Introduction

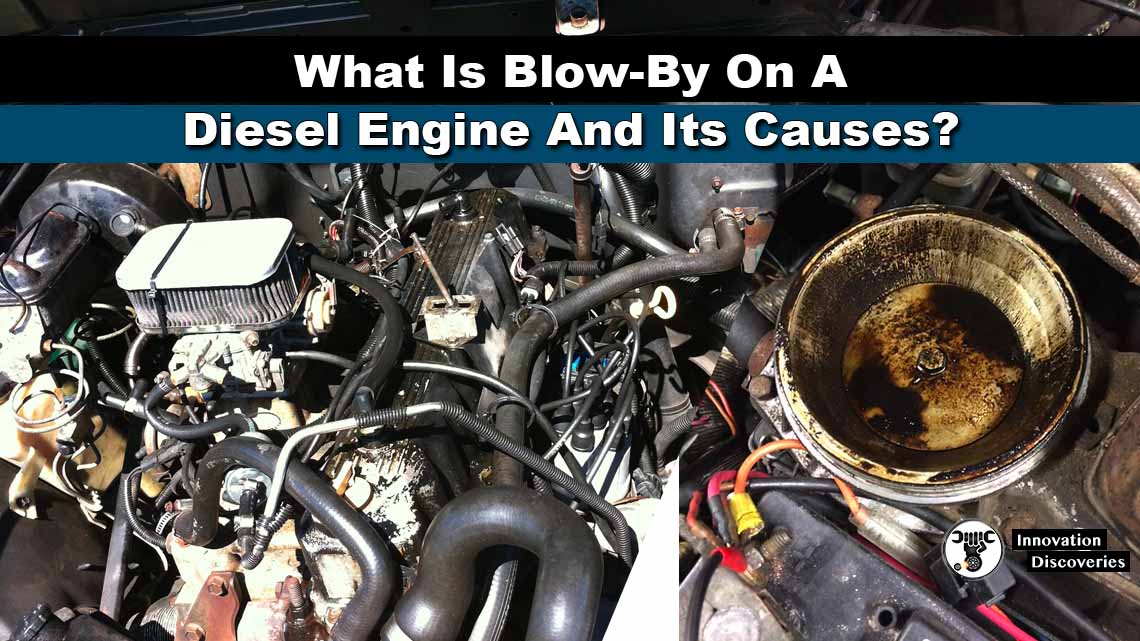

Diesel engines are marvels of engineering, known for their durability and efficiency. However, like any complex machinery, they can experience issues over time. One common problem that can affect diesel engines is blow-by.

In this article, we’ll delve into what blow-by is, its causes, and potential solutions.

What is Blow-By?

Blow-by refers to the phenomenon where combustion gases, along with other byproducts, escape from the combustion chamber of an internal combustion engine, such as a diesel engine, into the crankcase.

In a diesel engine, the combustion process generates high-pressure and high-temperature gases that, under normal circumstances, should be contained within the combustion chamber.

However, when these gases leak past the piston rings and enter the space between the piston and the cylinder wall, blow-by occurs.

Causes of Blow-By:

Worn Piston Rings:

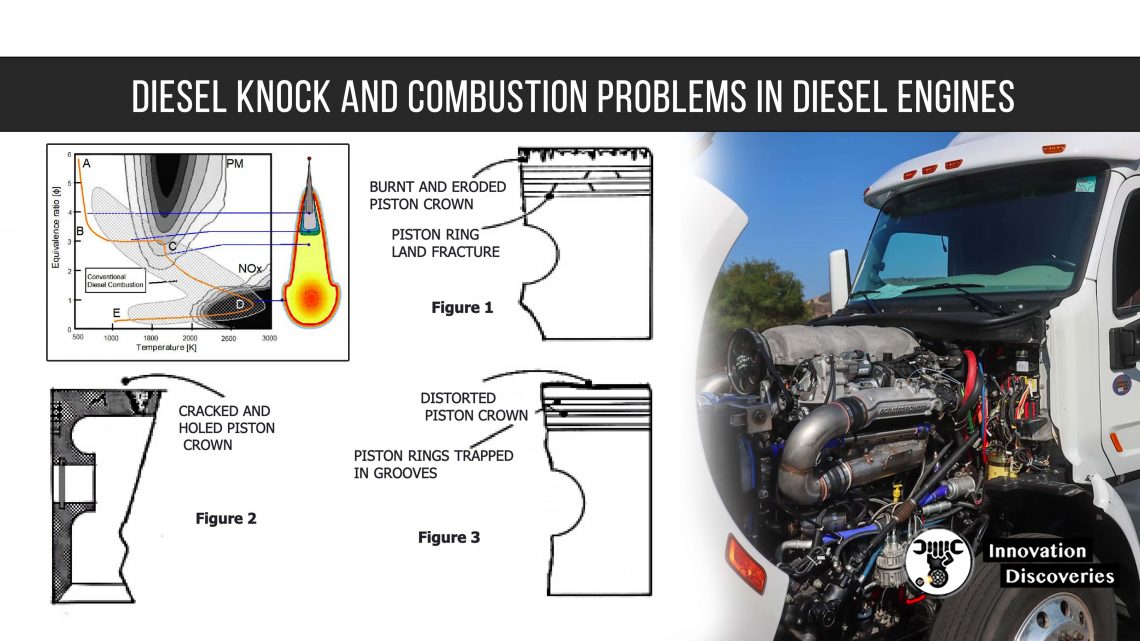

Over time, the piston rings, which play a crucial role in sealing the combustion chamber, can wear down due to the intense conditions within the engine. As they lose their ability to maintain a proper seal, blow-by can occur.

Cylinder Wall Wear:

The cylinder walls also experience wear and tear. When they become worn or damaged, the seal between the piston rings and the cylinder wall weakens, enabling combustion gases to bypass the rings and enter the crankcase.

Incorrect Installation:

Proper engine assembly is vital. Incorrectly installed piston rings or improperly honed cylinder walls can lead to blow-by problems. Rings that aren’t seated correctly or cylinder walls with an incorrect surface finish can contribute to blow-by.

Excessive Cylinder Pressure:

Aggressive engine tuning or faulty fuel injection systems can lead to extremely high combustion pressures. These pressures can force more gases past the piston rings and into the crankcase.

Poor Maintenance:

Neglecting regular maintenance, such as infrequent oil changes or the use of low-quality oil, can result in deposits building up on piston rings and cylinder walls. This buildup can compromise the effectiveness of the rings and contribute to blow-by.

Engine Wear and Tear:

As an engine ages, various components experience wear and tear. This includes the piston rings and other sealing components, which can result in decreased sealing efficiency and an increased likelihood of blow-by.

Crankcase Ventilation System Issues:

Diesel engines are equipped with a crankcase ventilation system designed to manage blow-by gases by directing them out of the engine. If this system becomes clogged or malfunctions, blow-by gases can accumulate within the crankcase.

The Impact of Blow-By:

Excessive blow-by can lead to various issues in a diesel engine:

Increased Oil Consumption:

Blow-by gases can lead to increased oil consumption as they contaminate the engine oil with combustion byproducts.

Reduced Efficiency:

Blow-by decreases engine efficiency by allowing combustion gases to escape without contributing to power generation.

Engine Performance Degradation:

Blow-by can result in reduced engine performance and power output.

Oil Contamination:

Blow-by gases can mix with the engine oil, leading to the formation of harmful deposits and reduced oil quality.

Solutions and Prevention:

Regular Maintenance:

Adhering to a strict maintenance schedule that includes regular oil changes and using high-quality oil can help prevent blow-by issues.

Proper Assembly:

Ensuring piston rings are correctly installed and cylinder walls are properly honed during engine assembly is crucial.

Quality Lubrication:

Using high-quality engine oil with the right viscosity and additives can improve the longevity of piston rings and cylinder walls.

Addressing Engine Wear:

Regularly inspecting and replacing worn components can minimize the effects of engine wear on blow-by.

Crankcase Ventilation:

Ensure the crankcase ventilation system is functioning properly and is free from obstructions.

In conclusion, blow-by is a common issue in diesel engines that can stem from various causes.

Understanding the root causes and implementing preventive measures through proper maintenance, quality lubrication, and addressing engine wear can help mitigate blow-by problems, ensuring the longevity and optimal performance of your diesel engine.

See More:

- What is Hydraulic Hammer and how does it work?

- How a diesel engine works

- Checking engine dampers

- How Often To Change Air Filter In Car? The Answer

Discover More:

Visit Forum

Visit Our Friendly Website

2 Comments