Continuously Variable Transmission (CVT) is a type of automatic transmission that provides seamless and stepless gear ratio changes, allowing for a smooth acceleration without discrete gear shifts. Unlike traditional automatic transmissions with a fixed number of gears, CVTs offer an infinite number of gear ratios within a certain range, enabling the engine to operate at its most efficient point for a given driving condition.

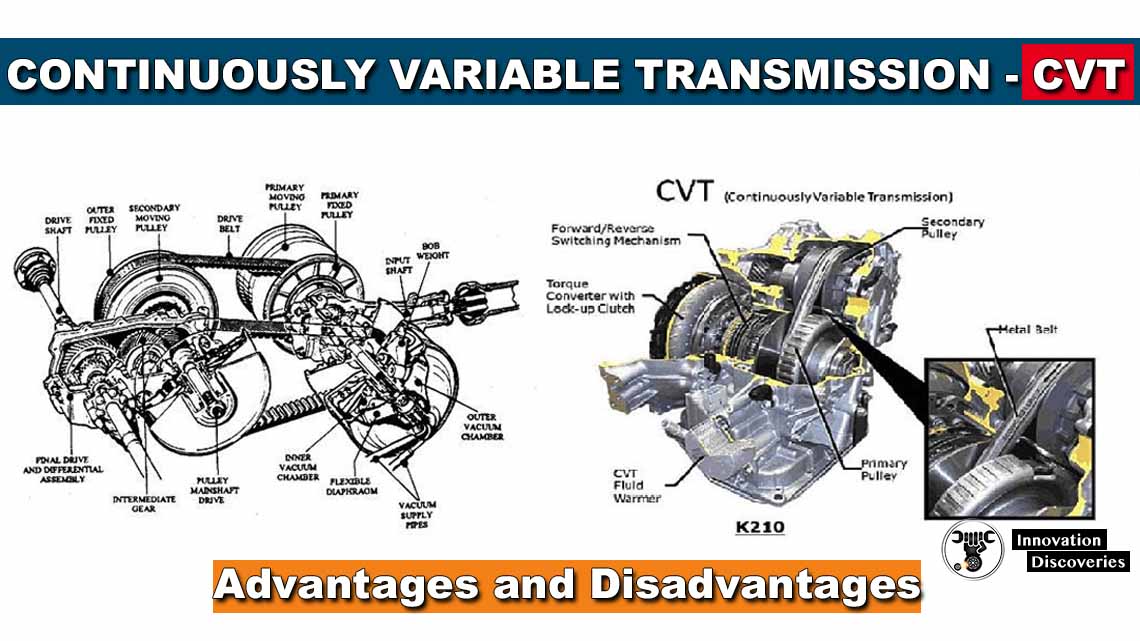

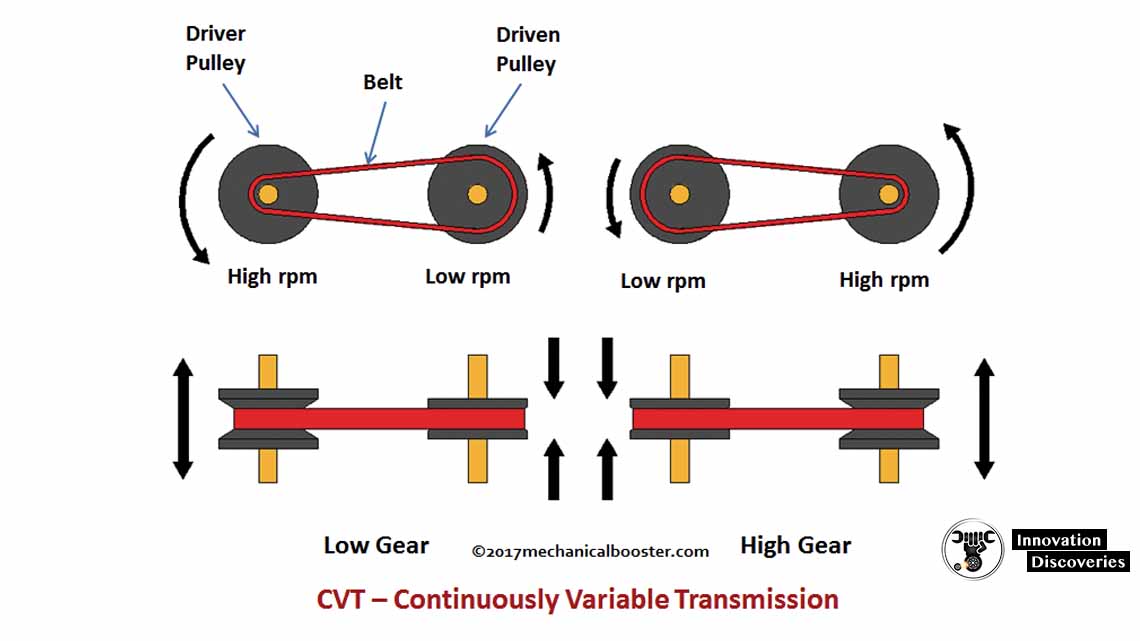

The main components of a CVT include a belt or chain, variable-width pulleys, and a control system. The belt or chain connects two variable-width pulleys—one connected to the engine and the other to the wheels. By adjusting the width of the pulleys, the effective diameter changes, altering the gear ratio.

In a CVT, as the vehicle accelerates, the pulleys gradually change their effective diameters to maintain the optimal engine speed for efficiency and power delivery. This allows the engine to operate at its peak performance range, resulting in improved fuel economy and smoother driving experience.

CVTs have several advantages over traditional transmissions. They provide better fuel efficiency since the engine can always operate at its most efficient RPM. The smooth and continuous power delivery eliminates the jerkiness associated with gear shifts, enhancing the driving comfort.

Additionally, CVTs are generally lighter and simpler in design compared to conventional transmissions.

However, CVTs also have some limitations. One common criticism is the “rubber band” effect, where the engine revs high under heavy acceleration but the vehicle speed doesn’t increase at the same rate, leading to a disconnected feeling. This effect has been mitigated in modern CVTs with advanced control algorithms. Furthermore, earlier CVTs had limited torque capacity, but newer designs have addressed this issue, allowing for higher torque applications.

CVTs are commonly found in small to mid-sized vehicles, hybrids, and some sports cars. They continue to evolve with advancements in technology, such as adaptive control systems and artificial intelligence, which further optimize the transmission’s performance and efficiency.

Advantages of Continuous Variable Transmission System:

(a) Design Factor:

CVTs are generally lighter and simpler in design compared to conventional transmissions. They have fewer moving parts, which can result in reduced weight, improved packaging, and easier integration into vehicles.

(b) Acceleration Advantage:

CVTs provide a smoother and more seamless acceleration compared to traditional transmissions. As there are no discrete gear shifts, the engine can continuously operate at its optimal RPM, delivering smooth and linear power delivery. This can result in improved acceleration performance.

(b) Acceleration Advantage: CVTs provide a smoother and more seamless acceleration compared to traditional transmissions. As there are no discrete gear shifts, the engine can continuously operate at its optimal RPM, delivering smooth and linear power delivery. This can result in improved acceleration performance.

(c) Fuel Efficiency:

One of the significant advantages of CVTs is their ability to optimize the engine’s efficiency. By continuously adjusting the gear ratio, the engine can operate at its most efficient RPM for a given driving condition. This can lead to improved fuel efficiency and reduced emissions.

Disadvantages of Continuous Variable Transmission System:

(a) Limited Torque Handling:

Traditional CVTs have had limitations in handling high torque outputs, which makes them less suitable for high-performance or heavy-duty applications. However, newer designs and technologies have improved the torque-handling capabilities of CVTs, making them more viable for a wider range of applications.

(b) Quality of Drive:

Some drivers may find the driving experience with CVTs to be less engaging or less connected compared to traditional transmissions. This perception is often due to the “rubber band” effect, where the engine revs high under heavy acceleration but the vehicle speed doesn’t increase at the same rate. However, modern CVTs are equipped with advanced control algorithms that minimize this effect and provide a more refined driving experience.

(c) The Cost Factor:

CVTs can be more expensive to manufacture and repair compared to traditional transmissions. The complexity of the design, the use of advanced materials, and the need for specialized maintenance and repair equipment can contribute to higher costs. However, as CVTs become more common and technology advances, the cost difference is gradually decreasing.

It’s worth noting that the advantages and disadvantages mentioned above are generalizations and can vary depending on the specific design and implementation of the CVT system. Manufacturers continue to improve CVT technology to address these limitations and enhance their overall performance and reliability.

Don’t miss

Also read: (click to image for read)

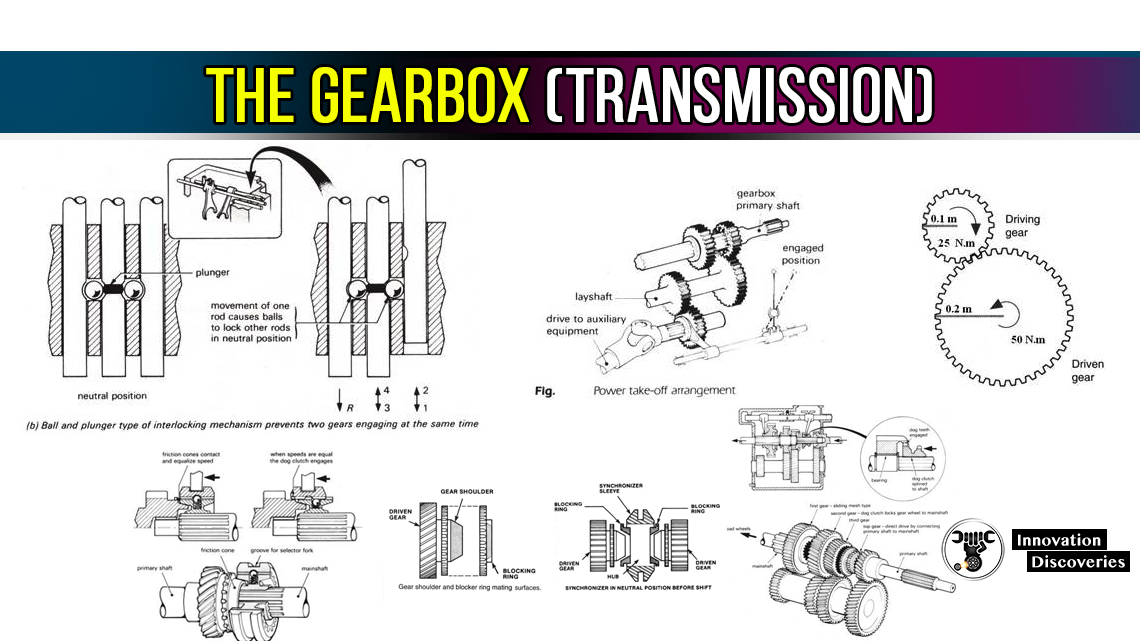

READ: WHAT ARE THE MAIN COMPONENTS OF THE GEAR BOX?

2 Comments