional port fuel injection systems, fuel passes through the intake valve, which helps keep the valve and port clean from carbon deposits.

However, in direct injection systems, fuel is injected directly into the combustion chamber, bypassing the intake valve.

This lack of fuel washing over the intake valves allows carbon deposits to accumulate over time.

2. High Combustion Pressure:

Direct injection engines typically operate at higher combustion pressures than port fuel injection engines.

This elevated pressure can contribute to increased carbon build-up, as it leads to more intense heat and pressure inside the combustion chamber, which can cause carbon deposits to form on the intake valves and other engine components.

Note: Even the air passing through the valve is not hot enough to burn these byproducts.

3. Another Cause:

There may be other contributing factors to direct injection carbon build-up, such as poor-quality fuel, driving habits, or engine design.

However, the lack of fuel washing over the intake valves and the higher combustion pressures are primary factors.

SEE MORE:

- Engine Braking With A Manual Transmission – Is It Bad?

- Wondering “Why Are Diesel Engines Noisy?” The Reasons

Symptoms of Direct Injection Carbon Build Up:

- Reduced engine performance

- Rough idle

- Misfires

- Increased fuel consumption

- Engine knocking or pinging

- Check engine light illuminated

How to Prevent Direct Injection Carbon Build Up?

There are indeed three best possible ways you can try:

1. Regular Maintenance

One of the most effective ways to prevent carbon build-up in direct injection engines is through regular maintenance.

This includes following the manufacturer’s recommended service intervals for oil changes, air filter replacements, and other routine maintenance tasks.

2. Spark Plug Replacement

Worn or fouled spark plugs can contribute to inefficient combustion, which can lead to increased carbon build-up.

Replacing spark plugs at the recommended intervals can help maintain optimal engine performance and reduce the risk of carbon deposits forming.

3. Clean Up of Fuel Injectors

Over time, fuel injectors can become clogged or dirty, affecting fuel delivery and combustion efficiency.

Periodically cleaning or flushing the fuel injectors can help prevent carbon build-up and ensure proper fuel atomization.

Conclusion

Direct injection carbon build-up is a common issue faced by modern gasoline engines, but it can be mitigated with proper maintenance and preventive measures.

By following the recommended maintenance schedule, replacing spark plugs as needed, and cleaning fuel injectors regularly, drivers can help prevent carbon deposits from accumulating and ensure their engines continue to run smoothly and efficiently.

Regular inspection and maintenance are key to keeping direct injection engines performing at their best and minimizing the risk of costly repairs down the road.

Check out the video:

Understand deeply about Why direct injections have problems with carbon:

Hopefully, through this post, you will learn more about Direct Injection Engine carbon build-up and solutions to clean them off the valves.

Read More:

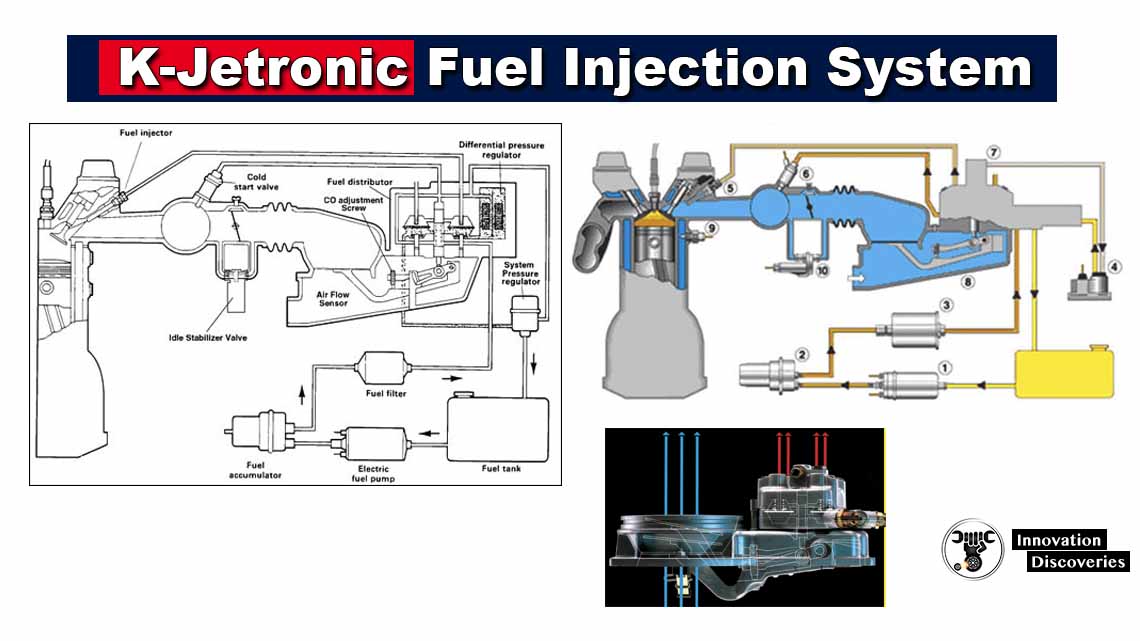

- K-JETRONIC FUEL INJECTION SYSTEM

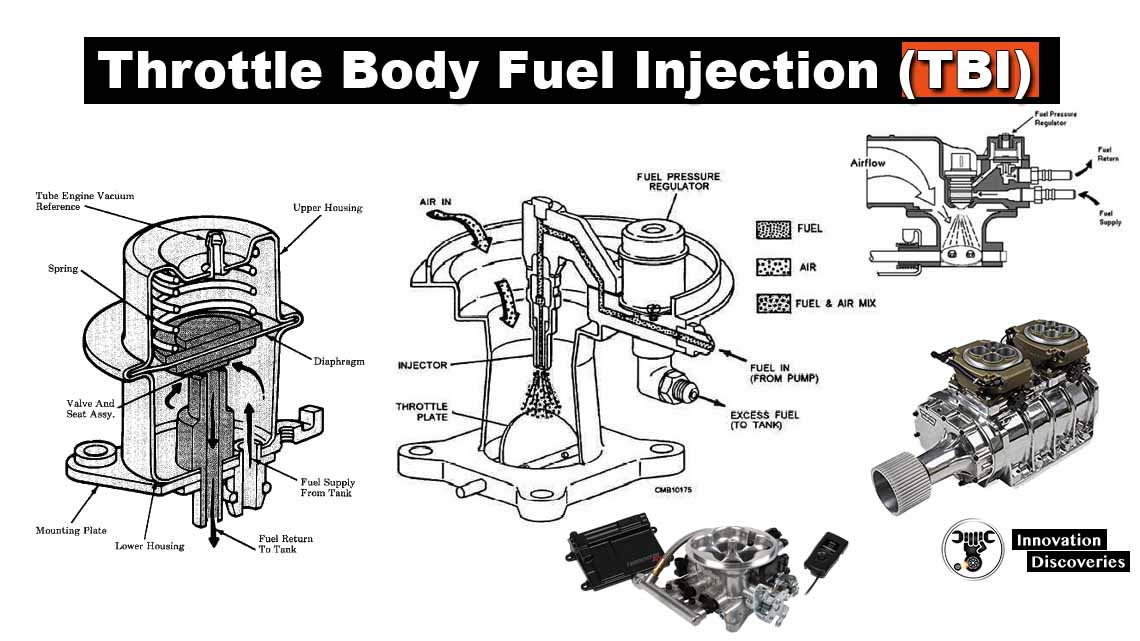

- THROTTLE BODY FUEL INJECTION

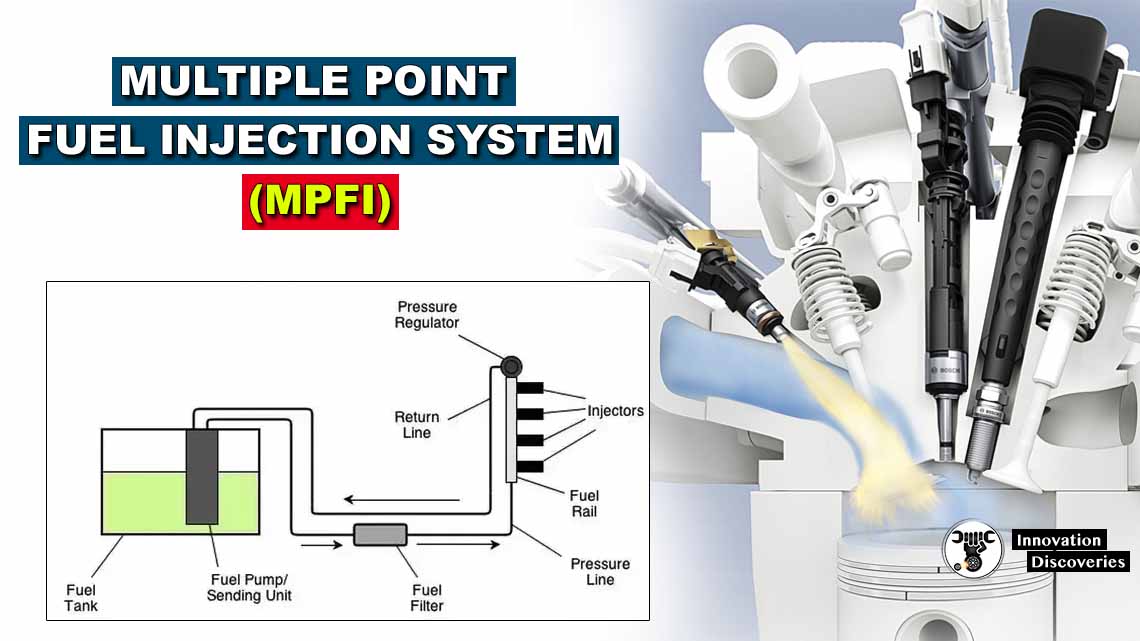

- WHAT IS MULTIPLE POINT FUEL INJECTION(MPFI)?

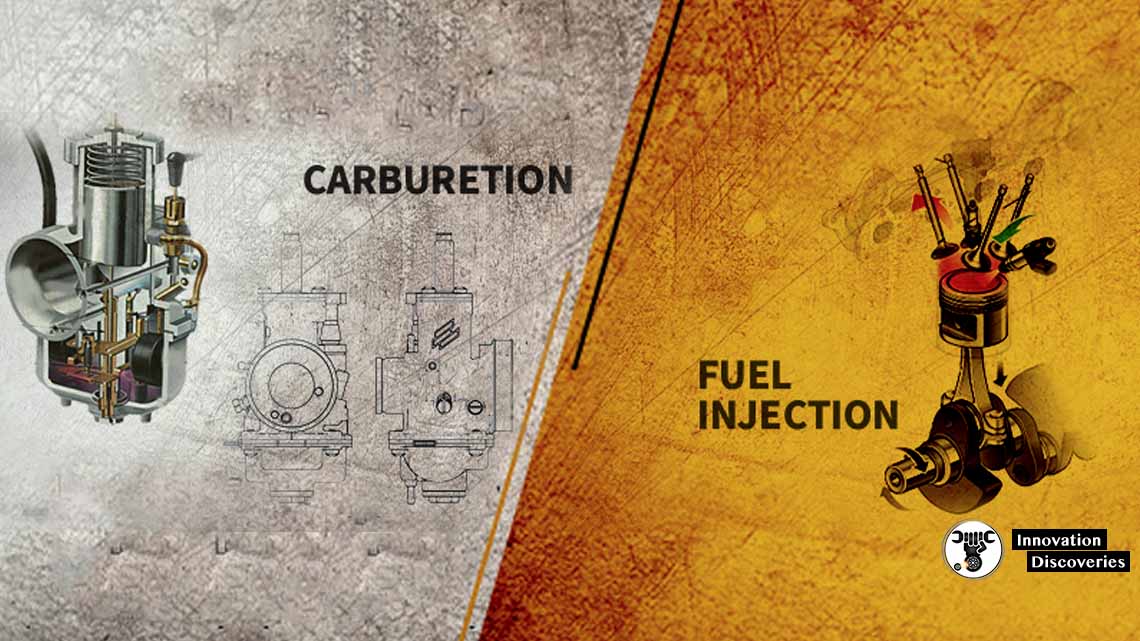

- CARBURETOR VS FUEL INJECTION: WHICH ONE IS THE BETTER OPTION?

Discover More:

Visit Forum

Visit Our Friendly Website