Learning Objectives:

- Recognize the corresponding components of the cooling system.

- Understand the working principles of the cooling system.

- Understand the function of a radiator

Apparatus: Diesel Engine Test Bed

Theory:

Combustion of the air-fuel mixture in the cylinders generates heat which produces high pressure, to force the piston down in the power stroke.

Not all of this heat can be converted into useful work on the piston, and it must be removed to prevent the seizure of moving parts.

This is the role of the cooling system. Most engines are liquid-cooled.

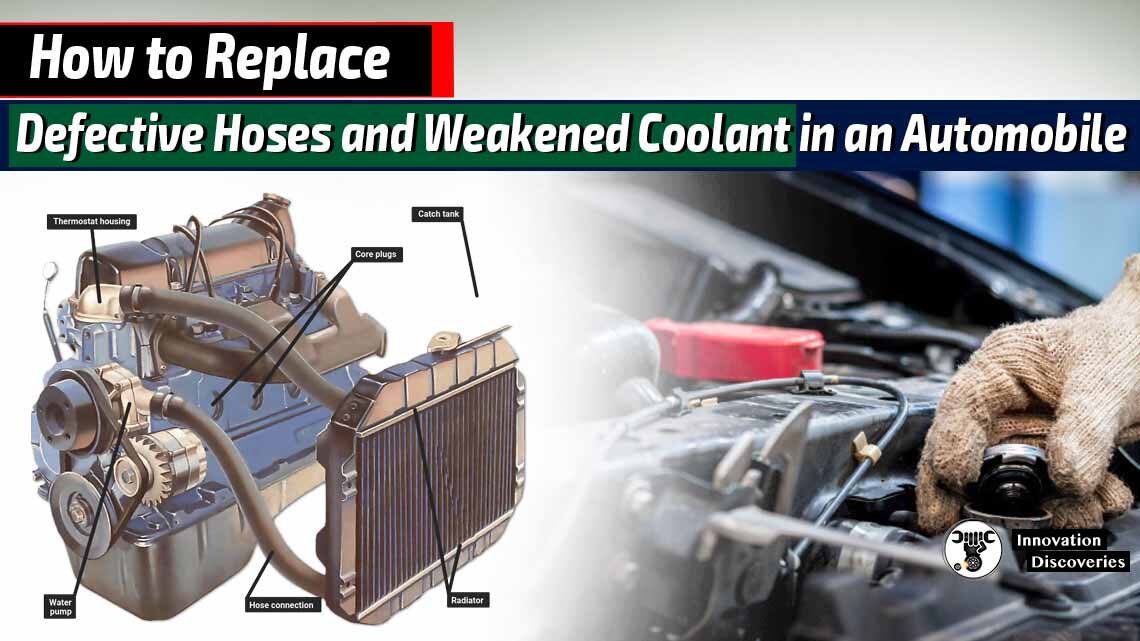

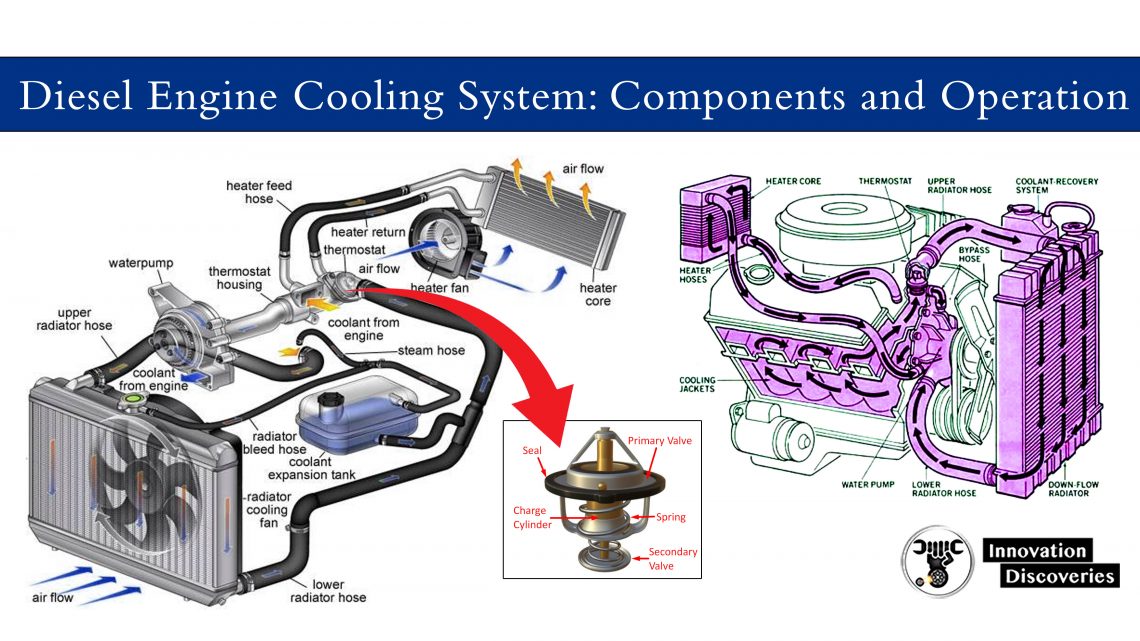

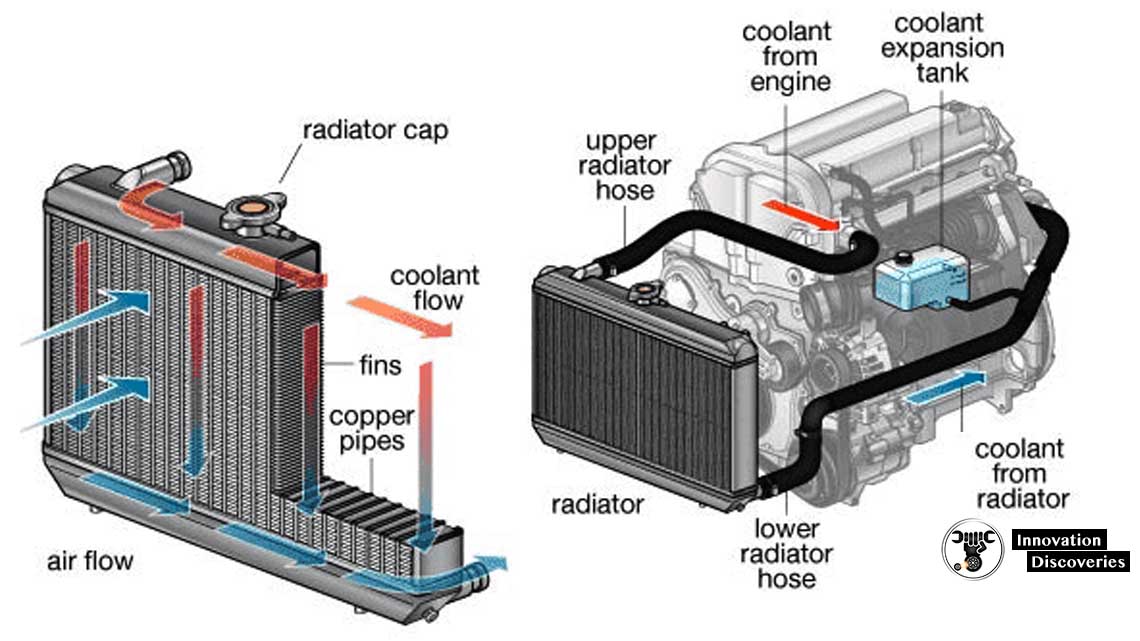

A liquid-cooled system uses water coolant. Basically, coolant flows through passages in the engine and through a radiator.

The radiator accepts hot coolant from the engine and lowers its temperature. Air flowing around, and through the radiator takes heat from the coolant.

COMPONENTS OF A COOLING SYSTEM

- The Radiator

- Radiator Cooling Fans

- Pressure Cap & Reserve Tank

- Water Pump

- Thermostat

- Bypass System

- Freeze Plugs

- Head Gaskets & Intake Manifold Gaskets

Radiator:

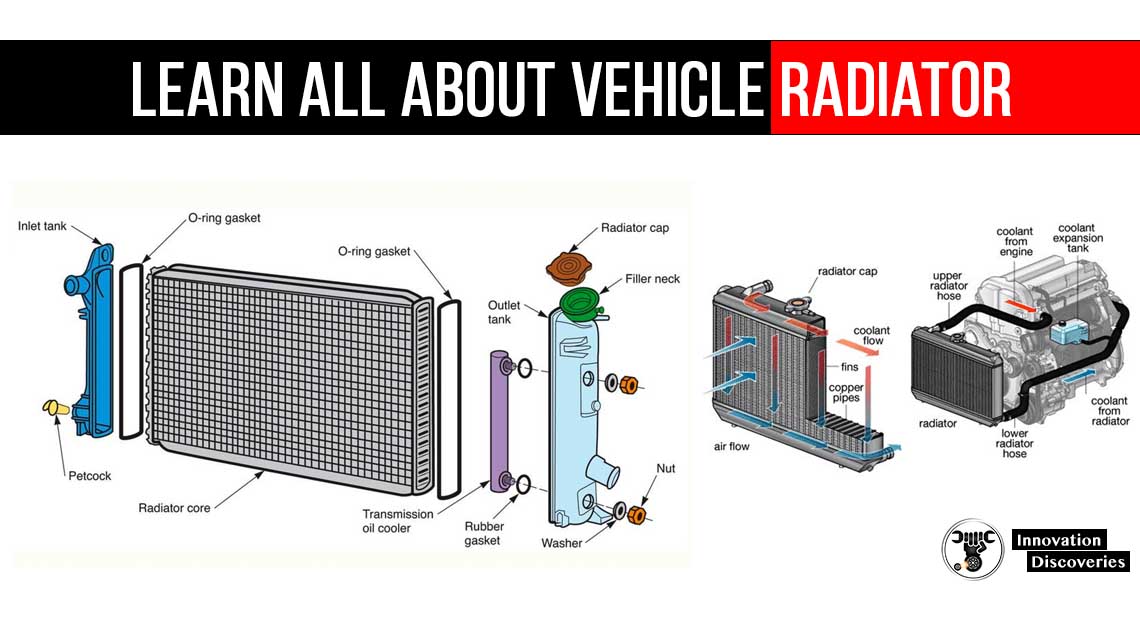

The radiator core is usually made of flattened aluminium tubes with aluminium strips that zigzag between the tubes.

These fins transfer the heat in the tubes into the air stream to be carried away from the vehicle.

On each end of the radiator core is a tank, usually made of plastic, that covers the ends of the radiator.

Radiator Fan:

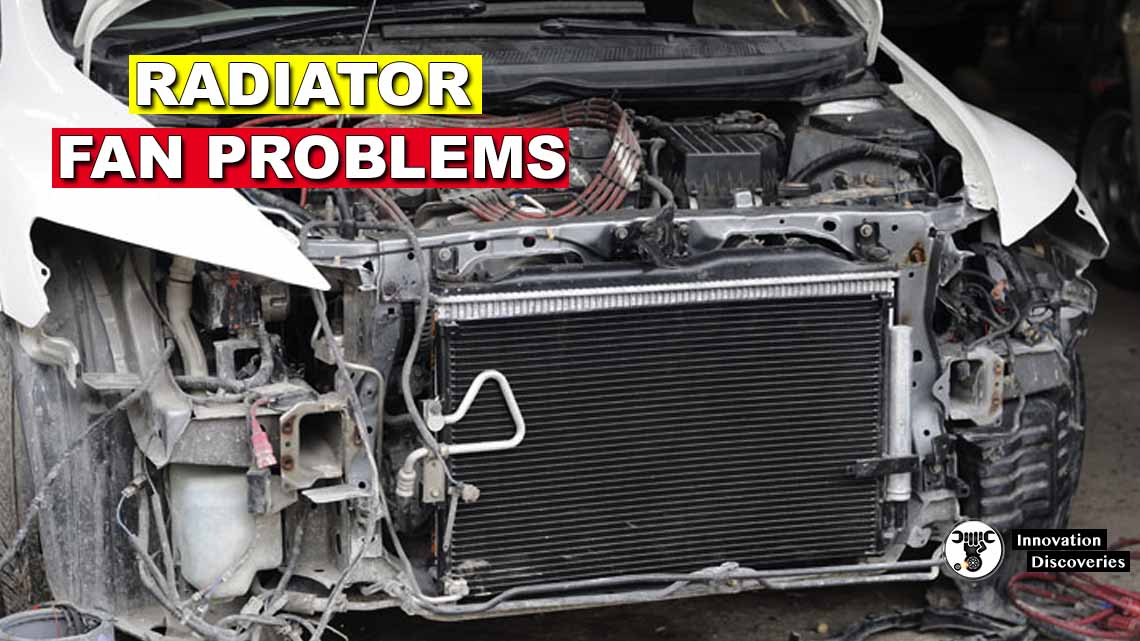

Mounted on the back of the radiator on the side closest to the engine, inside a housing that is designed to protect fingers and direct the airflow.

These fans are there to keep the airflow going through the radiator while the vehicle is going slow or is stopped with the engine running.

If these fans stopped working, every time you came to a stop, the engine temperature would begin rising.

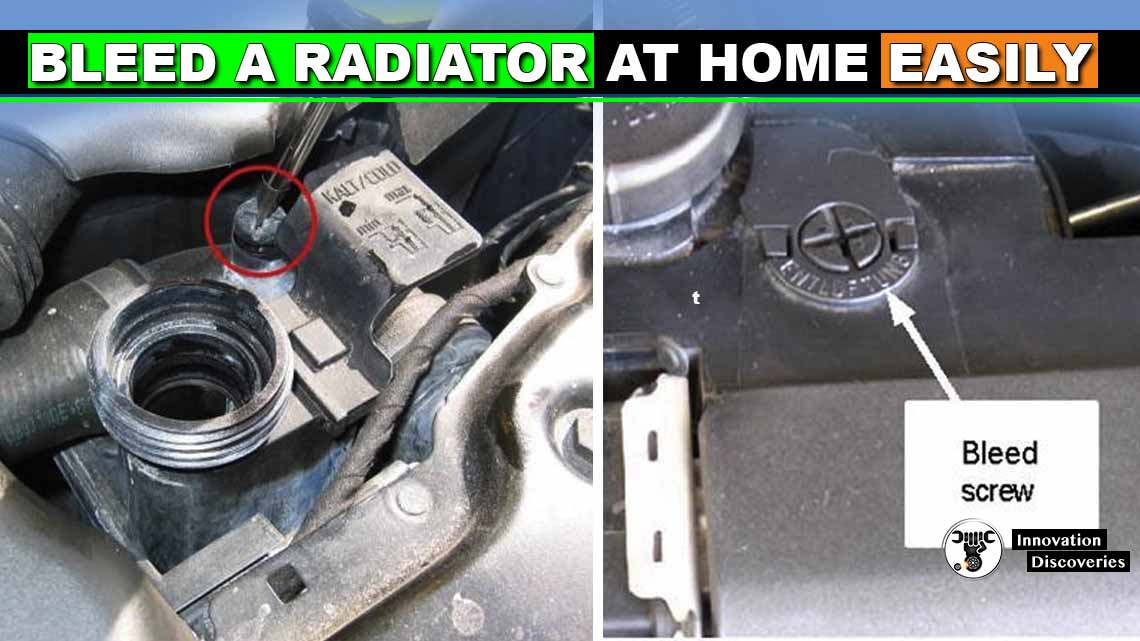

Pressure cap and reserve tank

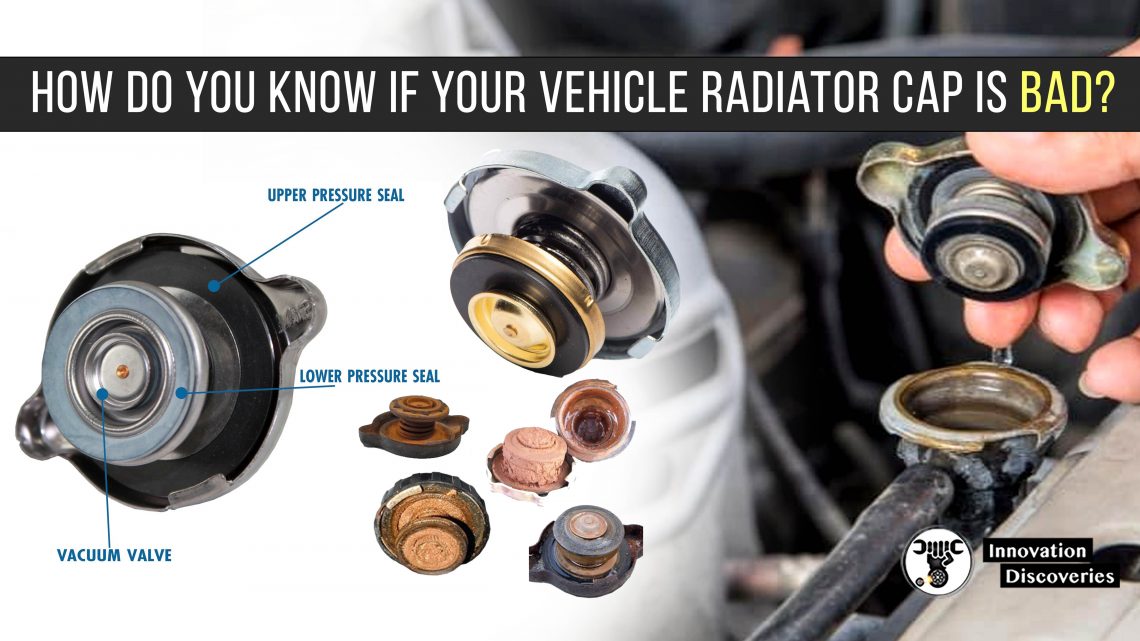

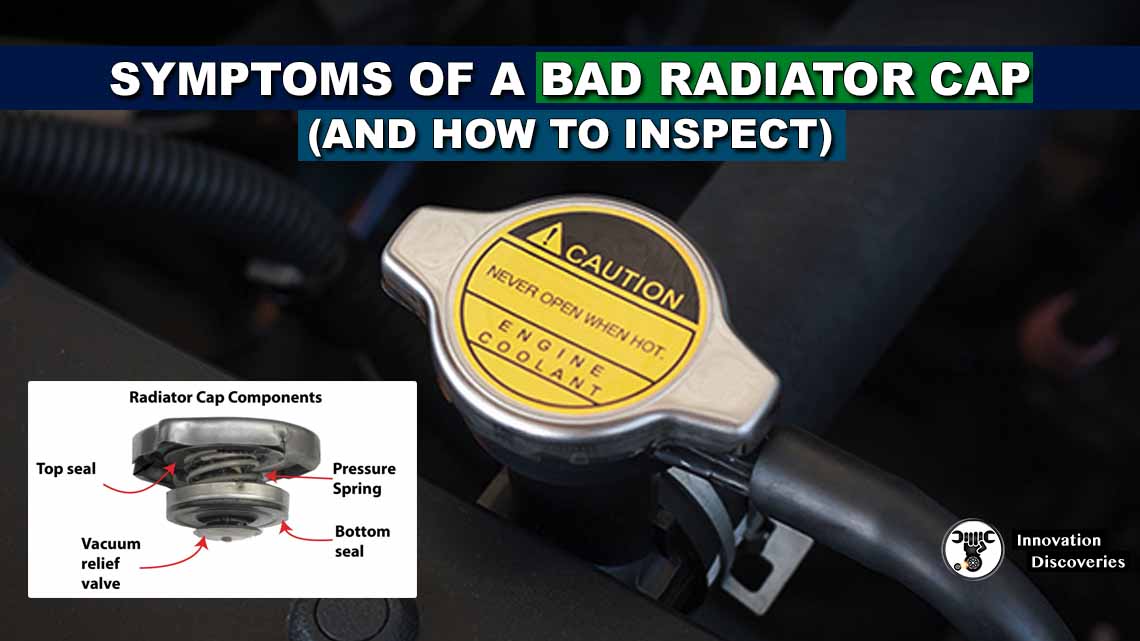

As coolant gets hot, it expands. Since the cooling system is sealed, this expansion causes an increase in pressure in the cooling system, which is normal and part of the design.

When coolant is under pressure, the temperature where the liquid begins to boil is considerably higher.

This pressure, coupled with the higher boiling point of ethylene glycol, allows the coolant to safely reach temperatures in excess of 250 degrees.

The radiator pressure cap is a simple device that will maintain pressure in the cooling system up to a certain point.

If the pressure builds up higher than the set pressure point, there is a spring-loaded valve, calibrated to the correct pounds per square inch (psi), to release the pressure.

Water Pump:

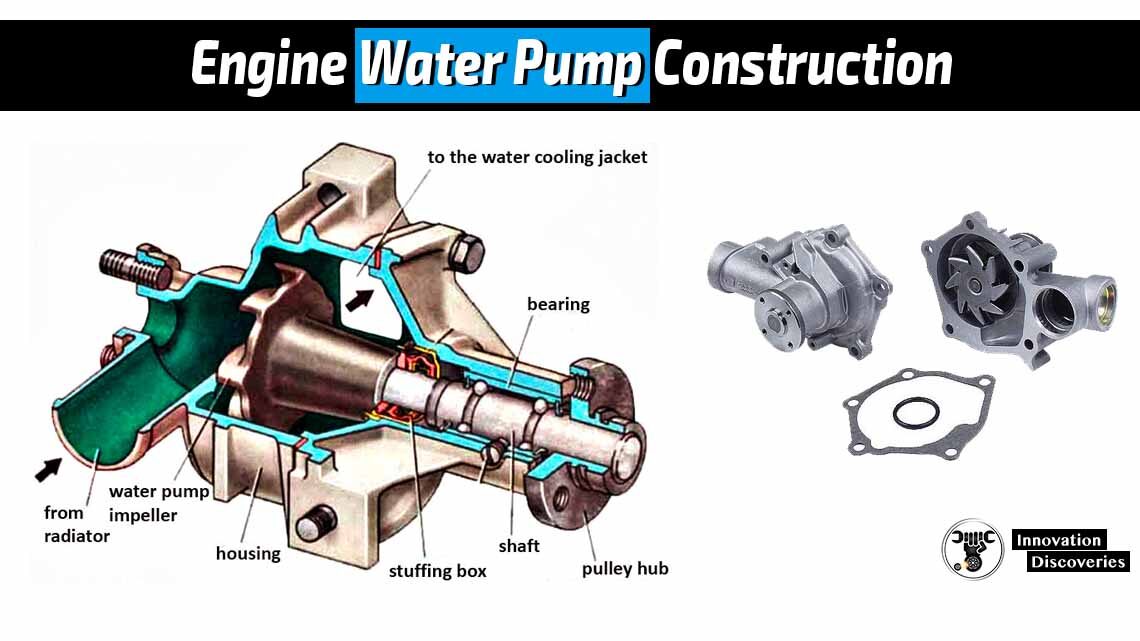

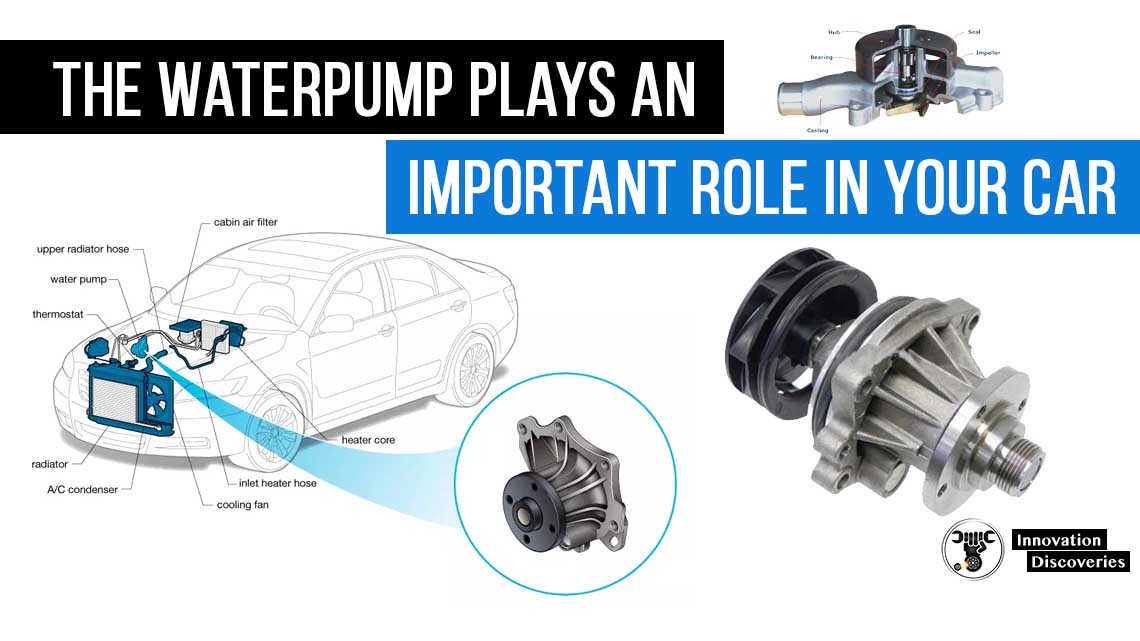

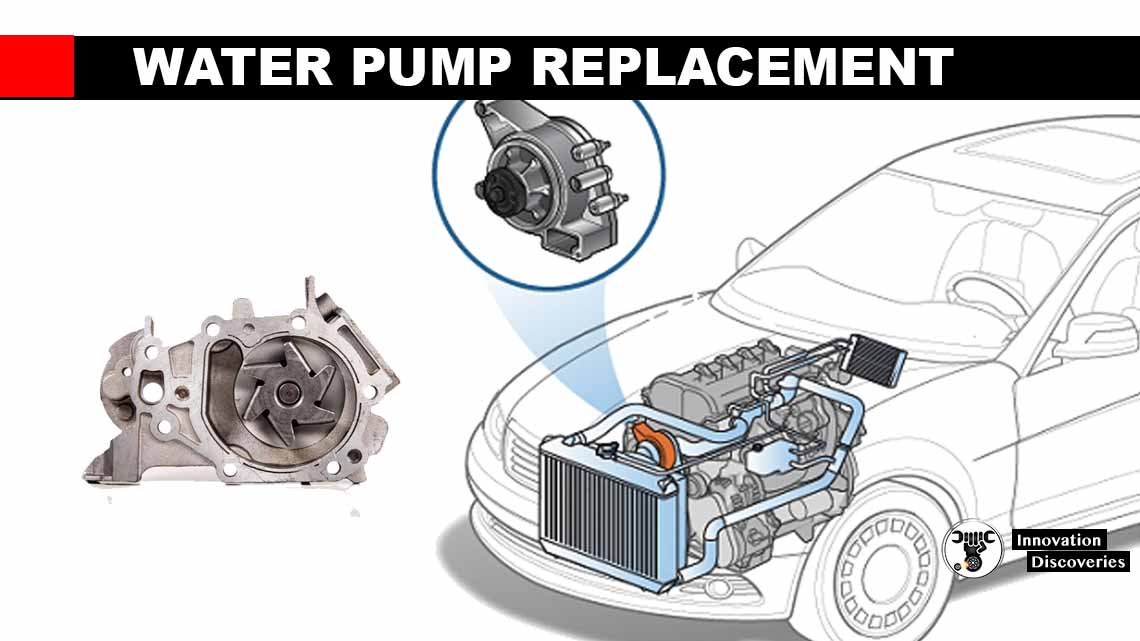

A water pump is a simple device that will keep the coolant moving as long as the engine is running. It is usually mounted on the front of the engine and turns whenever the engine is running.

The water pump is made up of a housing, usually made of cast iron or cast aluminium, and an impeller mounted on a spinning shaft with a pulley attached to the shaft on the outside of the pump body.

A seal keeps fluid from leaking out of the pump housing past the spinning shaft.

The impeller uses centrifugal force to draw the coolant in from the lower radiator hose and send it under pressure into the engine block.

There is a gasket to seal the water pump to the engine block and prevent the flowing coolant from leaking out where the pump is attached to the block.

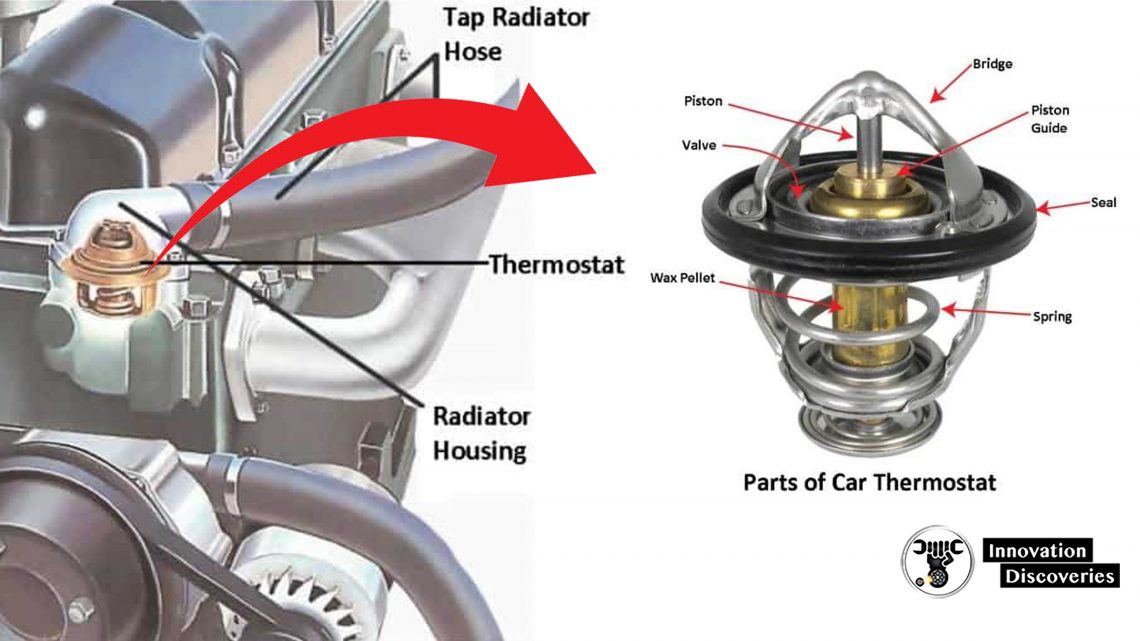

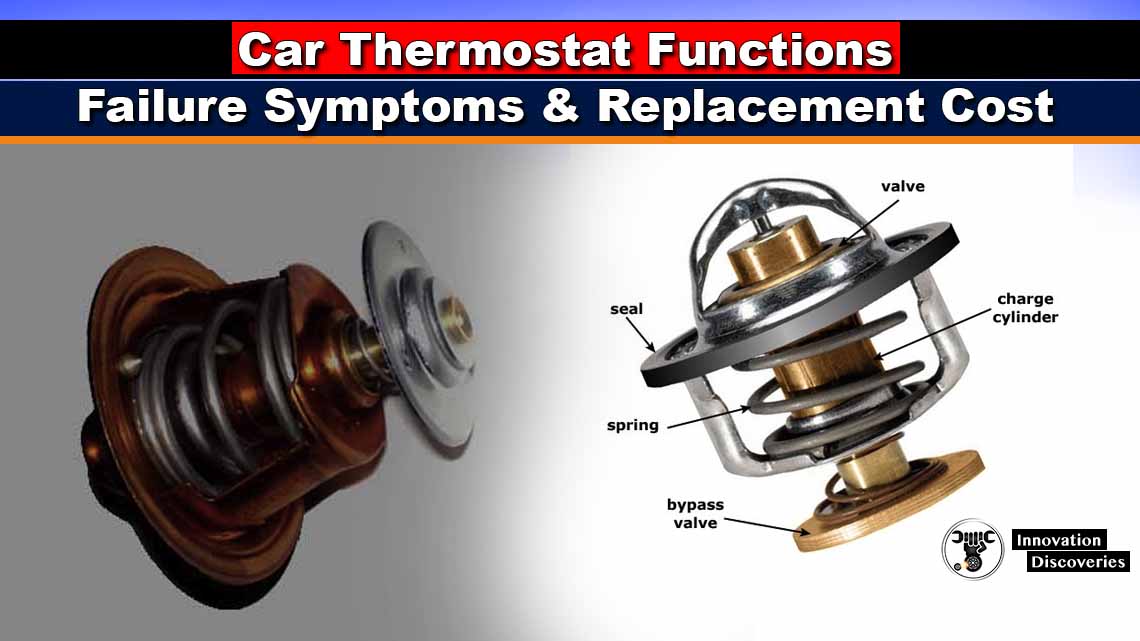

Thermostat:

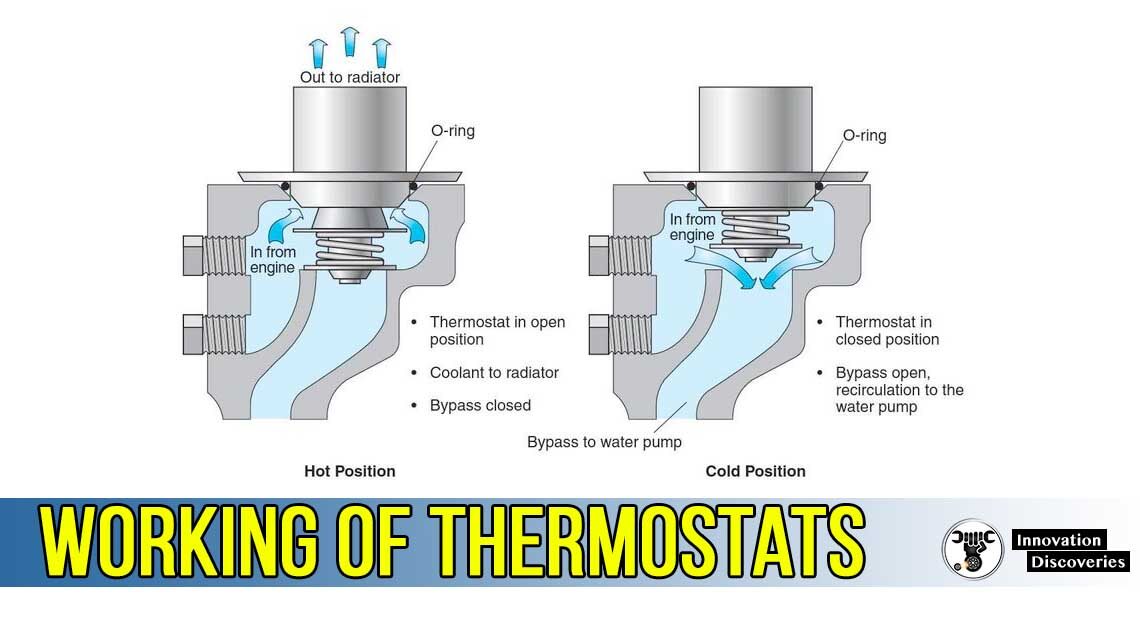

The thermostat is simply a valve that measures the temperature of the coolant and, if it is hot enough, opens it to allow the coolant to flow through the radiator.

If the coolant is not hot enough, the flow to the radiator is blocked and fluid is directed to a bypass system that allows the coolant to return directly back to the engine.

The bypass system allows the coolant to keep moving through the engine to balance the temperature and avoid hot spots.

Because flow to the radiator is blocked, the engine will reach operating temperature sooner and, on a cold day, will allow the heater to begin supplying hot air to the interior more quickly.

Bypass System:

This is a passage that allows the coolant to bypass the radiator and return directly back to the engine.

Some engines use a rubber hose or a fixed steel tube. In other engines, there is a cast-in passage built into the water pump or front housing.

In any case, when the thermostat is closed, coolant is directed to this bypass and channelled back to the water pump, which sends the coolant back into the engine without being cooled by the radiator.

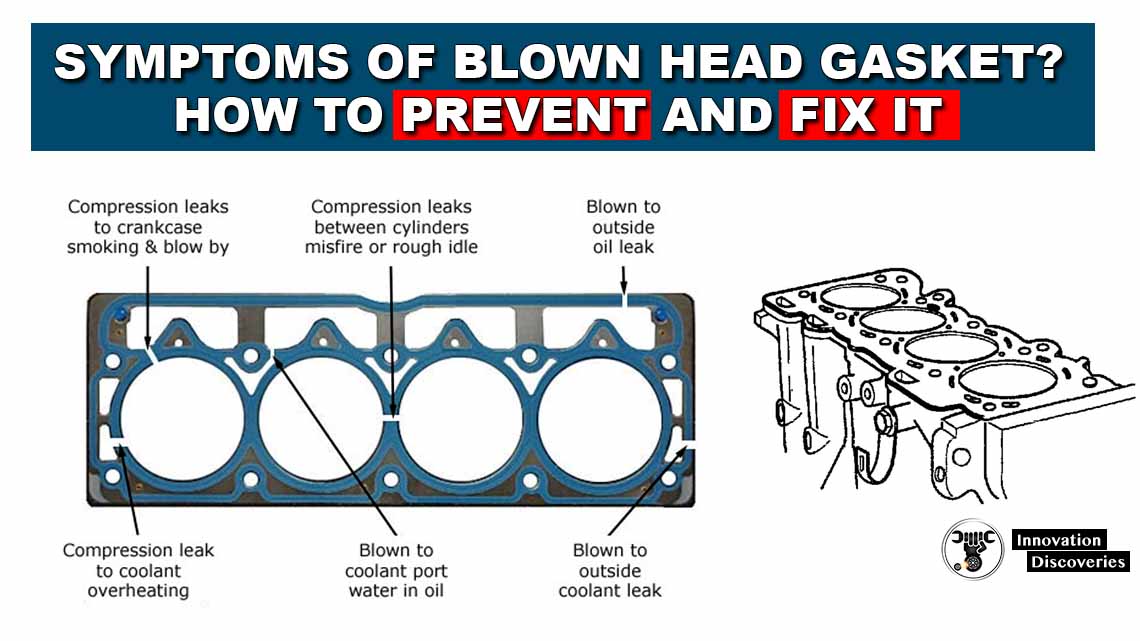

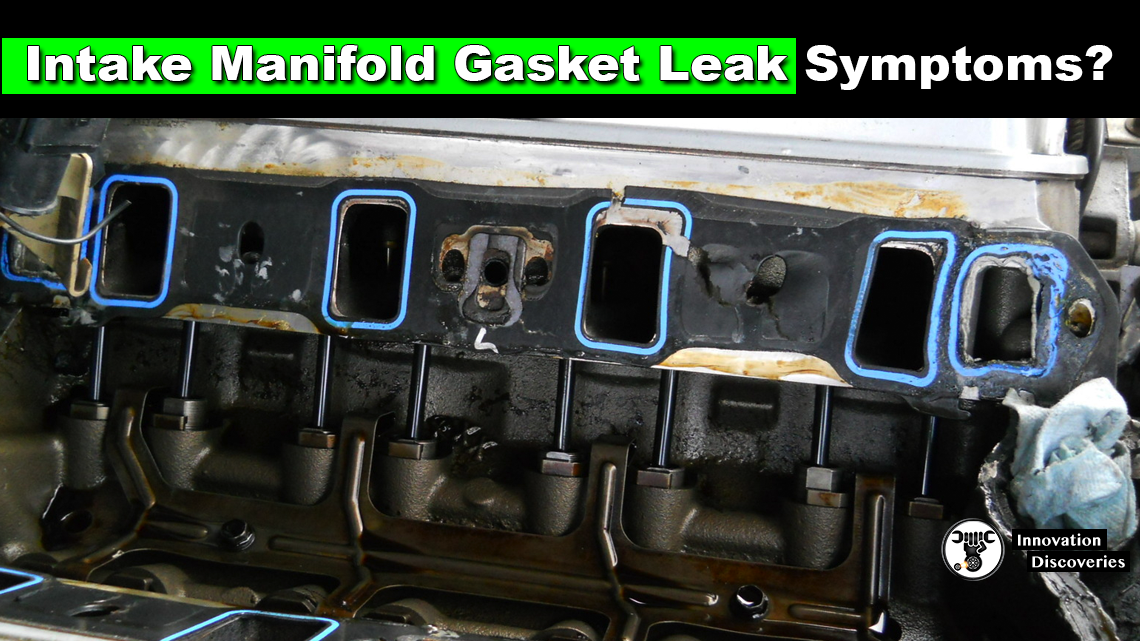

Head Gaskets and Intake Manifold Gaskets:

All internal combustion engines have an engine block and one or two cylinder heads.

The mating surfaces where the block and head meet are machined flat for a close, precision fit.

But no amount of careful machining will allow them to be completely watertight or be able to hold back combustion gases from escaping past the mating surfaces.

To seal the block to the heads, we use a head gasket. The head gasket has several things it needs to seal against.

The main thing is the combustion pressure on each cylinder.

Oil and coolant must easily flow between the block and head, and it is the job of the head gasket to keep these fluids from leaking out or into the combustion chamber, or each other for that matter.

READ MORE:

- HOW TO CHOOSE THE RIGHT GASKETS

- WHAT ARE THE INTAKE MANIFOLD GASKET LEAK SYMPTOMS?

- DETECTING HEAD GASKET ISSUES AND THE SOLUTION

- SHOULD I GET A TRANSMISSION FLUSH? REASONS TO GET A TRANSMISSION FLUSH

Visit Forum

Visit Our Friendly Website