If it never rained, we could build perfectly smooth roads and tires without tread design. Tires in contact with the road would produce a lot less noise and fewer vibrations.

However, the need for grip on the wet ground requires “rough” roads and tread patterns that drain away water to retain a dry contact patch.

In addition, roads feature a series of obstacles, such as bumps, manhole covers, pavement joints, and speed bumps.

Tires are flexible objects which are never perfectly round and which need to be distorted to grip road surfaces.

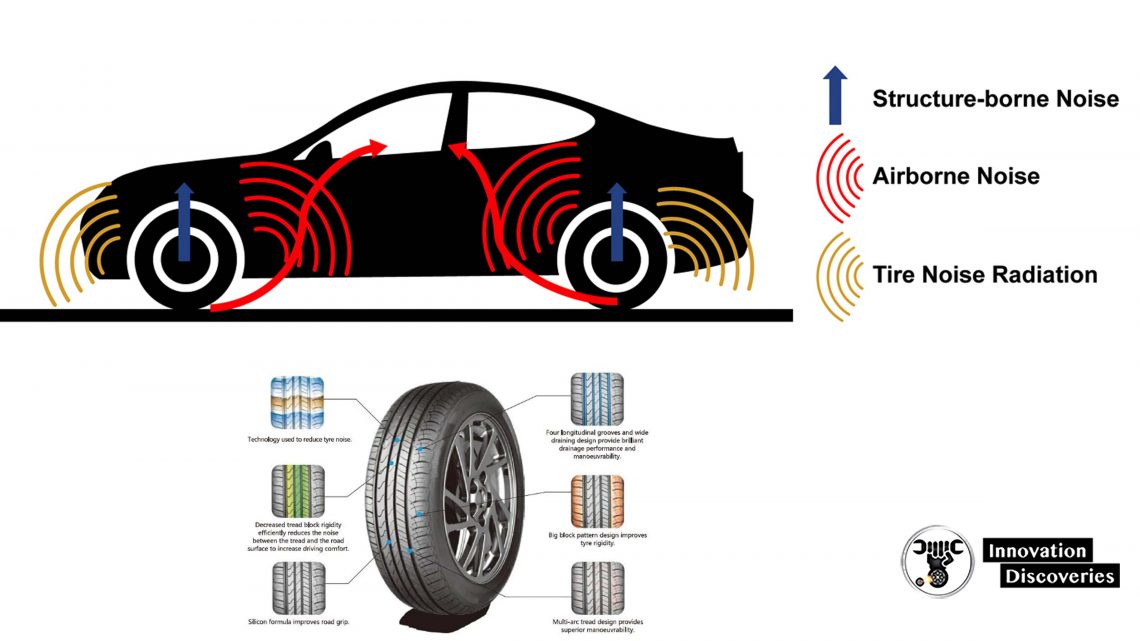

The combination of the tire’s distortion and road surface irregularities produces small shocks in the contact patch, which can make the tire and the vehicle vibrate.

When propagated to people inside or outside the vehicle, these vibrations can be most disturbing and also induce fatigue.

Improving mechanical and acoustic comfort, therefore, lies in designing tires that dampen the impact of road surface irregularities and produce less noise for enhanced driving pleasure.

Comfort

Comfort is a performance that is defined as a subjective expression of the pleasure felt by the user inside the vehicle and involves a number of vibrations:

- jolts from bumpy roads ;

- isolated obstacles (manhole covers, pavement joints, etc.) ;

- discomfort caused by the tires, wheels or fitting ;

Improving comfort, therefore, involves designing a tire that can ease the vibrations within the frequency range of human perception.

One of the ways of achieving this is to prevent the natural vibration mode of the tire and the vehicle from coinciding.

More information about

Vibration:

When a body undergoes a shock, it starts to vibrate.

A vibration is an alternating movement around a position of equilibrium. It is defined by its amplitude and frequency.

Natural Vibration Mode:

Any object is capable of vibrating at many different frequencies if forced to do so.

However, each object favours the frequencies which for a given force produce the largest vibration amplitudes.

These are the natural frequencies, also known as resonance frequencies.

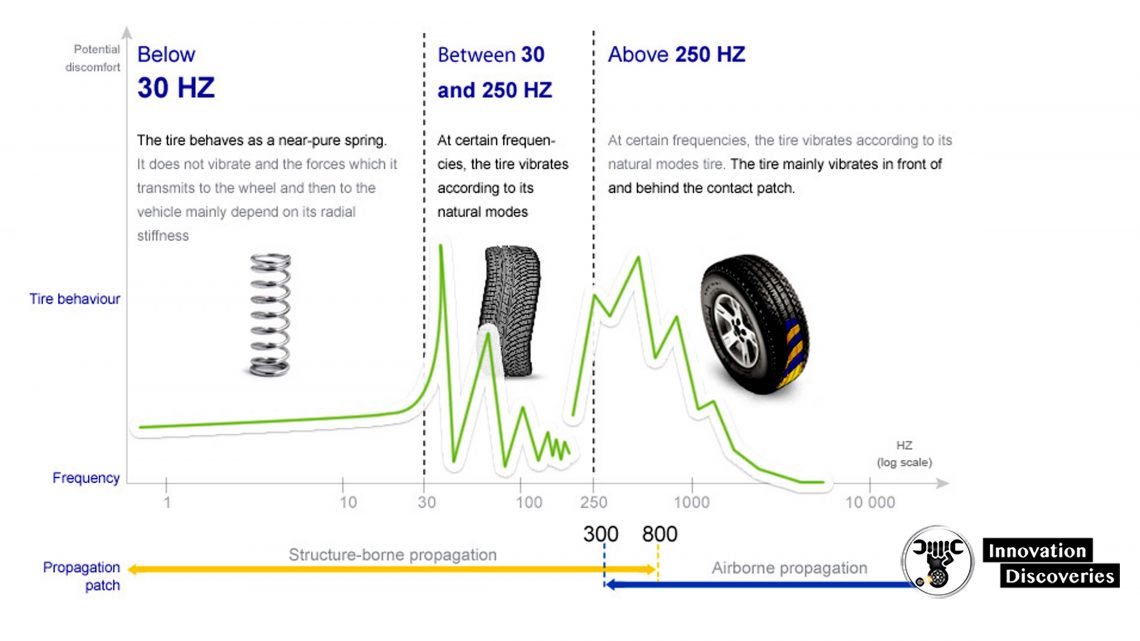

The tire: a vibration filter

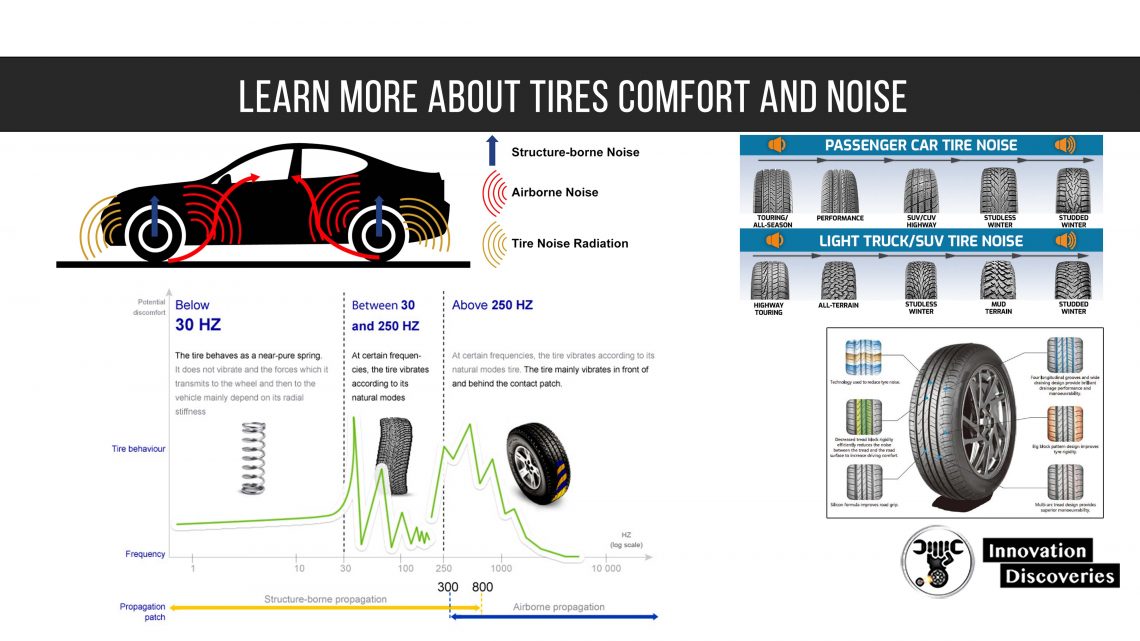

When rolling, the road surface and tread pattern excite the tire over a wide frequency range.

The tire transmits part of this excitation to the vehicle. Depending on the frequency, the tire can filter and dampen the vibrations or amplify them.

To understand the role of tires in mechanical and acoustic comfort, it is necessary to understand the vibratory behaviour of the tire throughout this frequency range.

Noise

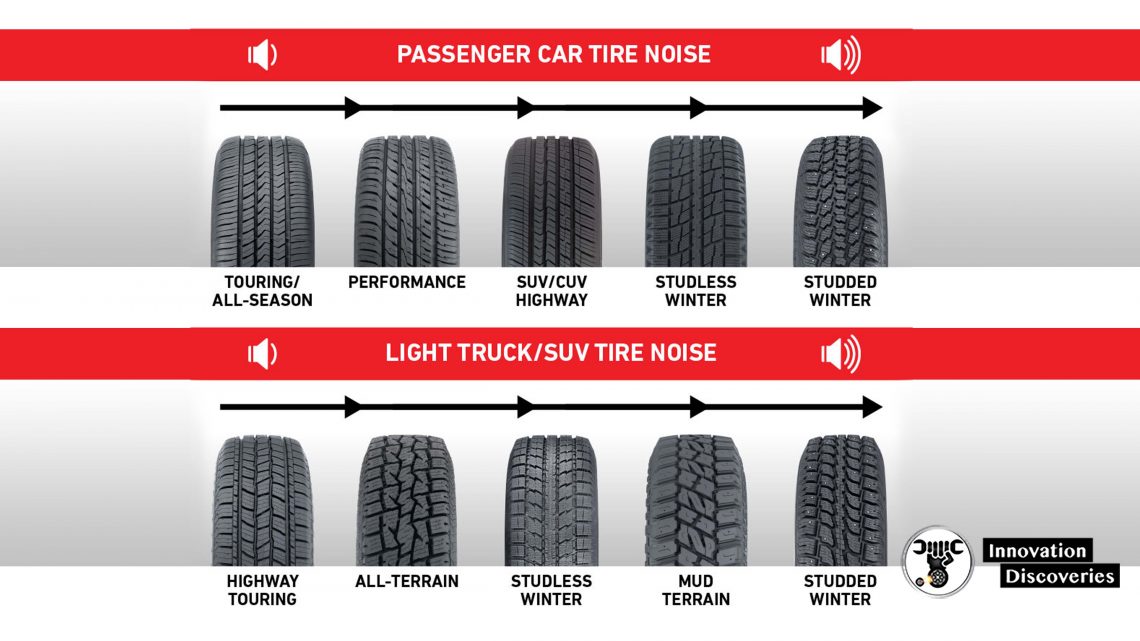

The noise produced by a moving car can affect two types of people:

- The driver and passengers; are known as interior noise.

- Those living and working in buildings close to the road; are known as exterior noise.

The expression “exterior noise” can mean two things, either the exterior noise standardized by regulations (e.g. the labelling standard) or exterior noise required by manufacturers.

The tire, noise maker

Sounds are situated within the audible range (20 to 20 000Hz).

In addition to different types of road surfaces, speed, temperature and tire/vehicle pairing, the tire itself creates noise:

- The tread blocs successively hitting the road surface lead to rhythmic percussion. A tread design made up of short, repetitive patterns will generate a whine.

- During their contact with the road surface, the rubber elements of the tread design are affected by micro-slippage. The slippage generates audible sounds known as sizzling.

- In the grooves of the tread in contact with the road surface, the air is successively imprisoned compressed and then released. This results in a hiss also known as sizzling.

- Very heavy stresses during cornering, acceleration or braking result in significant slippage of the rubber on the road surface. The intense vibration of the rubber creates a characteristic squealing sound.

How the tread block design is laid out is therefore crucial for reducing tire/road contact noise.

It is a good idea to have a varied design, featuring patterns of different sizes.

“Full-scale” tests

Before launching, all new tires have to undergo a battery of tests to ensure that tires fitted on vehicles will meet noise/comfort requirements in “real-life situations”.

Tests are carried out both on machines and on driving tracks. Sensors are placed alongside the tracks to measure exterior noise.

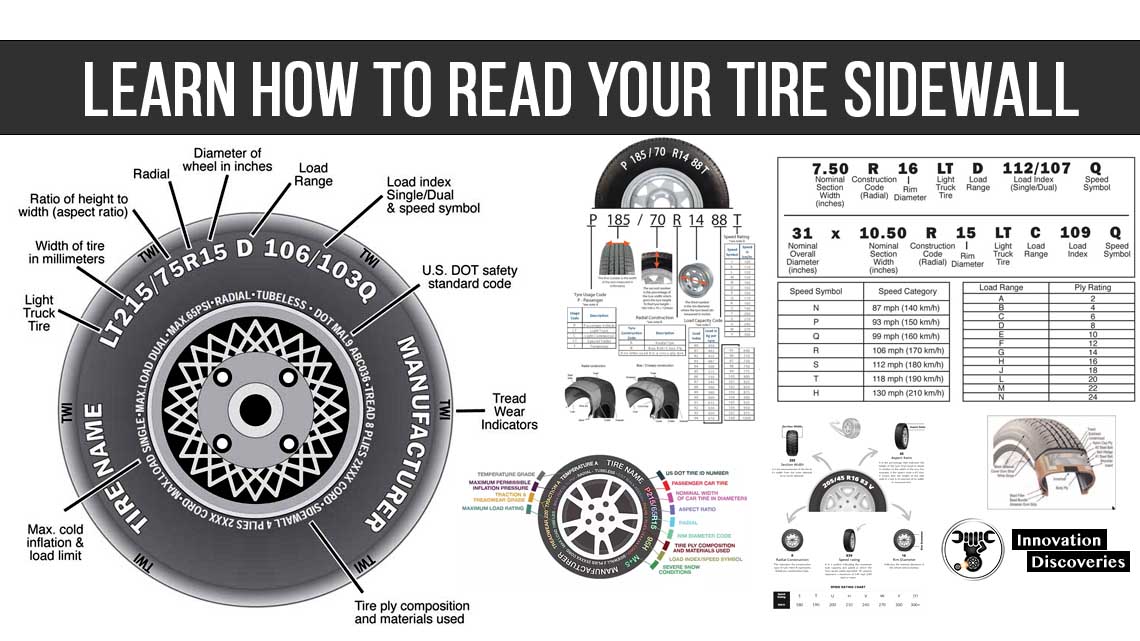

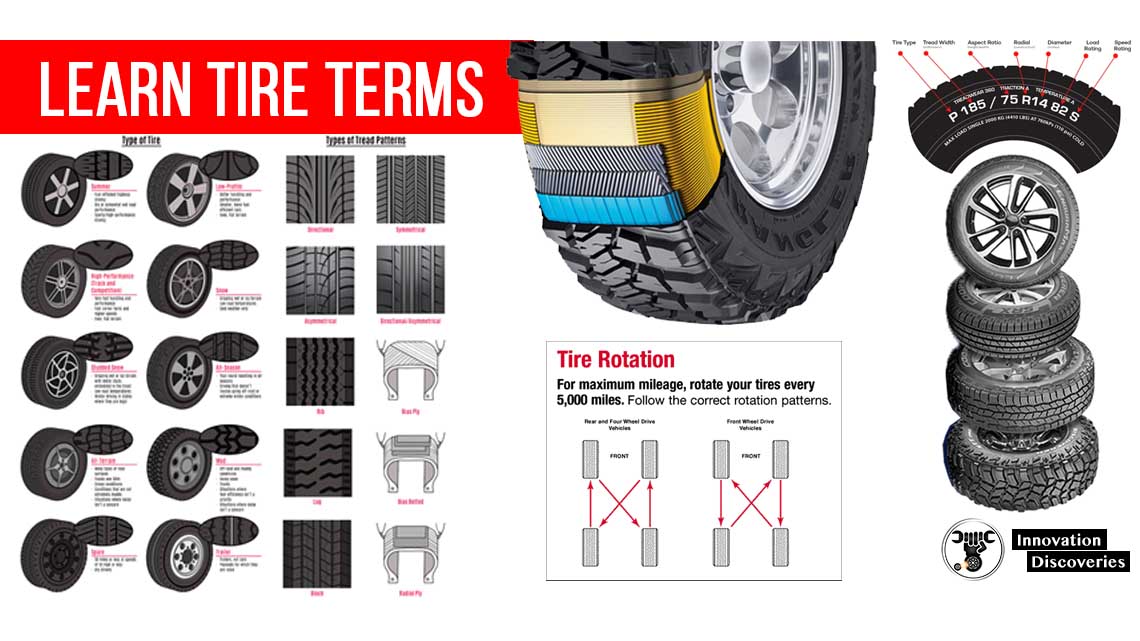

READ: Learn How to Read Your Tire Sidewall

Visit Forum

Visit Our Friendly Website