An automobile requires high torque when climbing hills and when starting, even though they are performed at low speeds.

Read: STARTING AND CHARGING SYSTEMS

On other hand, when running at high speeds on level roads, high torque is not required because of momentum.

So the requirement of a device occurs, which can change the vehicle’s torque and its speed according to road condition or when the driver needs it.

Read: HOW THE STARTING SYSTEM WORKS

This device is known as a transmission box or gearbox.

The function of transmission box (gearbox) in an automobile:

The transmission box which is also known as the gearbox is the second element of the power train in an automobile.

It is used to change the speed and torque of a vehicle according to a variety of road and load conditions.

The transmission box changes the engine speed into torque when climbing hills and when the vehicle required.

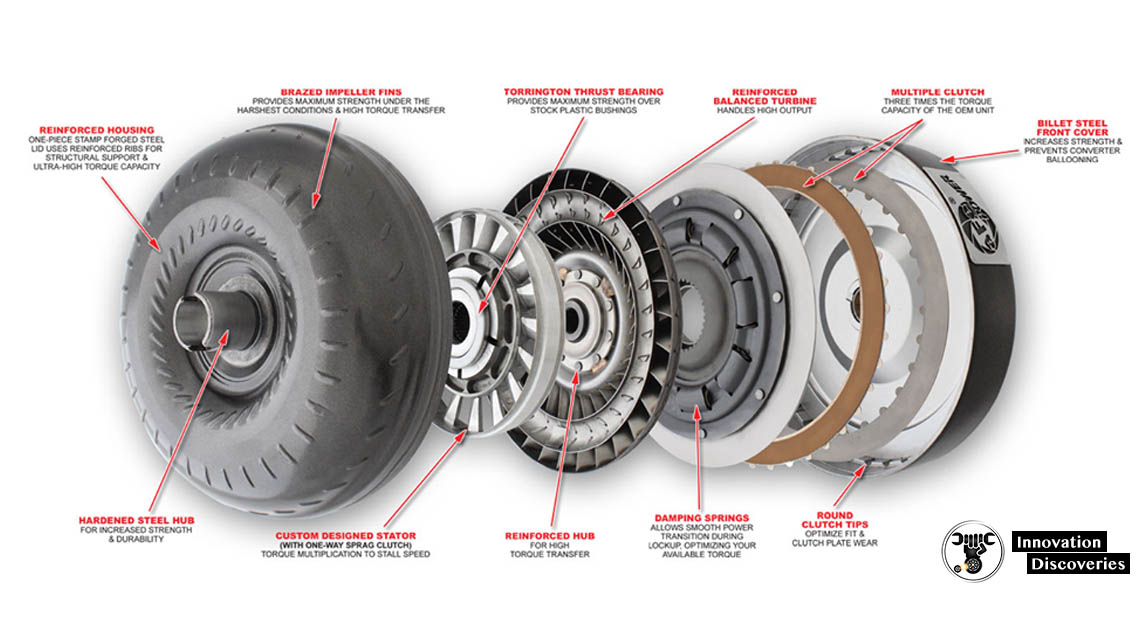

Sometimes it is known as a torque converter.

The main functions of a gearbox are as follow:

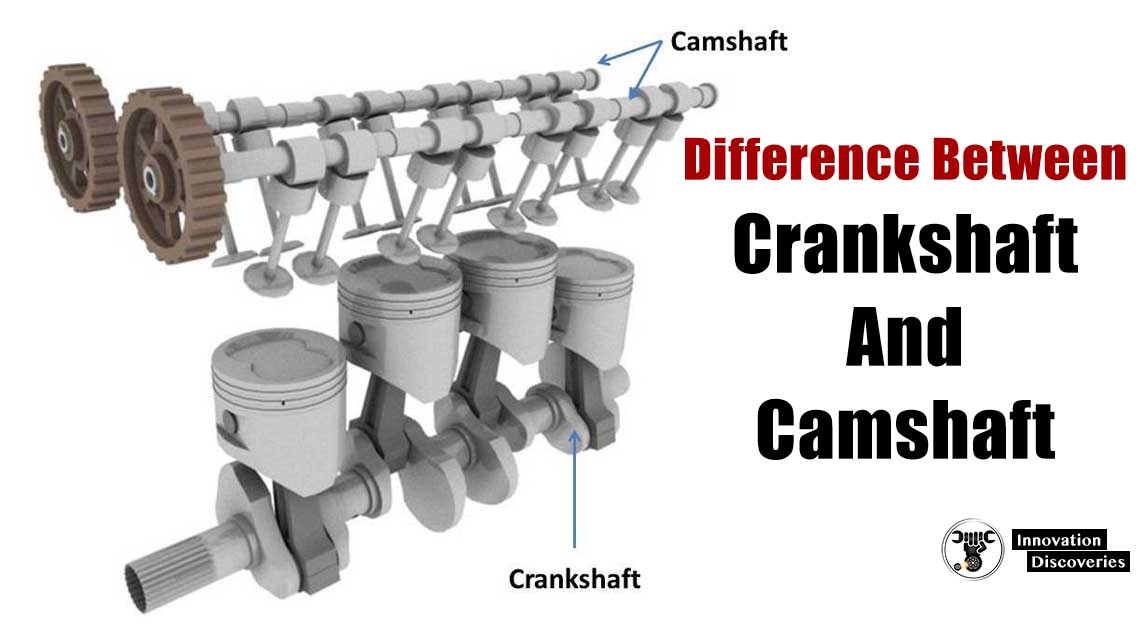

- Provide the torque needed to move the vehicle under a variety of road and load conditions. It does this by changing the gear ratio between the engine crankshaft and vehicle drive wheels.

- Be shifted into reverse so the vehicle can move backwards.

- Be shifted into neutral for starting the engine.

TORQUE CONVERTER: FUNCTIONS, PARTS, WORKING PRINCIPLES, AND TYPES

Read More:

- THE GEARBOX (TRANSMISSION)

- COMMON FAULTS IN THE 6-SPEED DSG TRANSMISSION

- HOW TO FIX AN AUTOMATIC TRANSMISSION THAT IS SLIPPING

- TRANSMISSION | SYNCHRONIZERS CONSTRUCTION

- HOW LONG DOES IT TAKE TO REPLACE A TRANSMISSION? TRUTH TO KNOW

- REASONS FOR TRANSMISSION SHIFTING HARD FROM 1ST TO 2ND GEAR

- SEALED TRANSMISSIONS: THE COMPREHENSIVE GUIDE

- BAD HABITS THAT AFFECT THE TRANSMISSION LIFE EXPECTANCY

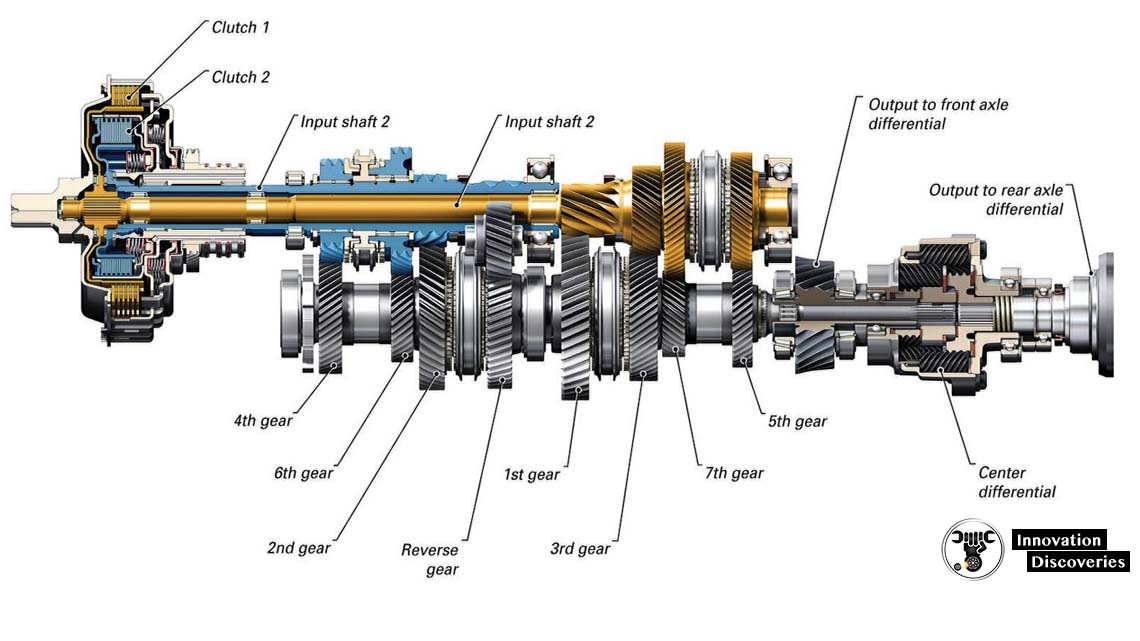

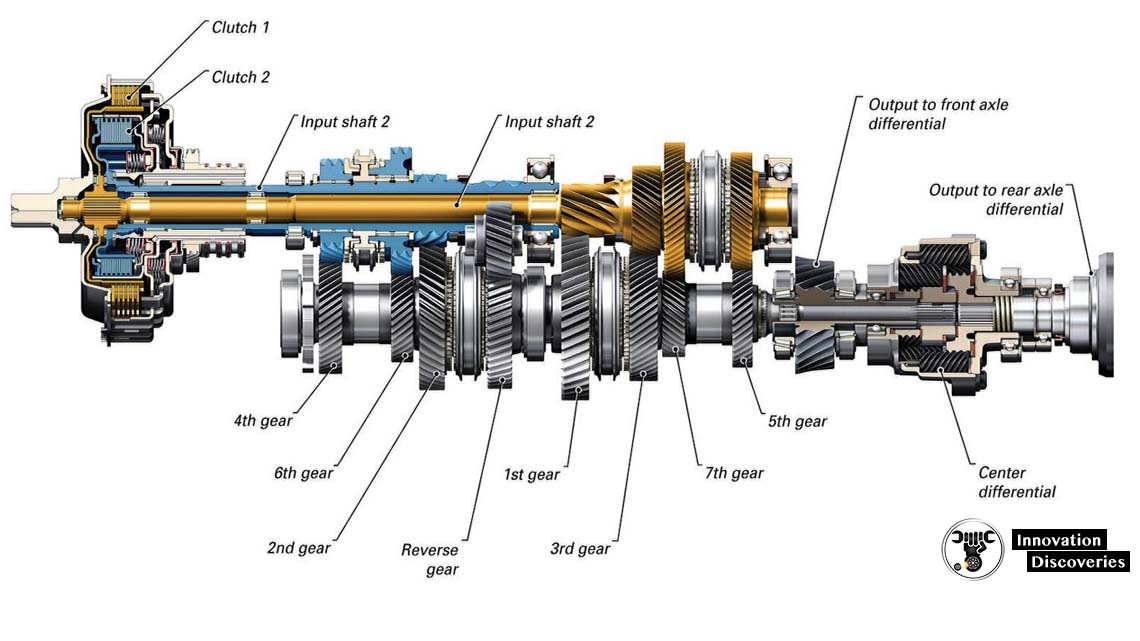

Main components of a gearbox:

In any device, two or more component works together and fulfils the required function.

In a transmission box, four components are required to fulfil its function.

1. Countershaft:

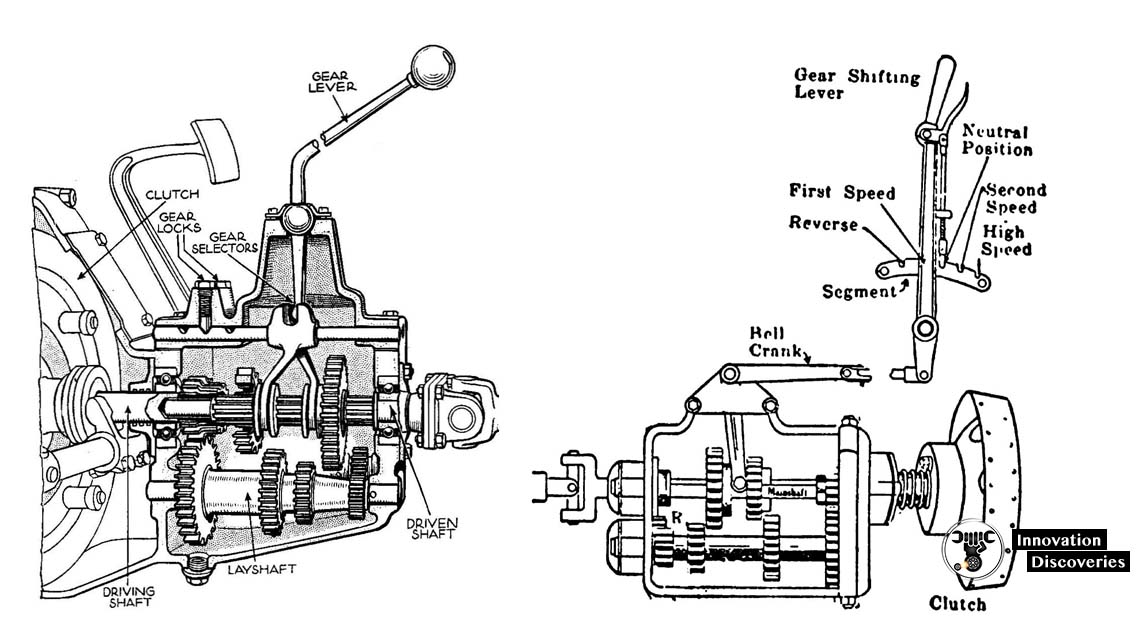

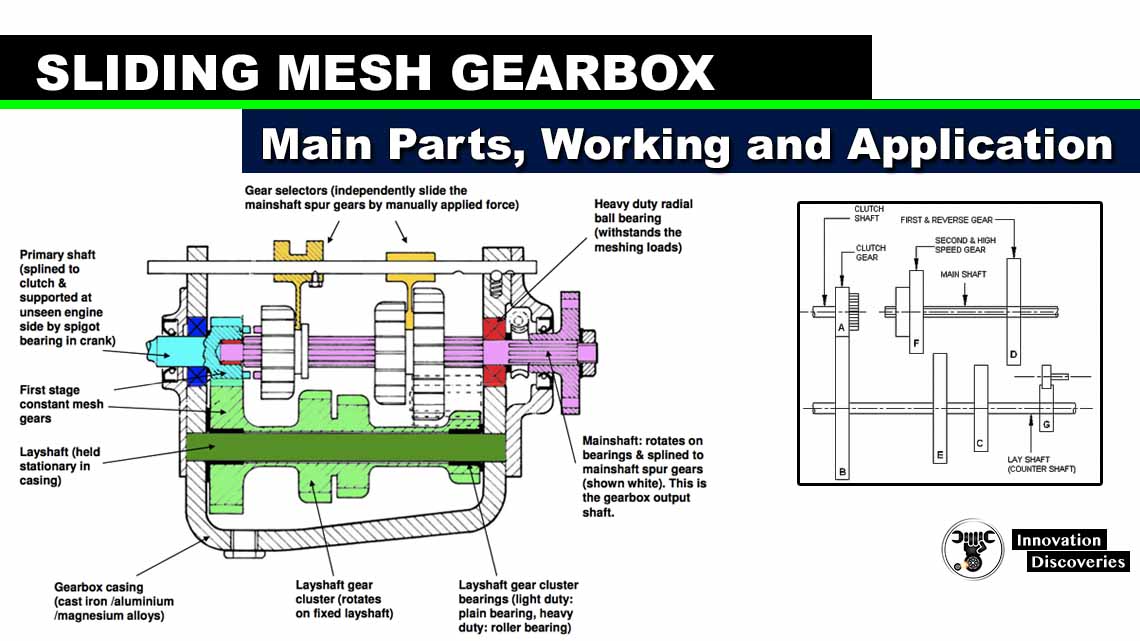

A countershaft is a shaft that connects with the clutch shaft directly.

It contains the gear which connects it to the clutch shaft as well as the main shaft.

It may be run at the engine speed or at lower than engine speed according to gear ratio.

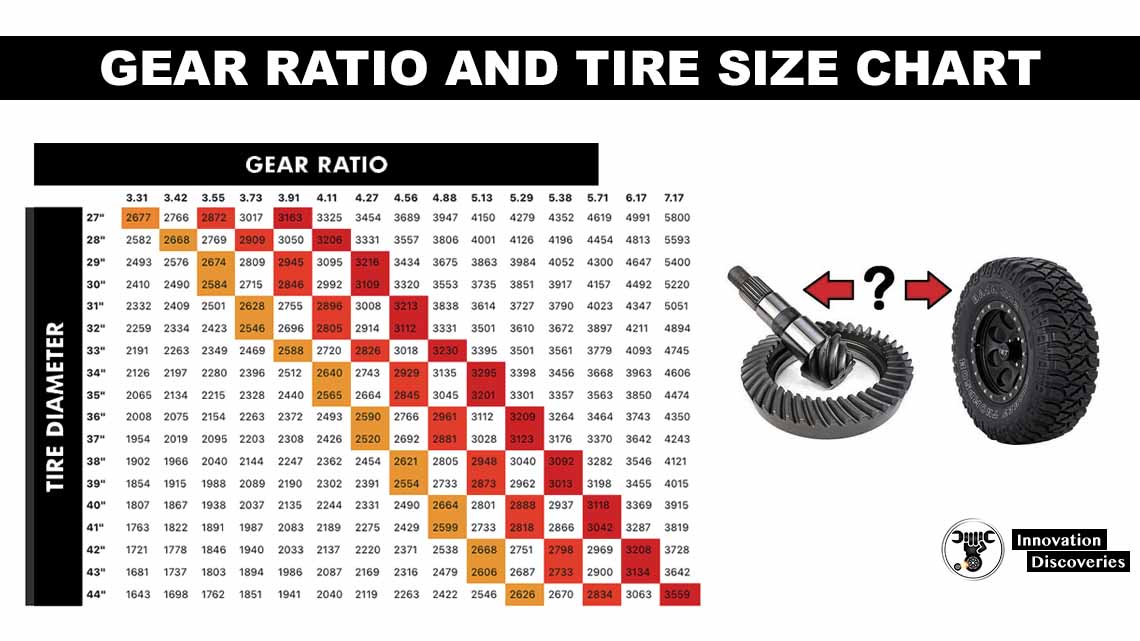

Read: GEAR RATIO AND TIRE SIZE CHART

2. Main shaft:

It is the shaft that runs at the vehicle speed.

It carries power from the countershaft by use of gears and according to the gear ratio, it runs at a different speed and torque compares to the countershaft.

One end of this shaft is connected with the universal shaft.

Download: BASIC SHAFT ALIGNMENT WORKBOOK

Read: 3 CAUSES OF DRIVE SHAFT NOISE (WHEN TURNING, BRAKING OR IN REVERSE)

3. Gears:

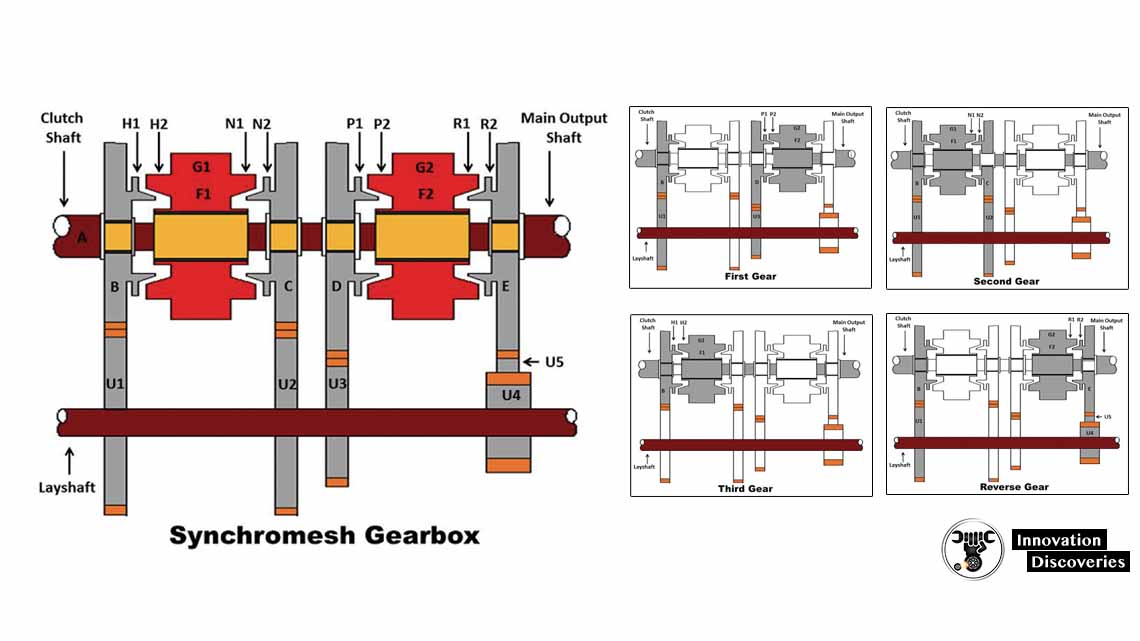

Gears are used to transmit the power from one shaft to another.

WHAT IS DRIVESHAFT? WORKING OF DRIVESHAFT

They are the most useful component of the gearbox because the variation is the torque of the countershaft and the main shaft is depends on the gear ratio.

The gear ratio is the ratio of the driven gear teeth to the driving gear teeth.

If the gear ratio is large than one, the main shaft revolves at a lower speed than the countershaft and the torque of the main shaft is higher than the countershaft.

On the other hand, if the gear ratio is less than one, than the main shaft revolves at a higher speed than the countershaft and the torque of the main shaft is lower than the countershaft.

A small car gearbox contains a four-speed gear ratio and one reverse gear.

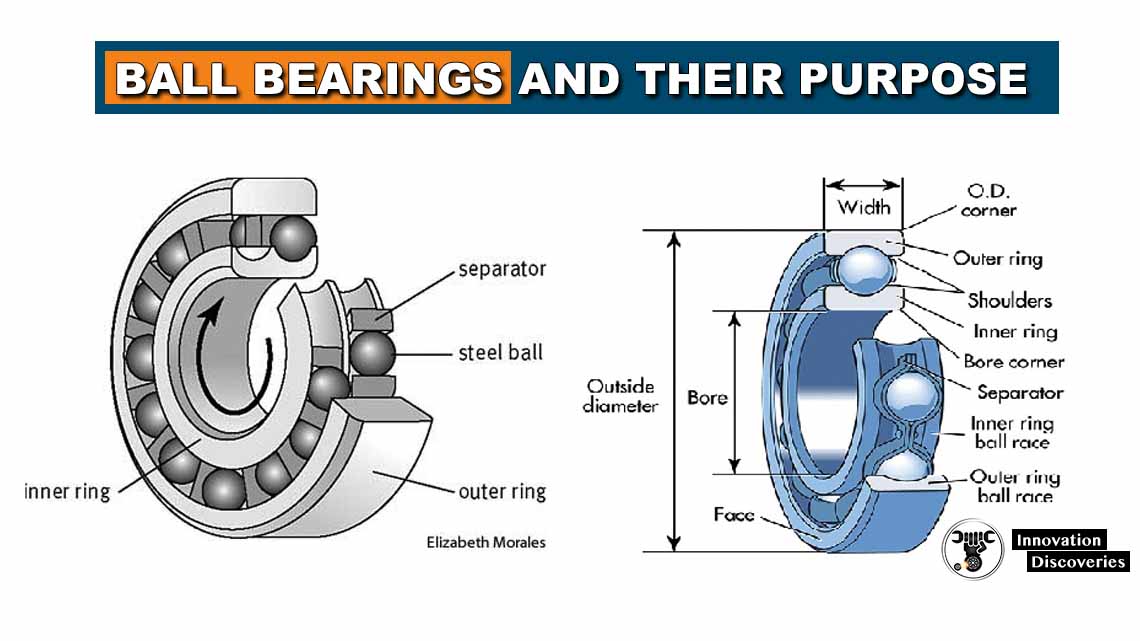

4. Bearings:

Whenever the rotary motion encounters, bearings are required to support the revolving part and reduce the friction.

In the gearbox, both the counter and main shaft are supported by the bearing.

![BEARING | TYPES, APPLICATIONS, FAILURES, SELECTION, ADVANTAGES [FULL GUIDE]](https://innovationdiscoveries.space/wp-content/uploads/2019/10/Bearing1-1024x576.jpg)

Read:

- BEARING | TYPES, APPLICATIONS, FAILURES, SELECTION, ADVANTAGES [FULL GUIDE]

- WHAT ARE BALL BEARINGS AND WHAT IS THEIR PURPOSE?

- HOW LONG CAN YOU DRIVE ON A BAD WHEEL BEARING?

- REPLACING WHEEL BEARINGS ON DRIVEN WHEELS

- HOW TO TELL WHICH WHEEL BEARING IS BAD?

- STRUTS MOUNT AND STRUT BEARING | Q & A

Download:

Working of a principle gearbox:

In a gearbox, the countershaft is mashed to the clutch with the use of a couple of gears.

So, the countershaft is always in running condition.

When the countershaft is brought in contact with the main shaft by use of meshing gears, the main shaft starts to rotate according to the gear ratio.

SLIDING MESH GEARBOX – MAIN PARTS, WORKING AND APPLICATION

When the driver wants to change the gear ratio, simply press the clutch pedal which disconnects the countershaft with an engine and connect the main shaft with the countershaft by another gear ratio by use of a gearshift lever.

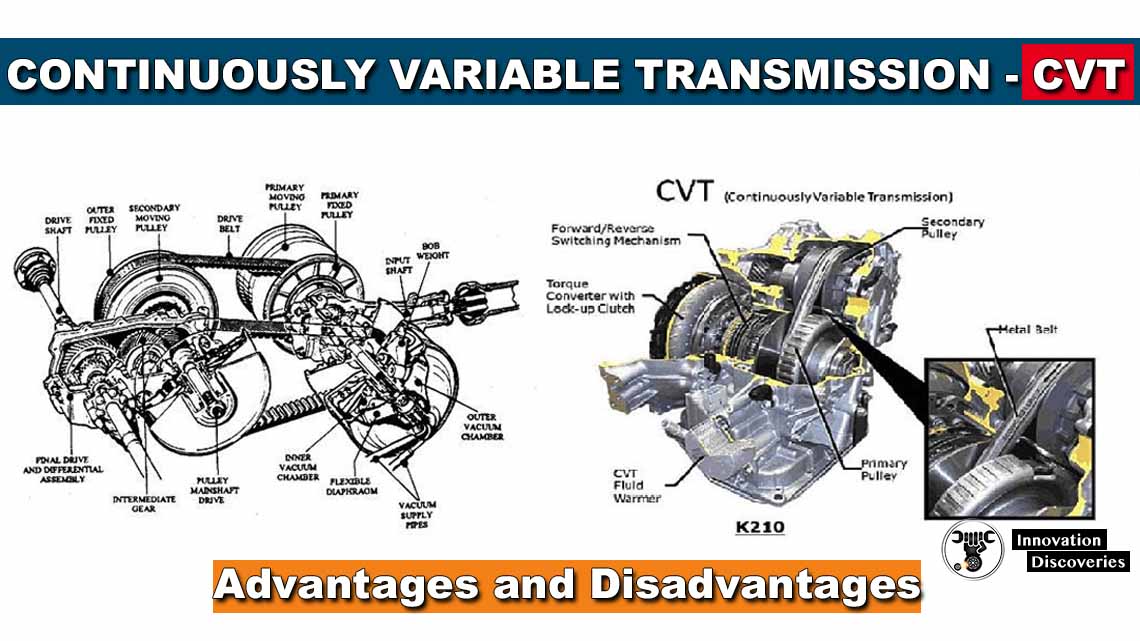

Read: CONTINUOUSLY VARIABLE TRANSMISSION: ADVANTAGES AND DISADVANTAGES

In a gearbox, the gear teeth and other moving metal must not touch.

They must be continuously separated by a thin film of lubricant. This prevents excessive wear and early failure.

Therefore a gearbox runs partially filled with lubricant oil.

FULL NOTES ON SYNCHROMESH GEARBOX

Visit Forum

Visit Our Friendly Website

Awesome post you have written ..Thanks for amazing articles..

I always try to find such post as you written here ..thank you ..😊

Images always good ro understand and terminology of engineering. Nice and helpful articles which give me always comfindent to improve my engineering knowledge.

Very useful content

You explain perfect and i real apriciate that summary.Thank you.